Diaphragm coating liquid, preparation method thereof, diaphragm, preparation method of diaphragm, and secondary battery

A production method and technology of coating liquid, applied in battery pack parts, circuits, electrical components and other directions, can solve the problems of low stability of the diaphragm, safety problems, high thermal shrinkage rate, etc., and achieve good thermal shrinkage performance, Improved performance and reduced thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

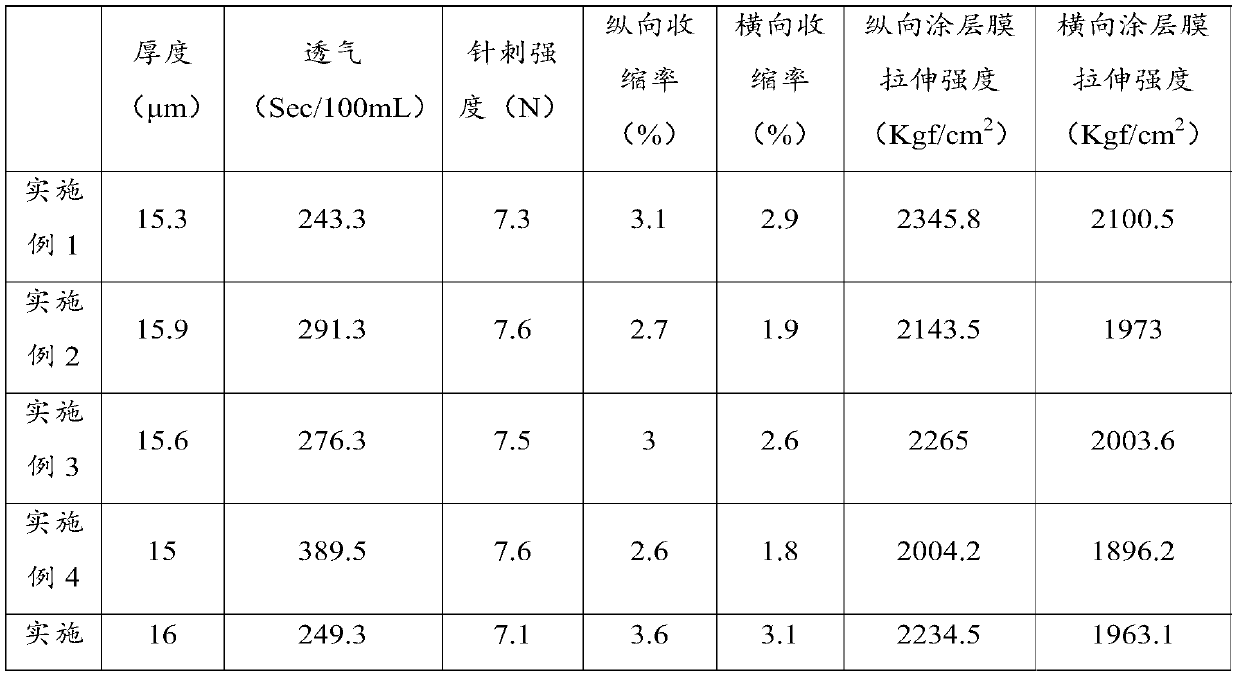

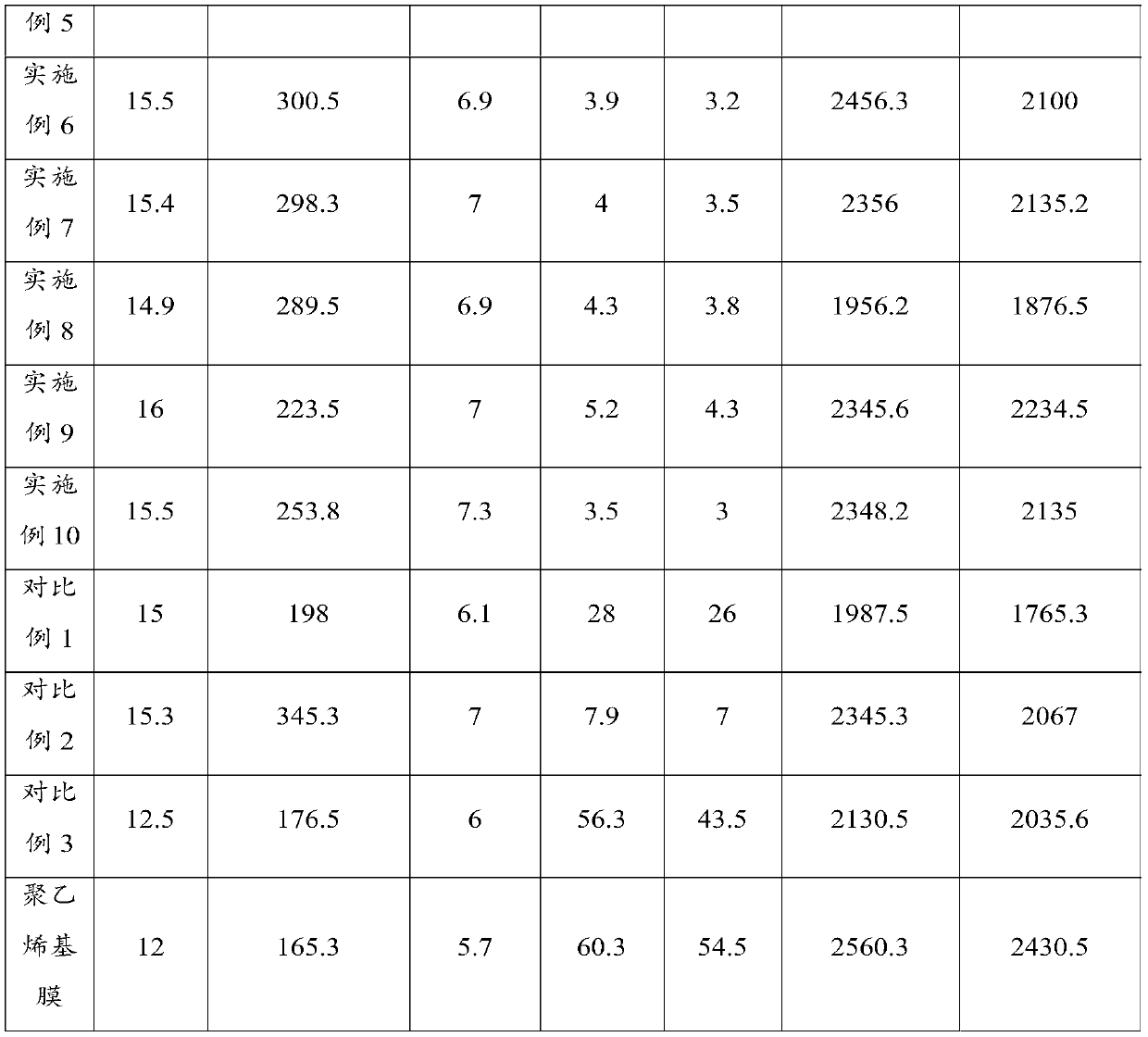

Examples

Embodiment 1

[0107] This embodiment provides a method for preparing a diaphragm coating solution, comprising the following steps:

[0108] (1) Dry 75g of polyetherimide at a temperature of 110°C for 3 hours, and then dissolve the dried polyetherimide in 1.92L of N-methylpyrrolidone at a temperature of 50°C to obtain Polyetherimide solution;

[0109](2) Add 30 g of polyvinylidene fluoride powder to the polyetherimide solution, stir until dissolved, then add 150 g of dimethyl carbonate, and stir until the precipitated polyetherimide is dissolved to obtain the first dispersion;

[0110] (3) Add 1.5g of vinyl bisstearamide to 300mL of N-methylpyrrolidone, stir evenly, then add 450g of alumina particles, and fully disperse to obtain the second dispersion;

[0111] (4) Mix the first dispersion liquid with the second dispersion liquid, stir until uniform to obtain a mixed liquid, then filter the mixed liquid (80-120 mesh sieve) and discharge to obtain a diaphragm coating liquid;

[0112] Wherei...

Embodiment 2

[0114] This embodiment provides a method for preparing a diaphragm coating solution, comprising the following steps:

