Water and energy saving type sand and stone aggregate washing system and use method thereof

An energy-saving aggregate technology, applied in the field of sand and gravel aggregates, can solve problems such as flocculant accumulation, achieve water saving, reduce system cost, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

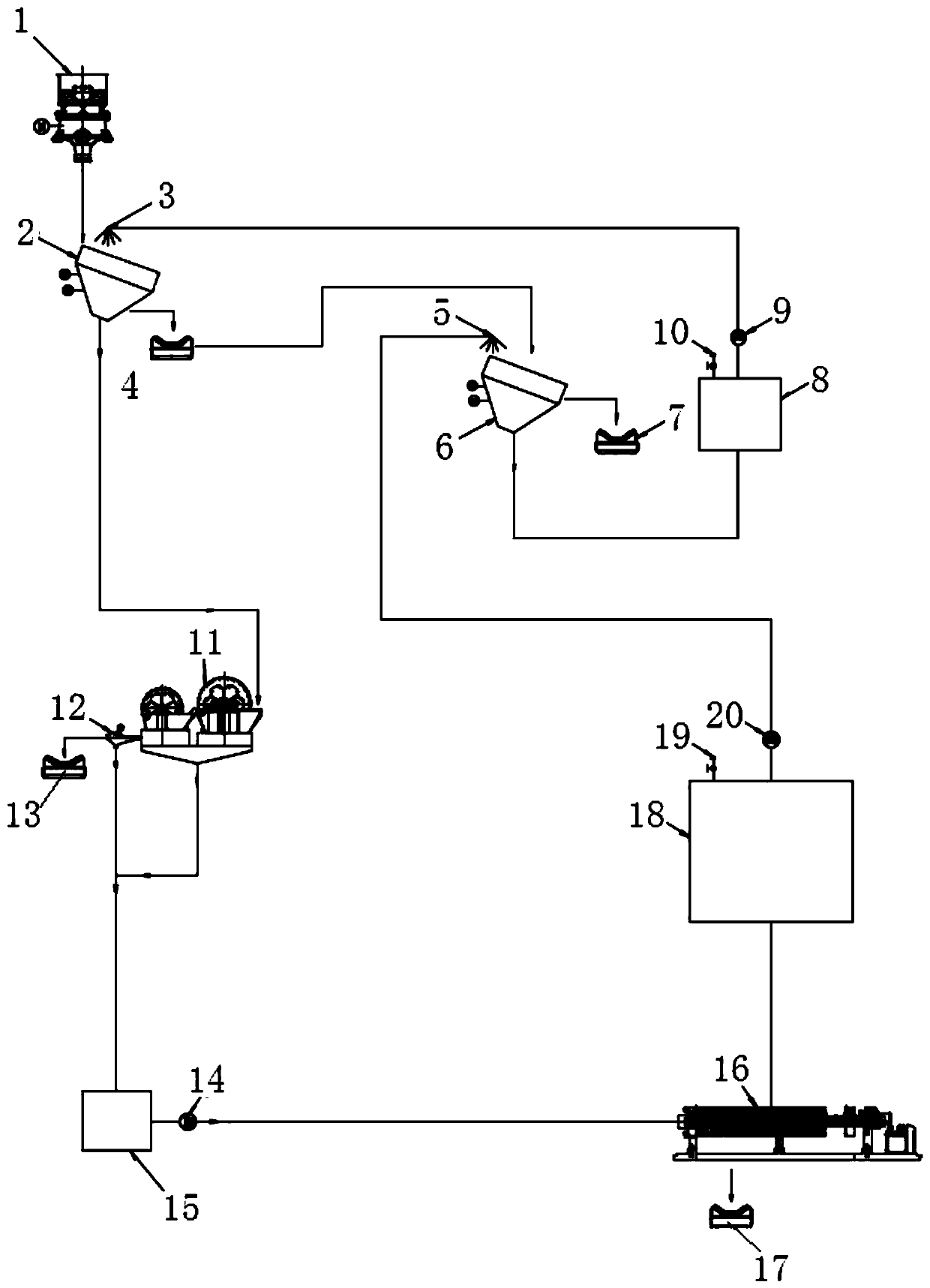

[0019] Embodiment 1: This embodiment is a water-saving and energy-saving sand and gravel aggregate washing system, which includes a crusher 1, an inspection screen 2, a large-diameter anti-blocking nozzle 3, a mixing aggregate belt conveyor 4, a fan-shaped nozzle 5, and a finished product. Sieve 6, finished aggregate belt conveyor 7, light waste water tank 8, light waste water slurry pump 9, sand washing machine 11, dehydration screen 12, finished sand belt conveyor 13, concentrated waste water slurry pump 14, concentrated waste water tank 15, plate Frame filter press 16, filter cake belt conveyor 17, clean water pool 18 and clean water pump 20;

[0020] The discharge port of the crusher 1 is set correspondingly to the feed port of the inspection sieve 2; The feeding end of the mixing aggregate belt conveyor 4 is set correspondingly, the sand-water mixture outlet of the inspection screen 2 is set correspondingly to the feeding port of the sand washing machine 11; the large-dia...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that it also includes a water supply device 10 for the light waste water pool, and the water supply device 10 for the light waste water pool communicates with the light waste water pool 8 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: it also includes a clean water tank replenishment device 19 , and the clean water tank water replenishment device 19 communicates with the clean water tank 18 . Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com