A kind of graphene-silicon-based composite negative electrode material for lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as large-scale preparation of difficult materials, impact on material conductivity, and danger, and achieve structural stability and cycle performance. Improve conductivity and ensure continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

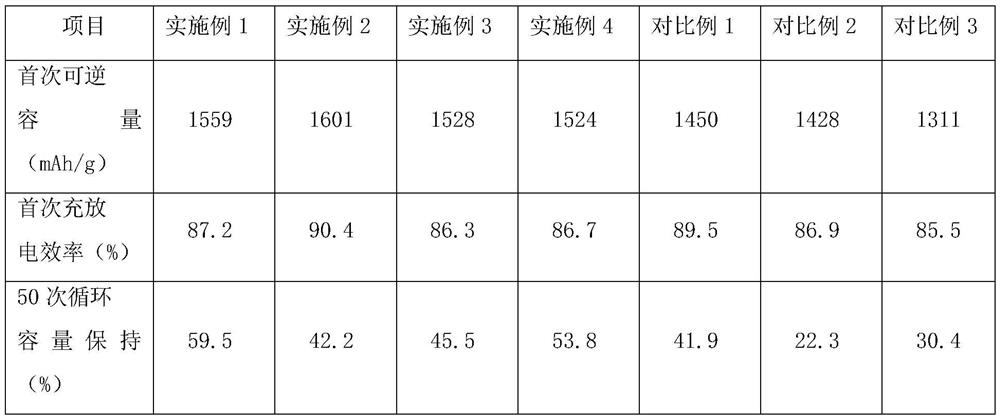

Examples

preparation example Construction

[0025] The preparation method of graphene-silicon-based composite negative electrode material for lithium ion battery of the present invention comprises the following steps:

[0026] Step 1, adding nano-silicon, graphene, and graphite into a ball mill tank according to a certain proportion and milling for a certain period of time to obtain uniformly mixed material 1;

[0027] Step 2: Add the material 1 and the organic carbon source into the organic solvent, stir and mix, and disperse evenly, then place in a water bath and heat to 70-90°C, heat and stir until the organic solvent evaporates to dryness, and then vacuum-dry at 60-100°C Overnight, material 2 was obtained.

[0028] Step 3: Extrude and granulate the obtained material 2 with a tablet machine, then heat to 150-300°C to maintain a constant temperature, and then heat up to 700-950°C for high-temperature carbonization after the organic carbon source is completely melted to obtain organic cracked carbon Coated graphene-si...

Embodiment 1

[0037] A preparation method of graphene-silicon-based composite negative electrode material of the present invention, comprises the following steps:

[0038] Nano-silicon, graphene, and artificial graphite with a particle size of less than 300nm and a particle size of about 5 μm are added to a ball mill tank according to a certain proportion and ball milled for 300 minutes. The ball-to-material ratio is 10:1, the speed is 500 rpm, and the solid content is 50%. Stir and mix with pitch in ethanol and disperse evenly for 2h afterwards (wherein pitch residual carbon rate is 41%, nano-silicon: graphene: graphite: pitch cracking carbon mass ratio is 45.5:4.5:25:25), in water bath, heat to 70 ℃, heated and stirred until the ethanol evaporated to dryness, and dried under vacuum at 60 ℃ overnight. The mixture is extruded and granulated with a tablet machine, heated to 200°C to maintain a constant temperature for 2 hours, and the heating rate is 5°C / min. After the asphalt is completely ...

Embodiment 2

[0041] A preparation method of graphene-silicon-based composite negative electrode material of the present invention, comprises the following steps:

[0042]Nano-silicon, graphene, and artificial graphite with a particle size of less than 300nm and a particle size of about 5 μm are added to a ball mill tank according to a certain proportion and milled for 180 minutes. The ball-to-material ratio is 6:1, the speed is 500 rpm, and the solid content is 50%. Stir and mix with pitch in ethanol and disperse evenly for 2h afterwards (wherein pitch residual carbon rate is 41%, nano-silicon: graphene: graphite: pitch cracking carbon mass ratio is 45.5:4.5:25:25), heated to 70 in water bath ℃, heated and stirred until the ethanol evaporated to dryness, and dried under vacuum at 60 ℃ overnight. The mixture is extruded and granulated with a tablet machine, heated to 200°C to maintain a constant temperature for 2 hours, and the heating rate is 5°C / min. After the asphalt is completely melted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com