Conductive control device of fiber brush structure

A technology of control devices and fiber brushes, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of single copper wire wear, short service life, large contact wear, etc., achieve low contact wear rate, no lubricant, contact low pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

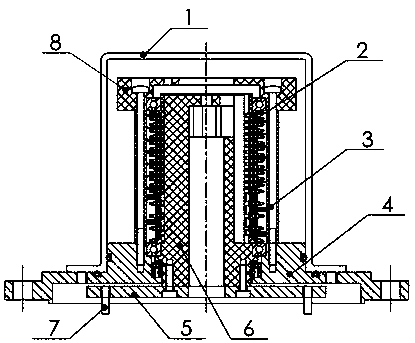

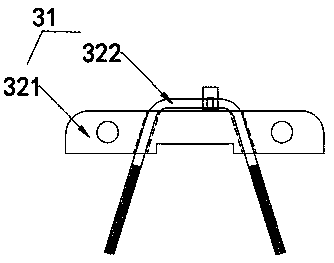

[0018] Depend on figure 1 It is known that a conductive control device with a fiber brush structure includes a central slip ring assembly 2, a base 4, a transmission disc 5, a support disc 6 and a transmission pin 7, and a circular boss is arranged in the middle of the base 4, and the circular A matching hole is provided in the middle of the boss; the central slip ring assembly 2 is fixed on the support disc 6, and the bottom end of the support disc 6 is fixed on the transmission disc 5 through the cooperation hole in the middle of the base 4, and the transmission disc 5 is also provided below There is a transmission pin shaft 7 that is threaded; it is characterized in that: the conductive control device also includes a fiber brush assembly 3, and the fiber brush assembly 3 is fixed on the circular boss of the base 4 by bolts, and the transmission pin shaft 7 will The power on the connecting device is transmitted to the transmission disc 5 to drive the central slip ring assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com