Thermal treatment method for civil bulletproof steel

A heat treatment method and bulletproof steel technology, which is applied in the field of heat treatment of steel materials, can solve the problems of low toughness and high strength, and achieve the effects of improving toughness, improving impact toughness, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

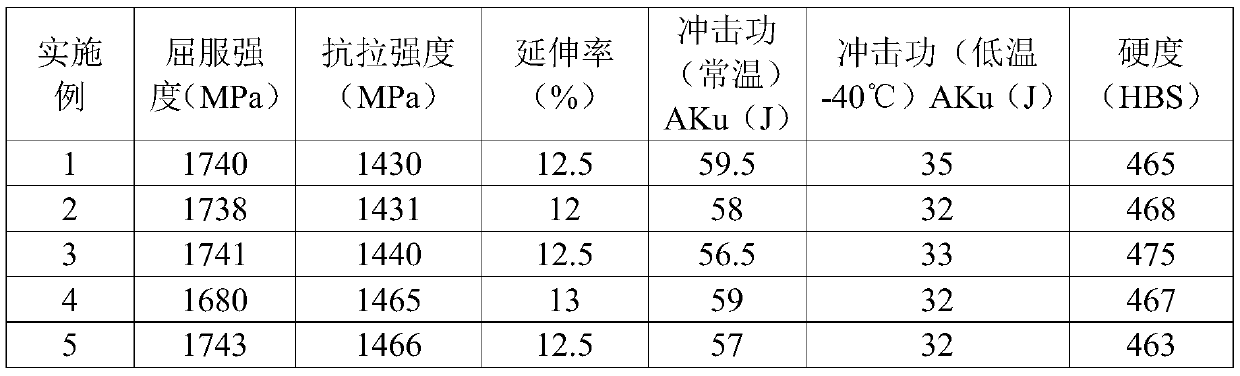

Examples

Embodiment 1

[0024] (1) Quenching: Heat the billet to 875°C at a heating rate of 10°C / min, keep it warm for 1.5h and then cool it to room temperature with oil.

[0025] (2) Quenching in the two-phase zone: heat to 750°C with a heating rate of 10°C / min and hold for 1 hour, then cool the oil to room temperature.

[0026] (3) Tempering: reheat the billet in (2) to 175°C, keep it warm for 3 hours, and then air-cool to room temperature.

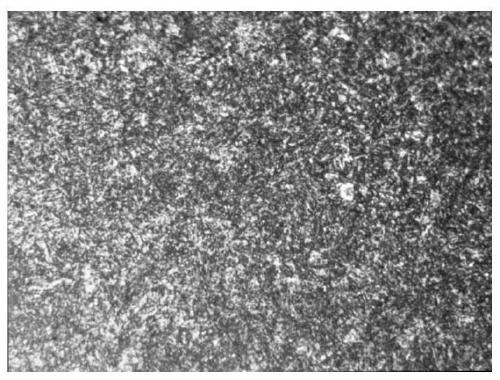

[0027] After the above heat treatment, the structure of the steel plate is ferrite + martensite, the performance test results are all within the design range, and the ballistic performance reaches the "box or bulletproof steel plate" C in the public safety industry standard GA 164-2005 of the People's Republic of China class.

Embodiment 2

[0029] (1) Quenching: Heat the steel billet to 885°C with a heating rate of 12°C / min, keep it warm for 1.5h and then cool it to room temperature with oil.

[0030] (2) Quenching in the two-phase zone: heat to 760°C with a heating rate of 10°C / min and hold for 1 hour, then cool the oil to room temperature.

[0031] (3) Tempering: reheat the billet in (2) to 180°C, keep it warm for 3 hours, and then air-cool to room temperature.

[0032] After the above heat treatment, the structure of the steel plate is ferrite + martensite, the performance test results are all within the design range, and the ballistic performance reaches the "box or bulletproof steel plate" C in the public safety industry standard GA 164-2005 of the People's Republic of China class.

Embodiment 3

[0034] (1) Quenching: Heat the steel billet to 895°C with a heating rate of 10°C / min, keep it warm for 1.6h and then cool it to room temperature with oil.

[0035] (2) Quenching in the two-phase zone: heat to 765°C with a heating rate of 12°C / min and hold for 1.2h, then cool the oil to room temperature.

[0036] (3) Tempering: reheat the billet in (2) to 190°C, keep it warm for 3 hours, and then air-cool to room temperature.

[0037] After the above heat treatment, the structure of the steel plate is ferrite + martensite, the performance test results are all within the design range, and the ballistic performance reaches the "box or bulletproof steel plate" C in the public safety industry standard GA 164-2005 of the People's Republic of China class.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com