High-impact-toughness solid weld wire resisting acid liquid corrosion and preparation method thereof

A solid wire, high impact technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problem of not being able to have both high resistance to sulfuric acid and hydrochloric acid corrosion and low temperature impact toughness, to reduce cold crack sensitivity, ensure Sulfuric acid and hydrochloric acid corrosion resistance, carbon equivalent reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

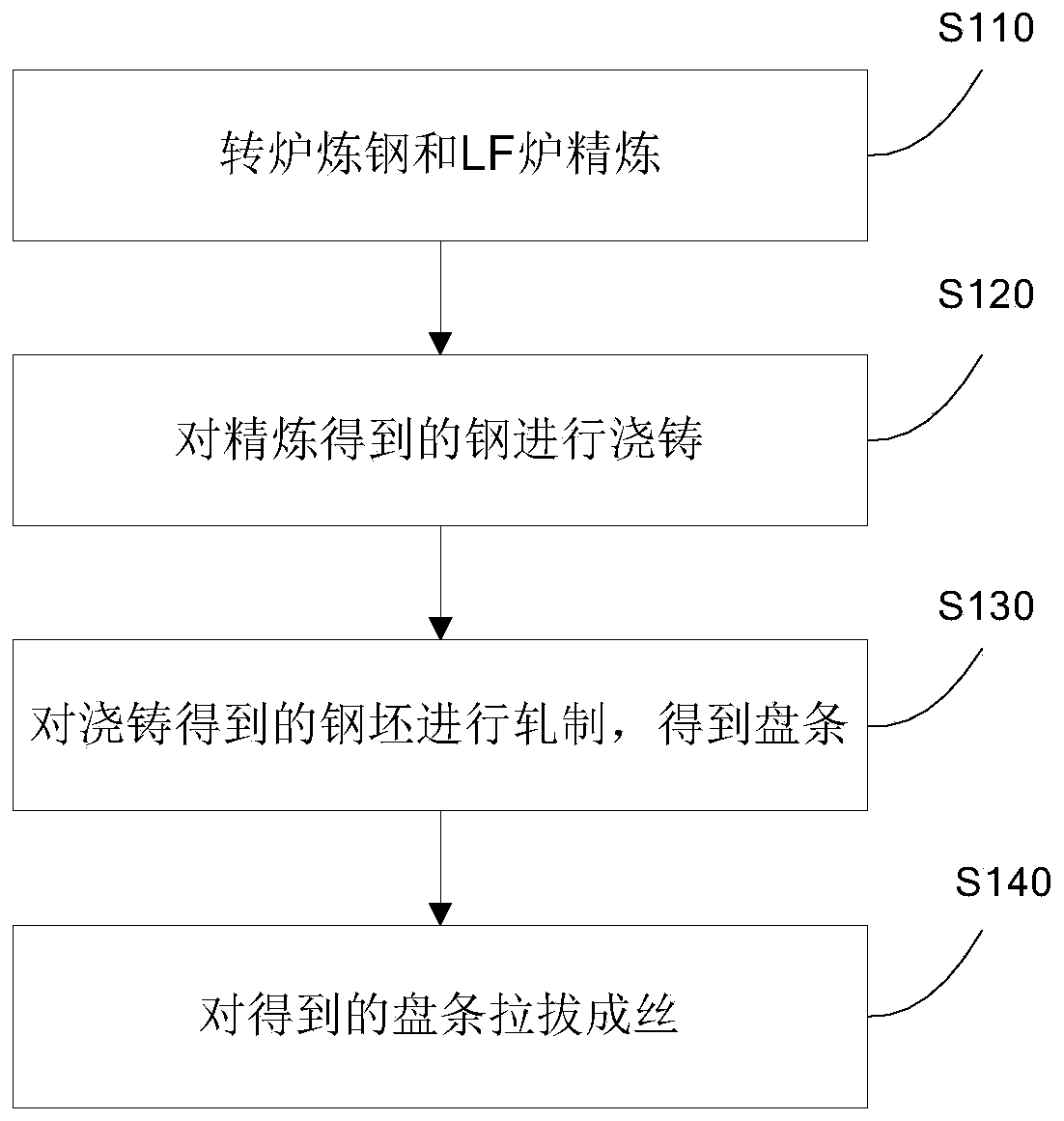

Method used

Image

Examples

Embodiment Construction

[0029] The embodiment of the present invention solves the technical problem in the prior art that high corrosion resistance to sulfuric acid and hydrochloric acid and low-temperature impact toughness cannot be achieved by providing a high impact toughness solid welding wire with acid corrosion resistance and a preparation method thereof.

[0030] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

[0031] The embodiment of the present invention adopts ultra-low carbon, reduces the carbon equivalent, thereby reducing the cold crack sensitivity of the weld metal, and at the same time helps to improve low-temperature impact toughness. At the same time, appropriate Si, Mn, Cu, and Cr contents can ensure the strength of the weld metal. A higher Ni content can improve the low temperature impact toughness of the weld metal. In addition, by adding a certain amount of Sb element, the corrosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com