A kind of preparation method of bisphenol monomer containing phthalazinone structure

A technology of phthalazinone and monomers, which is applied in the field of preparation of bisphenol monomers containing phthalazinone structures, can solve problems such as poor solubility, and achieve the effects of mild reaction, reduced synthesis cost, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

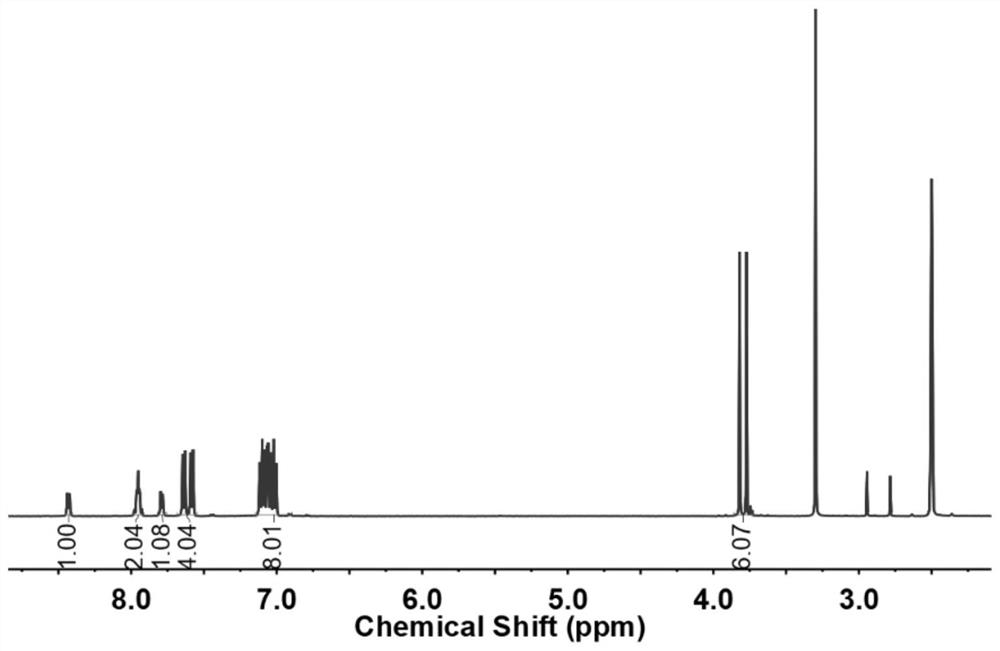

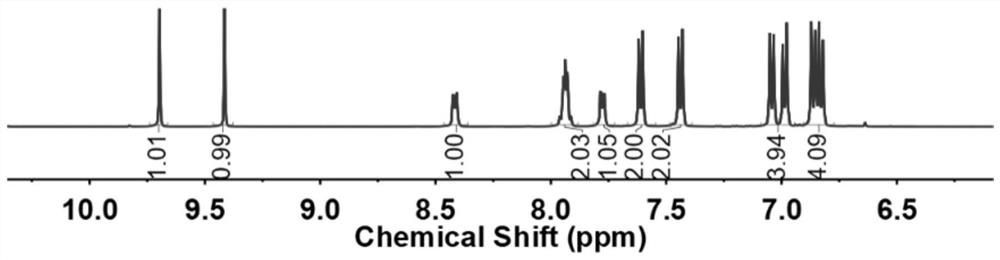

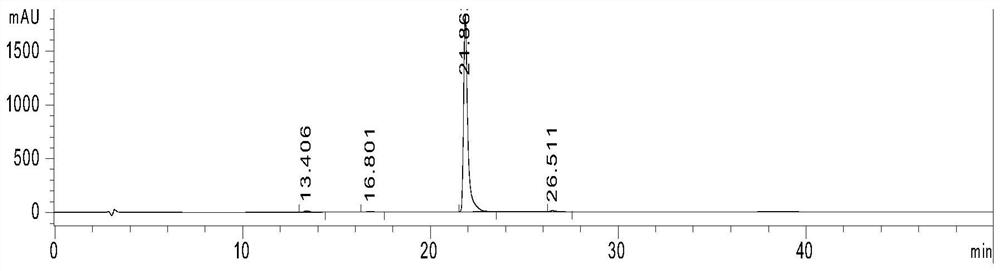

[0018] Embodiment 1: add DHPZ and K to the there-necked flask equipped with magnetic stirring, reflux condensing device 2 CO 3 , at 135 ° C for 5-6 hours of salt formation reaction, after the salt formation reaction is over, the reaction solution is lowered to room temperature, then Ullman coupling ligand PNTM, catalyst CuI and reactant BPM are added, and the reaction is protected from light for 12 hours. The temperature was gradually raised from room temperature to 130°C. After the reaction is completed, the reaction solution is immersed in hot water, drained overnight, the brown solid is dissolved in chloroform, the filtrate obtained by suction filtration is added with excess anhydrous sodium sulfate to remove water, and the brown powdery solid is obtained after rotary evaporation, using acetone or ethanol. Rinse 1-2 times to obtain a light yellow solid, which is vacuum dried in a vacuum drying oven at 100°C for 10-12 hours. Refined with DMAc at a mass-volume ratio of 1:2....

Embodiment 2

[0019] Embodiment 2: add DHPZ and K to the there-necked flask equipped with magnetic stirring, reflux condensing device 2 CO 3 , at 135 ℃ for 5-6 hours of salt formation reaction, after the salt formation reaction is over, the reaction solution is lowered to room temperature, then Ullman coupling ligand PNTM, catalyst CuI and reactant BPM are added, and the reaction is protected from light for 18 hours. The temperature was gradually raised from room temperature to 130°C. After the reaction is completed, the reaction solution is immersed in hot water, drained overnight, the brown solid is dissolved in chloroform, the filtrate obtained by suction filtration is added with excess anhydrous sodium sulfate to remove water, and the brown powdery solid is obtained after rotary evaporation, using acetone or ethanol. Rinse 1-2 times to obtain a light yellow solid, which is vacuum dried in a vacuum drying oven at 100°C for 10-12 hours. Refined with DMAc at a mass-volume ratio of 1:2.5 ...

Embodiment 3

[0020] Embodiment 3: add DHPZ and K to the there-necked flask equipped with magnetic stirring, reflux condensing device 2 CO 3 , at 135 ℃ for 5-6 hours of salt formation reaction, after the salt formation reaction is over, the reaction solution is lowered to room temperature, then Ullman coupling ligand PNTM, catalyst CuI and reactant BPM are added, and the reaction is darkened for 24 hours. The temperature was gradually raised from room temperature to 130°C. After the reaction is completed, the reaction solution is immersed in hot water, drained overnight, the brown solid is dissolved in chloroform, the filtrate obtained by suction filtration is added with excess anhydrous sodium sulfate to remove water, and the brown powdery solid is obtained after rotary evaporation, using acetone or ethanol. Rinse 1-2 times to obtain a light yellow solid, which is vacuum dried in a vacuum drying oven at 100°C for 10-12 hours. Refined with DMAc at a mass-volume ratio of 1:2.5 to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com