Composite copper anode mold capable of prolonging service life and production method thereof

A composite, copper anode technology, applied in the improvement of process efficiency, electrodes, photography technology and other directions, can solve the problems of restricting the smelting production efficiency of copper smelters and the low service life of copper anode molds, and achieves slowing down the probability of early bursting, high Mechanical strength and thermal fatigue resistance, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

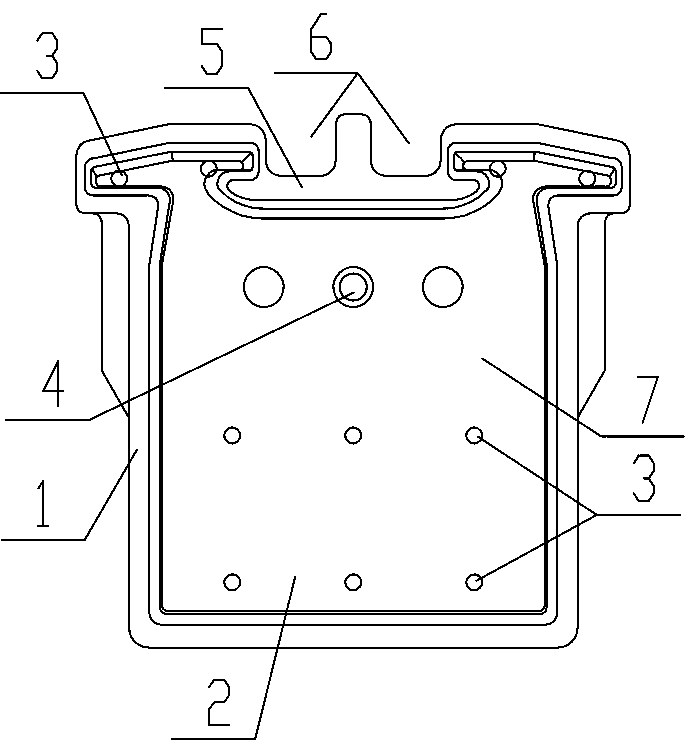

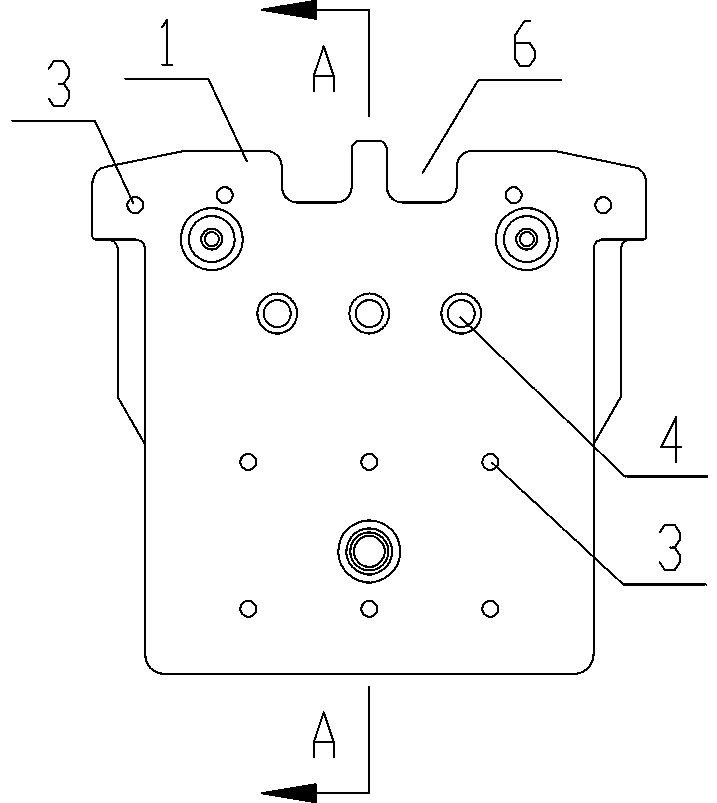

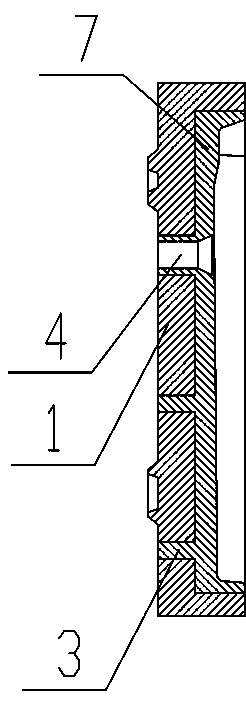

[0021] see Figure 1-3 , the present embodiment includes a mold body, the mold body is provided with a copper pouring cavity, and the mold body is located at the upper part of the copper pouring cavity and is provided with a top mold hole for lifting the mold, and the mold body is also provided with several holes in the copper pouring cavity. Anchor hole, a layer of chromium-zirconium-copper alloy is fixed through the anchor hole in the copper-casting cavity, and the chemical composition weight percentage of the chromium-zirconium-copper alloy is: Cr:0.75, Zr:0.15, Mn<0.0013, Mo<0.0003, Ni <0.0005, Fe<0.037, the balance is Cu.

[0022] The middle section of the top of the phantom described in this embodiment is provided with two symmetrically arranged grooves, forming a mountain-shaped surrounding structure.

[0023] In this embodiment, there are at least four anchor holes, forming a rectangle.

[0024] The material of the mold body described in this embodiment is ductile ir...

Embodiment 2

[0027] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the chemical composition weight percentage of the chromium-zirconium-copper alloy is: Cr: 0.85, Zr: 0.25, Mn<0.0013, Mo<0.0003, Ni<0.0005, Fe<0.037 , the balance being Cu.

Embodiment 3

[0029] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the chemical composition weight percentage of the chromium-zirconium-copper alloy is: Cr:0.8, Zr:0.2, Mn<0.0013, Mo<0.0003, Ni<0.0005, Fe<0.037 , the balance being Cu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com