Preparation method of poly(ether-ether-ketone) resin containing ferrocene/DOPO group and crosslinked alkenyl

A technology of alkenyl polyether and ferrocene is applied in the field of preparation of resin containing ferrocene/DOPO group and cross-linked alkenyl polyether ether ketone, which can solve the problem of many additives, reducing cable reliability and increasing product cost etc., to achieve the effect of high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

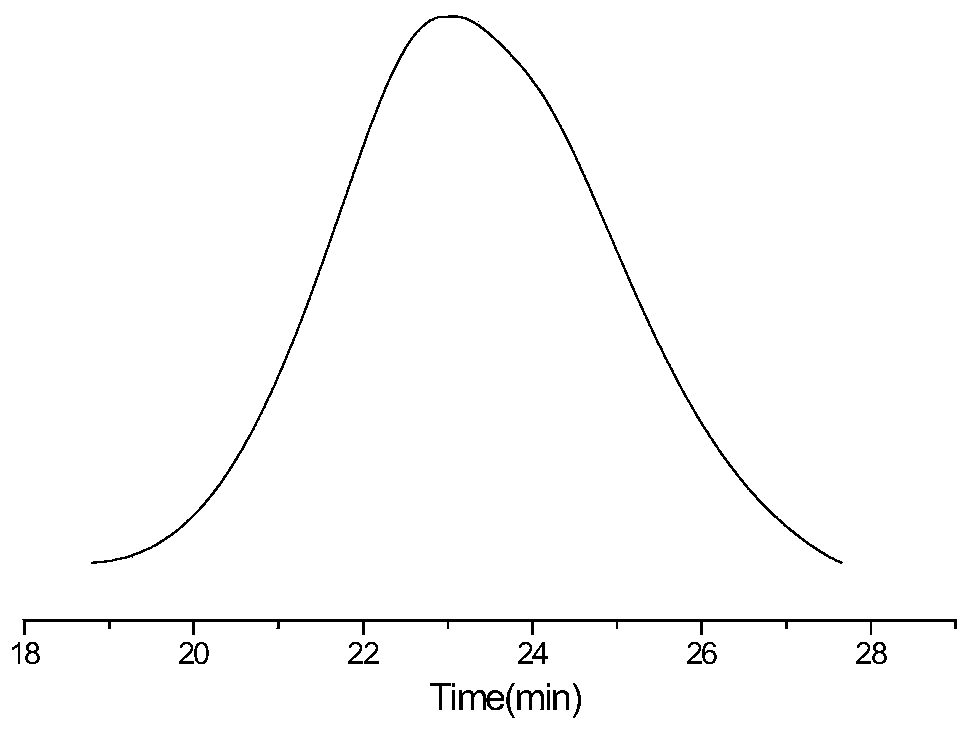

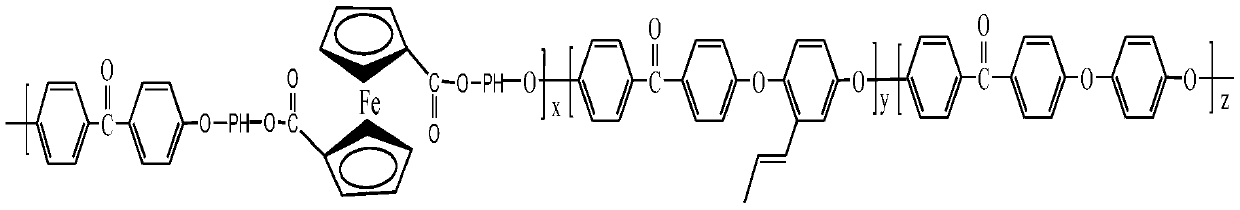

Image

Examples

Embodiment 1

[0040] (1) Synthesis of ferrocene and DOPO-based bisphenol monomers: 6.4854 g of DOPO-based bisphenol (I), 2.7405 g of 1,1'-ferrocenedicarboxylic acid, and 4-bisphenol Add 2.4534g of methylaminopyridine and 140mL of dichloromethane, put it into an ice bath and stir and fill with N 2 After 30 minutes, dissolve 4.166g of N,N'-dicyclohexylcarboimide in 20mL of dichloromethane, add dropwise to the above solution within 60 minutes, naturally warm to room temperature under stirring and continue to react for 24 hours, and concentrate the reaction solution , cooling, filtering, washing, and drying, and drying the precipitate in a vacuum oven at 40° C. for 10 h to obtain a product containing ferrocene and DOPO-based bisphenol (M1) monomer.

[0041] (2) Synthesis of polyether ether ketone containing ferrocene, DOPO group and cross-linked alkenyl group: In a three-necked flask, 1.1186 g (2 mmol) of bisphenol (M1) containing ferrocene and DOPO group, and 3.6512 bisphenol A g (16mmol), 3....

Embodiment 2

[0046] (1) Synthesis of monomers containing ferrocene and DOPO-based bisphenol (M2): Add 7.4840 g of DOPO-based bisphenol (II), 2.2261 g of triethylamine and 120 mL of dichloromethane in a three-necked flask, and stir to dissolve Evenly, 2.9305g of 1,1'-ferrocenedicarboxylic acid chloride was dissolved in 20mL of dichloromethane, slowly dripped into the above solution under stirring, reacted at room temperature for 24h, raised the temperature to 42-45°C, reacted for 8h, and evaporated the solvent , cooled, filtered, washed and dried, and the precipitate was dried in a vacuum oven at 40° C. for 10 h to obtain a product containing ferrocene and DOPO-based bisphenol (M2) monomer.

[0047] (2) Synthesis of polyether ether ketone containing ferrocene, DOPO group and cross-linked alkenyl: In a three-necked flask, 2.4493 g (4 mmol) of bisphenol (M2) containing ferrocene and DOPO group, hydroquinone 1.6515g (15mmol), 4.1458g (19mmol) of difluorobenzophenone, 4.1463g (30mmol) of anhydr...

Embodiment 3

[0050] (1) Synthesis of bisphenol containing ferrocene and DOPO-based monomers: Add 6.4854 g of DOPO-based bisphenol (I), 2.2261 g of triethylamine and 120 mL of dichloromethane in a three-necked flask, stir and dissolve evenly, 2.9305 Dissolve g1,1'-ferrocenedicarboxylic acid chloride in 20mL of dichloromethane, slowly drop into the above solution under stirring, react at room temperature for 24h, raise the temperature to 42-45°C, react for 8h, evaporate the solvent, cool and filter , washing and drying to obtain a product containing ferrocene and DOPO-based bisphenol (M1) monomers.

[0051] (2) Synthesis of polyetheretherketone containing ferrocene, DOPO group and crosslinked alkenyl group: 5.5929g (10mmol) of bisphenol (M1) containing ferrocene and DOPO group, hexafluorobisphenol A3.3623g (10mmol), difluorobenzophenone 4.3640g (20mmol), anhydrous potassium carbonate 6.2195g (45mmol), toluene 80mL, DMAc100mL, in 1mL / sec N 2 React at 140°C for 3 hours, then raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com