A kind of alloy solder suitable for 34crni3mo rotor parts

A technology of alloy brazing material and parts, which is applied in metal processing equipment, welding/cutting media/materials, welding equipment, etc., can solve the problems of high manufacturing cost and high price, and achieve improved liquid fluidity and gap filling performance , high electrical and thermal conductivity, self-strength and high-temperature performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

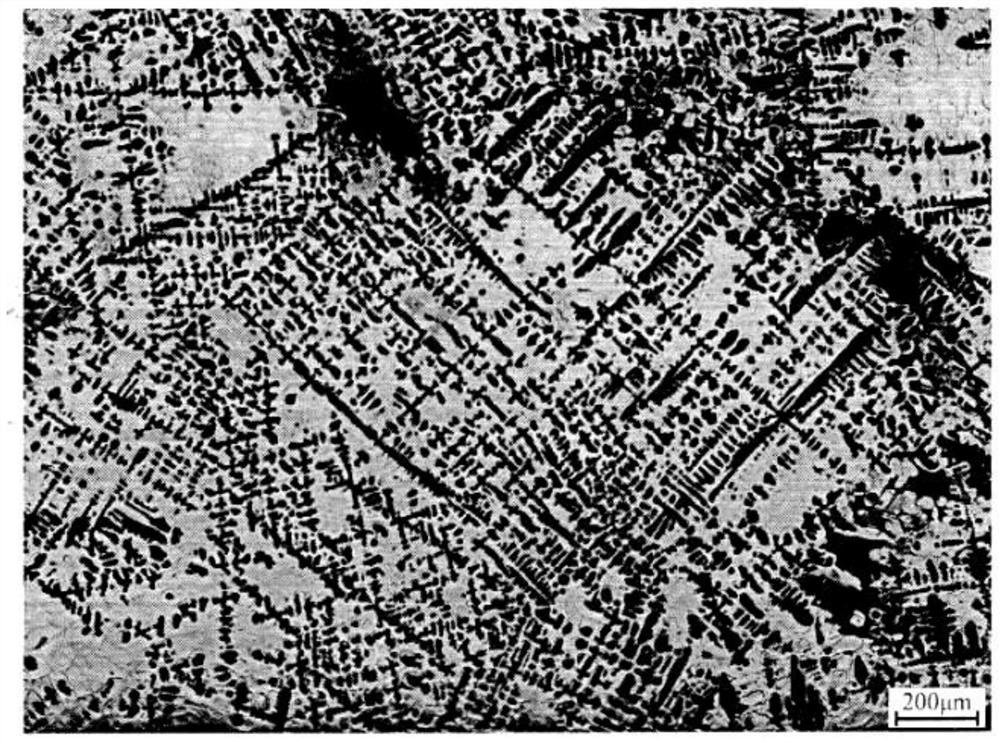

Image

Examples

Embodiment 1

[0033] This embodiment provides a kind of alloy solder suitable for 34CrNi3Mo rotor parts, by mass percentage, said alloy solder comprises:

[0034] 30% Mn;

[0035] 10% Co;

[0036] 5.8% Ni;

[0037] and the balance of Cu.

[0038] The alloy solder described in the present embodiment is obtained by the following steps: 1. The alloy components are smelted into an alloy according to the following composition ratio: Mn: 30%, Co: 10%, Ni: 5.8%, Cu: balance;

[0039] 2. It is prepared into powder particles or rolled into foil by gas atomization method.

[0040] It should be noted that there is no prior art for preparing the alloy into powder form or rolling the alloy into foil form by gas atomization method, which will not be repeated in this embodiment.

[0041] In order to verify the performance of the alloy solder, the present embodiment prepares the tensile test bar with the above-mentioned alloy solder, and detects that the tensile strength of the solder itself is 956MPa,...

Embodiment 2

[0046] This embodiment provides a kind of alloy solder suitable for 34CrNi3Mo rotor parts, by mass percentage, said alloy solder comprises:

[0047] 30% Mn;

[0048] 10% Co;

[0049] 6% Ni;

[0050] and the balance of Cu.

[0051] Alloy solder described in the present embodiment is obtained according to the following steps:

[0052] 1. The alloy components are smelted into alloys according to the following composition ratio: Mn: 30%, Co: 10%, Ni: 6%, Cu: balance;

[0053] 2. It is prepared into powder particles or rolled into foil by gas atomization method.

[0054] In this embodiment, the alloy solder of the above ratio is prepared into a tensile test rod, and it is detected that the tensile strength of the solder itself is 960MPa, which is higher than the strength value of 34CrNi3Mo, and the welding tensile strength is 852MPa, which meets the brazing requirements of 34CrNi3Mo parts. The alloy solder has a melting point of 929-966°C and a density of 8.685g / cm 3 , Vicker...

Embodiment 3

[0056] This embodiment provides a kind of alloy solder suitable for 34CrNi3Mo rotor parts, by mass percentage, said alloy solder comprises:

[0057] 30% Mn;

[0058] 10% Co;

[0059] 6.1% Ni;

[0060] and the balance of Cu.

[0061] Alloy solder described in the present embodiment is obtained according to the following steps:

[0062] 1. The alloy components are smelted into alloys according to the following composition ratio: Mn: 30%, Co: 10%, Ni: 6.1%, Cu: the balance;

[0063] 2. It is prepared into powder particles or rolled into foil by gas atomization method.

[0064] In this embodiment, the alloy solder of the above proportioning ratio is prepared into a tensile test rod, and it is detected that the tensile strength of the solder itself is 985MPa, which is higher than the strength value of 34CrNi3Mo, and the welding tensile strength is 886MPa, which meets the brazing requirements of 34CrNi3Mo parts. The alloy solder has a melting point of 934-982°C and a density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com