A pressure dividing device for pneumatic vehicles

A technology for pneumatic vehicles and equipment, applied in the directions of brakes, vehicle components, brake transmissions, etc., can solve the problems of difficult coordination, high risk, and low reliability in the coordination of vehicle driving and braking. Maneuverability, low cost, effect of ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

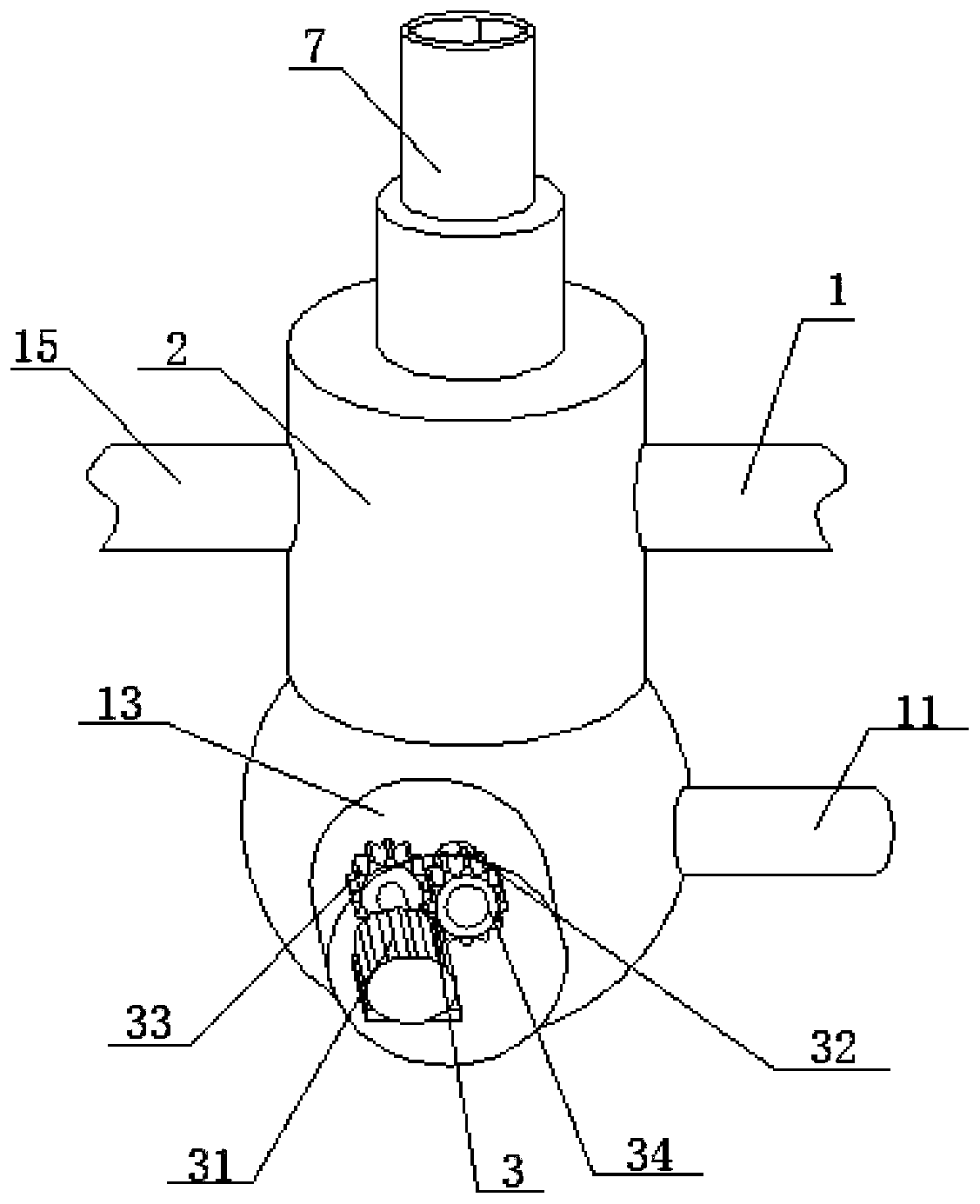

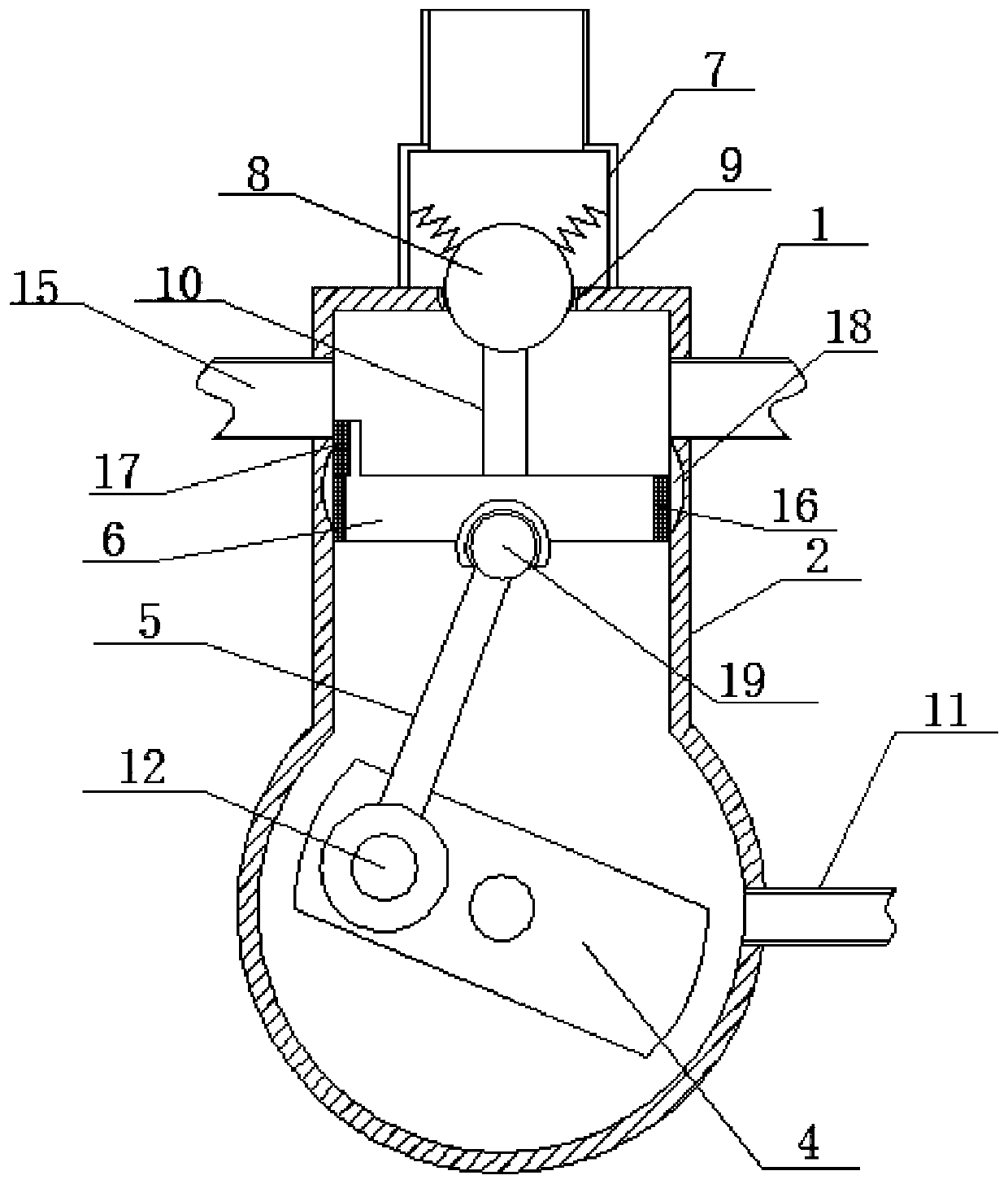

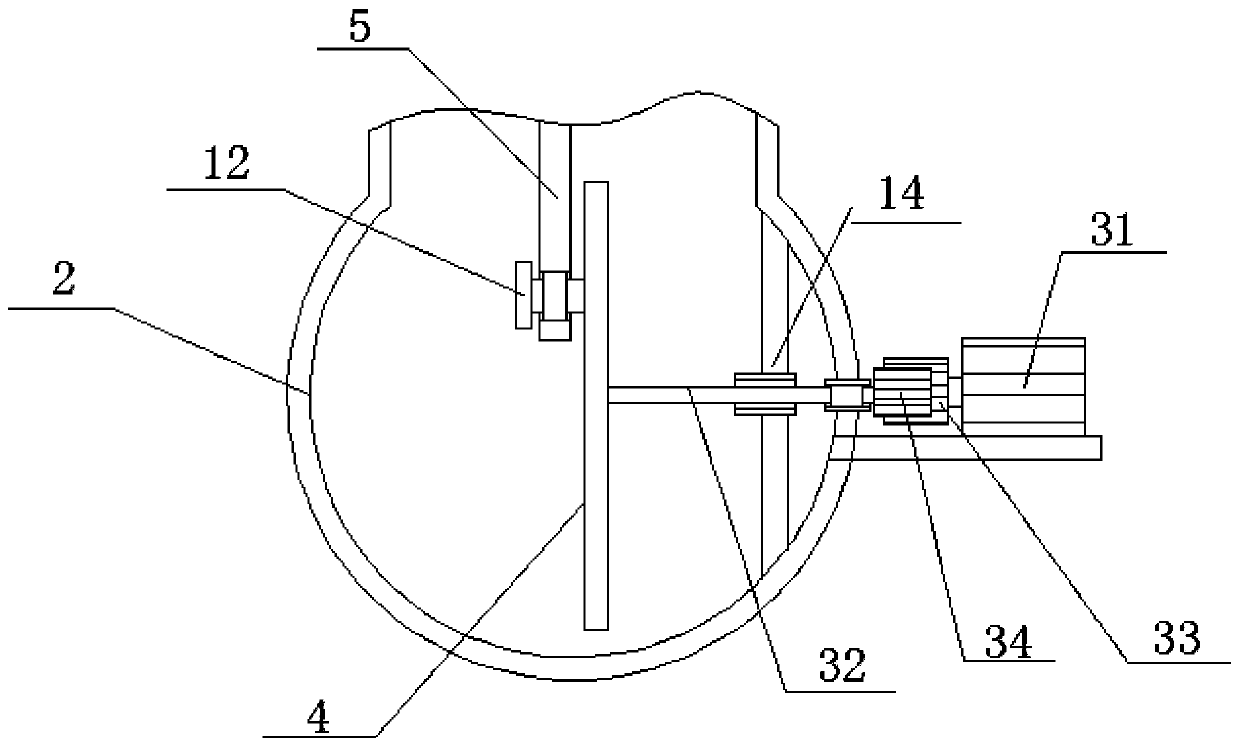

[0027] see Figure 1~3 , in the embodiment of the present invention, a kind of pressure-dividing equipment for pneumatic vehicle, comprises air intake pipe 1, pressure-dividing tank 2, driving air pipe 15, rear brake pipe 7 and front brake pipe 11, it is characterized in that the pressure-dividing The box 2 is provided with a manipulation assembly, one side of the pressure dividing box 2 is provided with the air inlet pipe 1, and the other side of the pressure dividing box 2 is provided with a driving air pipe 15 arranged opposite to the air inlet pipe 1, The driving air pipe 15 communicates with the vehicle power drive mechanism;

[0028] A front brake pipe 11 is communicated with the side of the control assembly on the pressure divider box 2, and the front brake pipe 11 communicates with the braking mechanism of the front wheel of the automobile;

[0029] A rear brake pipe 7 is connected to the side of the pressure divider box 2 away from the steering assembly, and the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com