Fabrication method of power amplifier antenna integrated PCB and power amplifier antenna integrated PCB

A manufacturing method and antenna technology, which are applied in the field of power amplifier-antenna integrated PCB and power amplifier-antenna integrated PCB manufacturing field, can solve the problems of poor fluidity of prepreg, high cost of sheet pressing, short circuit of electroplating copper infiltration, etc., and achieve the conditions of pressing and curing. The effect of easy control, lower production cost, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

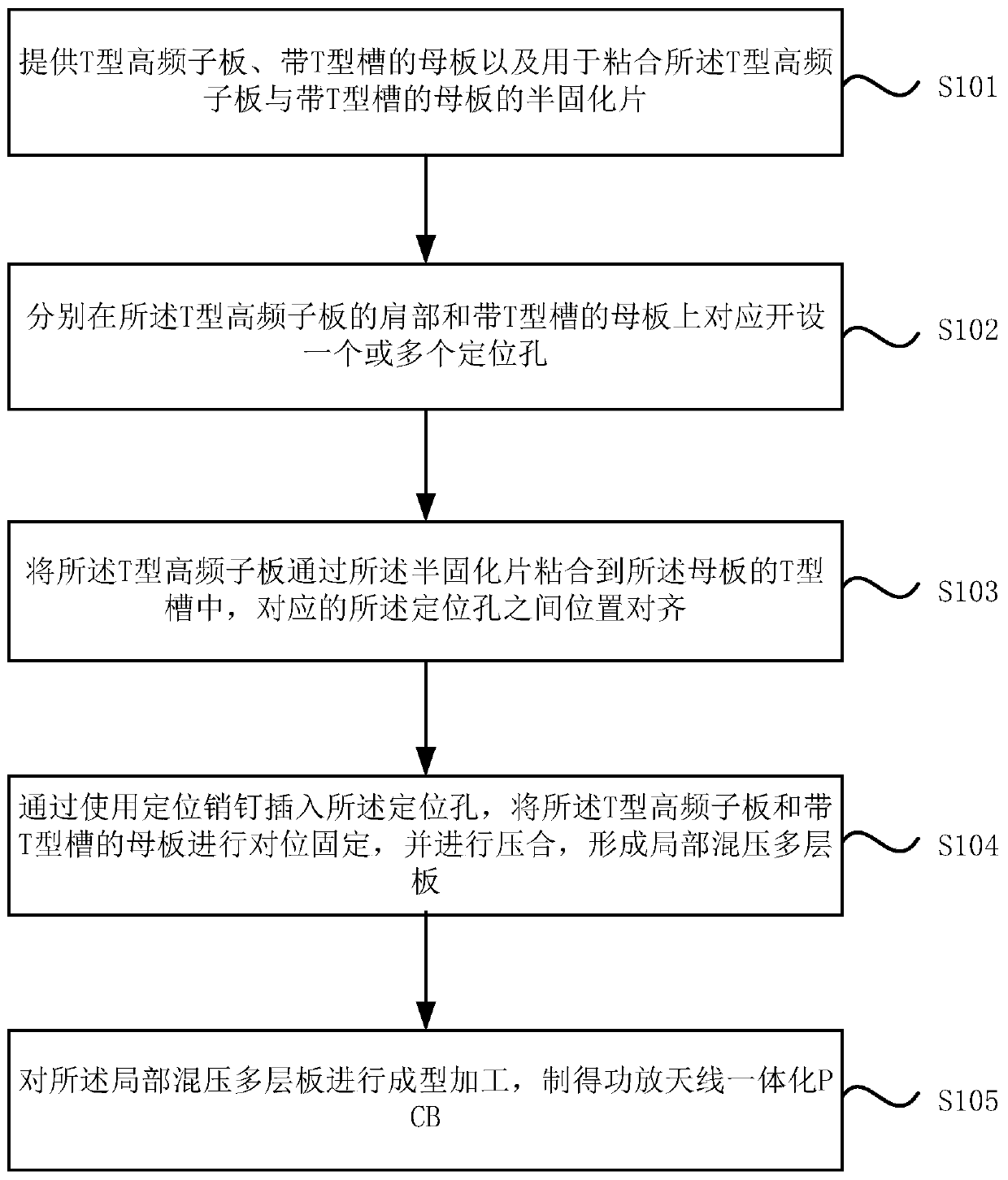

[0052] see figure 1 , the first embodiment provides a method for manufacturing a power amplifier antenna integrated PCB, including steps:

[0053] S101. Provide a T-shaped high-frequency sub-board, a motherboard with a T-shaped slot, and a prepreg for bonding the T-shaped high-frequency sub-board and the motherboard with a T-shaped slot.

[0054] Wherein, the shape of the T-shaped slot matches the shape of the T-shaped high-frequency sub-board.

[0055] Specifically, the step of providing the T-shaped high-frequency sub-board in step S101 further includes:

[0056] (1) providing a plurality of first core boards and prepregs, the material of the first core boards being the first material;

[0057] Wherein, the first material is a high-frequency plate with low loss and low dielectric constant, which can ensure low loss and high-quality transmission of antenna signals.

[0058] (2) Place the prepreg between every two first core boards and press them together to form the first-...

Embodiment 2

[0096] The second embodiment provides an integrated power amplifier and antenna PCB, which is manufactured according to the manufacturing method provided in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com