Tundish coating and preparation method thereof

A smear and tundish technology, which is applied to ceramic products, other household appliances, applications, etc., can solve the problems of cracks, collapse, and peeling after the tundish smear is cured, and shortens the online baking time. The effect of shortening construction and maintenance time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

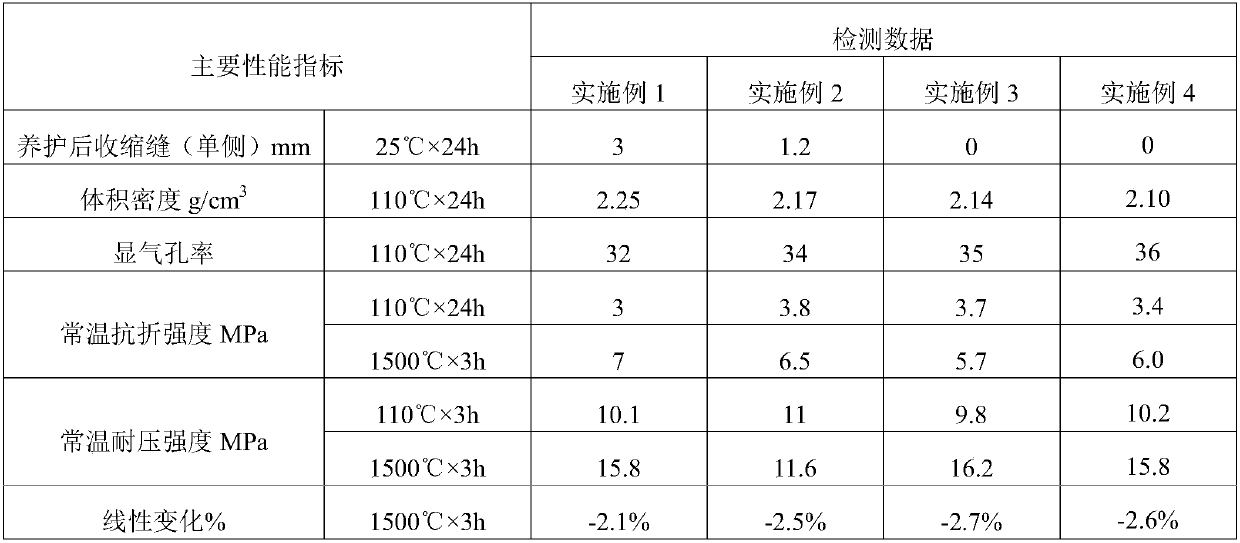

Examples

Embodiment 1

[0023] A preparation method for tundish smear, the steps are as follows:

[0024] (1) Weigh all raw materials according to weight ratio: 20% of sintered magnesia with a particle size of 3 to 1 mm, 32% of sintered magnesia with a particle size of 1 to 0.1 mm, 40% of sintered magnesia with a particle size of not more than 0.075 mm %, 1.5% of paper fiber and organic fiber mixed in a ratio of 10:1, 3% of silicon micropowder, 3.5% of plasticizer (bentonite and Guangxi white clay mixed in a ratio of 1:1), 0.5% of sodium tripolyphosphate, sodium carbonate 0.5%.

[0025] (2) Pour the sintered magnesia particles with a particle size of 3-1 mm and a particle size of 1-0.1 mm into the sand mixer and stir for 3 minutes, then add silicon micropowder and sodium tripolyphosphate and stir for 1 minute to form mixture;

[0026] (3) Add sintered magnesia fine powder, plasticizer fine powder, fiber and sodium carbonate with a particle size not greater than 0.075 mm to the mixture prepared in s...

Embodiment 2

[0028] A preparation method for tundish smear, the steps are as follows:

[0029] (1) Weigh all the raw materials according to weight ratio: 20% of sintered magnesia with a particle size of 3 to 1 mm, 32% of sintered magnesia with a particle size of 1 to 0.1 mm, and 39% of sintered magnesia with a particle size of no more than 0.075 mm %, 1.35% of paper fiber and organic fiber mixed in a ratio of 10:1, 2% of microsilica powder, 2.75% of plasticizer (bentonite and red clay mixed in a ratio of 1:1), 0.4% of sodium hexametaphosphate, and 1.5% of calcium carbonate %.

[0030] (2) Pour the sintered magnesia particles with a particle size of 3-1 mm and a particle size of 1-0.1 mm into the sand mixer and stir for 3 minutes, then add silicon micropowder and sodium tripolyphosphate and stir for 1 minute to form mixture;

[0031] (3) Add sintered magnesia fine powder, plasticizer fine powder, fiber and sodium carbonate with a particle size not greater than 0.075 mm to the mixture prep...

Embodiment 3

[0033] A preparation method for tundish smear, the steps are as follows:

[0034] (1) Weigh all raw materials according to weight ratio: 20% of sintered magnesia with a particle size of 3-1 mm, 32% of sintered magnesia with a particle size of 1-0.1 mm, and 38% of sintered magnesia with a particle size of no more than 0.075 mm. %, 1.2% of paper fiber and organic fiber mixed in a ratio of 10:1, 1% of silicon micropowder, 2% of plasticizer (bentonite and red clay mixed in a ratio of 1:1), 0.3% of sodium hexametaphosphate, 2.5% of magnesium carbonate %.

[0035] (2) Pour the sintered magnesia particles with a particle size of 3-1 mm and a particle size of 1-0.1 mm into the sand mixer and stir for 3 minutes, then add silicon micropowder and sodium tripolyphosphate and stir for 1 minute to form mixture;

[0036] (3) Add sintered magnesia fine powder, plasticizer fine powder, fiber and sodium carbonate with a particle size not greater than 0.075 mm to the mixture prepared in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com