A kind of degradable polyurethane biological material and its preparation method and application

A biomaterial and polyurethane technology, applied in the field of degradable polyurethane biomaterials and their preparation, can solve the problems of poor biomedical properties, physical and chemical properties of medical device products, and reduce the risk of inflammation, small pH changes, and effectiveness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

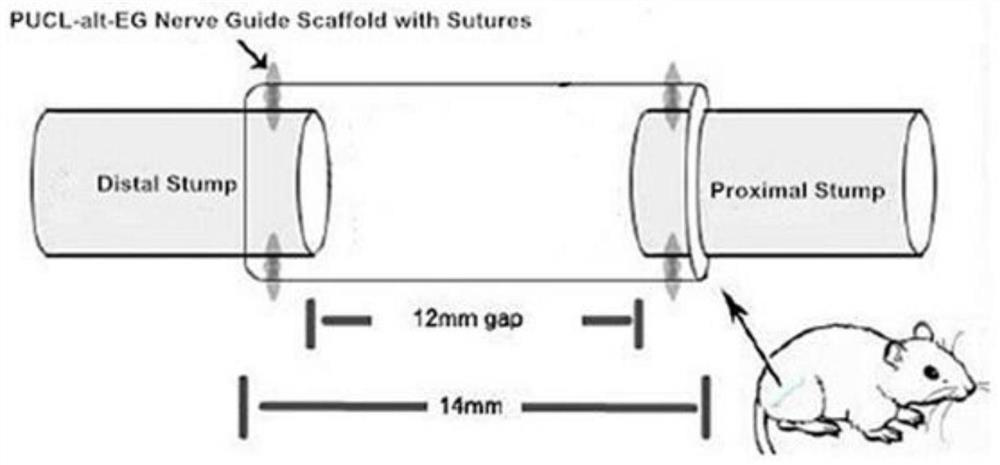

Image

Examples

Embodiment 1

[0045] Alternating block polyurethanes are prepared by the method of the present invention.

[0046] (1) Aliphatic polyether diol, the raw material of the second polymer, model is: polyether N-210 (molecular weight is 1000, purchased from Nanjing Xinyuan Chemical Co., Ltd.), ethylene glycol, propylene glycol, 1,4 -Butanediol is added in chloroform according to the mass ratio of 1:1:1:1, stirred and dissolved completely to obtain solution I; at this time, the mass ratio of aliphatic polyether diol to aliphatic diol is 1:3, The mass ratio of ethylene glycol, propylene glycol, and 1,4-butanediol in the aliphatic dihydric alcohol is 1:1:1;

[0047] (2) In the three-necked flask, the raw material diisocyanate of the first polymer is obtained by end-capping reaction to obtain the aliphatic polyester diol terminated by diisocyanate; wherein the diisocyanate is hexamethylene diisocyanate, and the aliphatic polyester diol The model is Oxyester T1136, Evonik (for linear polyester diol,...

Embodiment 2

[0051] By using the method of the present invention, the alternating block polyurethane prepared by using the mixture in the second polymer as a proportion outside the preferred range of the present invention.

[0052] (1) Aliphatic polyether diol, the raw material of the second polymer, is: polyether N-210, ethylene glycol, propylene glycol, and 1,4-butanediol in a mass ratio of 1:10:10: 10 was added to chloroform, stirred and dissolved completely to obtain solution I; at this time, the mass ratio of aliphatic polyether diol to aliphatic diol was 1:30, and in aliphatic diol, ethylene glycol, propylene glycol, 1, The mass ratio of 4-butanediol is 1:1:1;

[0053] (2) In a three-necked flask, utilize end-capping reaction (reaction conditions are the same as Example 1) to obtain the raw material diisocyanate end-blocked aliphatic polyester diol of the first polymer; wherein diisocyanate is hexamethylene diisocyanate , the aliphatic polyester diol model is Oxyester T1136, Evonik;...

Embodiment 3

[0056] By using the method of the present invention, the alternating block polyurethane prepared by using the mixture in the second polymer as a proportion outside the preferred range of the present invention.

[0057] (1) Aliphatic polyether diol, the raw material of the second polymer, is: polyether N-210, ethylene glycol, propylene glycol, and 1,4-butanediol in a mass ratio of 1:1:15: 15 was added into chloroform, stirred and dissolved completely to obtain solution I; at this time, the mass ratio of aliphatic polyether diol to aliphatic diol was 1:31, and in aliphatic diol, ethylene glycol, propylene glycol, 1, The mass ratio of 4-butanediol is 1:15:15;

[0058] (2) In a three-necked flask, utilize end-capping reaction (reaction conditions are the same as Example 1) to obtain the raw material diisocyanate end-blocked aliphatic polyester diol of the first polymer; wherein diisocyanate is hexamethylene diisocyanate , the aliphatic polyester diol model is Oxyester T1136, Evon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com