[0115] (1) Dry 300g of polyetherimide at a temperature of 150°C for 2 hours, and then dissolve the dried polyetherimide in 600mL of dimethylacetamide at a temperature of 60°C to obtain a polyetherimide Ether imide solution;

[0116] (2) Add 90 g of polyvinylpyrrolidone powder into the polyetherimide solution, stir until dissolved, then add 450 mL of ethyl acetate, and stir until the precipitated polyetherimide is dissolved to obtain the first dispersion;

[0117] (3) Add 90g of oxidized polyethylene wax to 600mL of N-methylpyrrolidone, stir evenly, then add 900g of barium titanate particles, and fully disperse to obtain the second dispersion;

[0118] (4) Mix the first dispersion liquid with the second dispersion liquid, stir until uniform to obtain a mixed liquid, then filter the mixed liquid (80-120 mesh sieve) and discharge to obtain a diaphragm coating li...

Embodiment 3

[0121] This embodiment provides a method for preparing a diaphragm coating solution, comprising the following steps:

[0122] (1) Dry 240g of polyetherimide at a temperature of 130°C for 4 hours, and then dissolve the dried polyetherimide in 1.4L of dimethylacetamide at a temperature of 80°C to obtain Polyetherimide solution;

[0123] (2) Add 60 g of polyvinyl alcohol powder to the polyetherimide solution, stir until dissolved, then add 300 g of dimethyl phosphate, and stir until the precipitated polyetherimide is dissolved to obtain the first dispersion;

[0124] (3) Add 30g of vinylbisstearamide to 400mL of dimethyl phthalate, stir evenly, then add 600g of silica particles, and fully disperse to obtain the second dispersion;

[0125] (4) Mix the first dispersion liquid with the second dispersion liquid, stir until uniform to obtain a mixed liquid, then filter the mixed liquid (80-120 mesh sieve) and discharge to obtain a diaphragm coating liquid;

[0126] Among them, the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com