Biologic solar cell having three-layer chlorophyll structure and preparation method thereof

A solar cell and chlorophyll technology, applied in photovoltaic power generation, photosensitive equipment and other directions, can solve problems such as limiting cell efficiency and limited charge extraction capability, and achieve the effects of simple synthesis route, improved carrier mobility, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

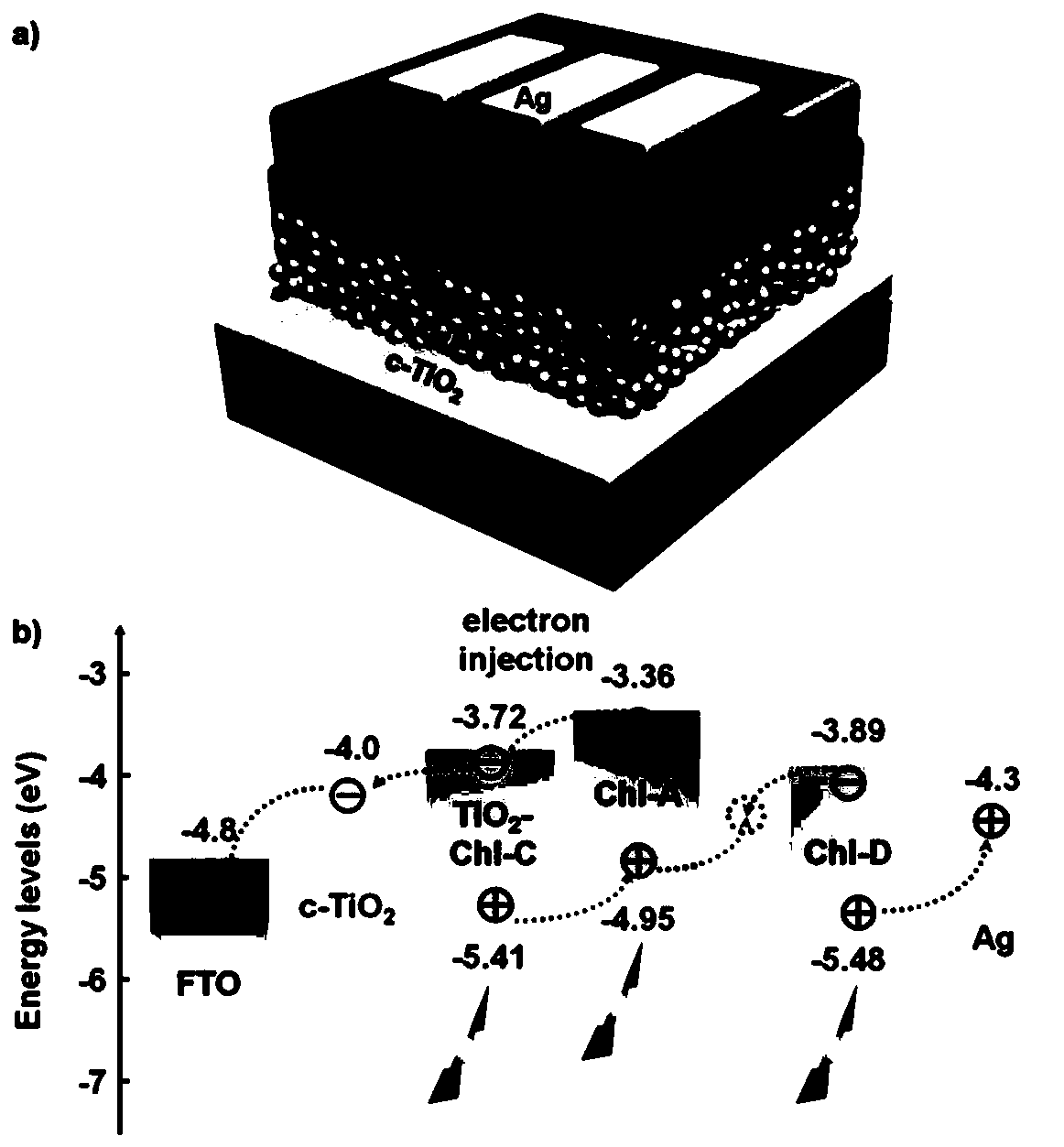

[0068] The invention provides a method for preparing a biological solar cell with a three-layer chlorophyll structure, which specifically includes the following steps:

[0069] 1) Treatment of transparent conductive glass cathode:

[0070] Treat the cleaned transparent conductive glass with ozone for 30 minutes;

[0071] 2) Preparation of electron transport layer:

[0072] Place the transparent conductive glass treated in step 1) on a homogenizer to spin-coat the electron transport layer. The spin-coating process is 4500rpm / min and rotate for 30s to form a layer of titanium oxide precursor film, and then immediately place it on the hot stage for annealing treatment, the annealing temperature and time are 200°C for 30 minutes;

[0073] 3) Preparation of dye-sensitized mesoporous semiconductor layer:

[0074] Spin-coat the mesoporous semiconductor layer on the conductive substrate that has been annealed and lowered to room temperature on a homogenizer. The spin-coating proces...

Embodiment 1

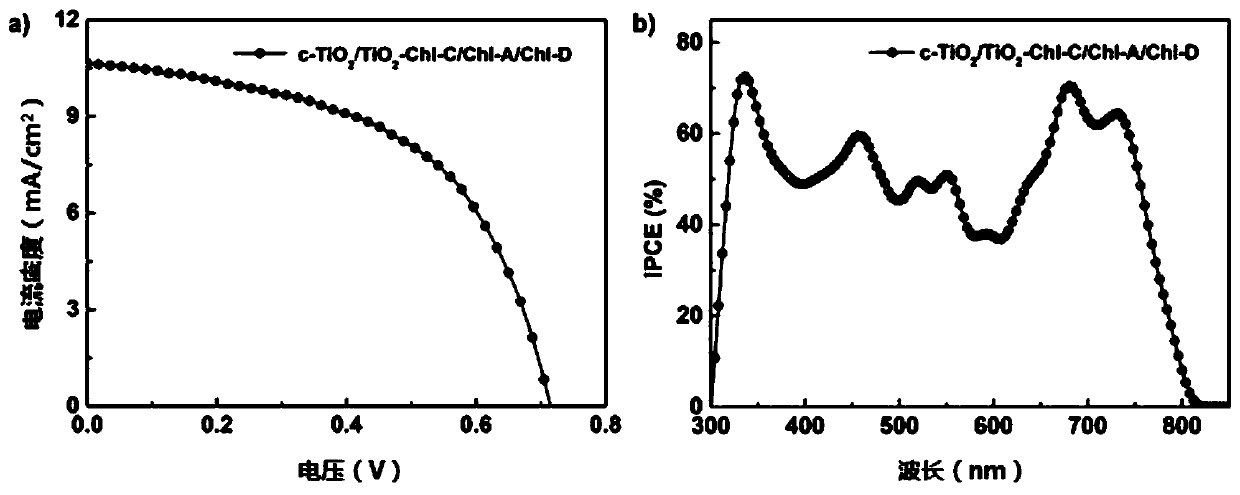

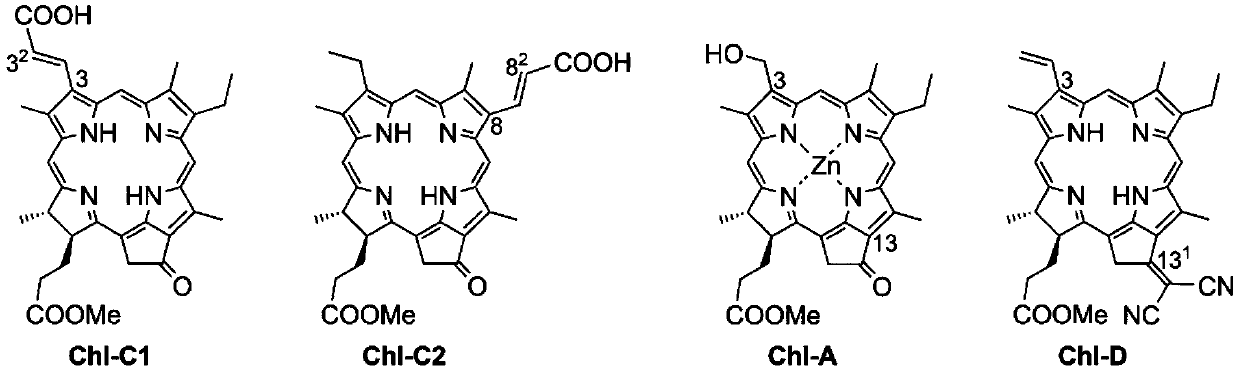

[0090] The FTO etched on the transparent substrate was ultrasonically treated twice for 30 minutes with cleaning agent, deionized water, alcohol, acetone, and isopropanol, and then prepared TiO 2 For the precursor solution, 100 μL of isopropyl titanate was dissolved in 1 mL of absolute ethanol containing 10 μL of hydrochloric acid, and stirred at room temperature for 5 minutes before use. Dissolve 1.97 mg of titanium dioxide nanoparticles (PST-18NR) in 1 mL of absolute ethanol and stir overnight at room temperature to obtain mesoporous TiO 2 solution. 40 μL of titanium tetrachloride solution (1.5 g / mL) was dissolved in 10 mL of deionized water, and stirred at room temperature for 5 minutes. 0.99mg Chl-C1 and 0.01mg Chl-C2 chlorophyll dyes were dissolved in 10mL absolute ethanol, and stirred at room temperature in the dark until dissolved. In a glove box, dissolve Chl-A in tetrahydrofuran and chloroform (4:1 volume ratio), stir at room temperature until dissolved, and prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com