A5B19 type rare earth-yttrium-nickel system hydrogen storage alloy added with zirconium and titanium elements

A technology of hydrogen storage alloys and rare earths, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of increased manufacturing difficulty, difficult control of alloy components, and potential safety hazards, and achieves simple, safe, and The effect of good activation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

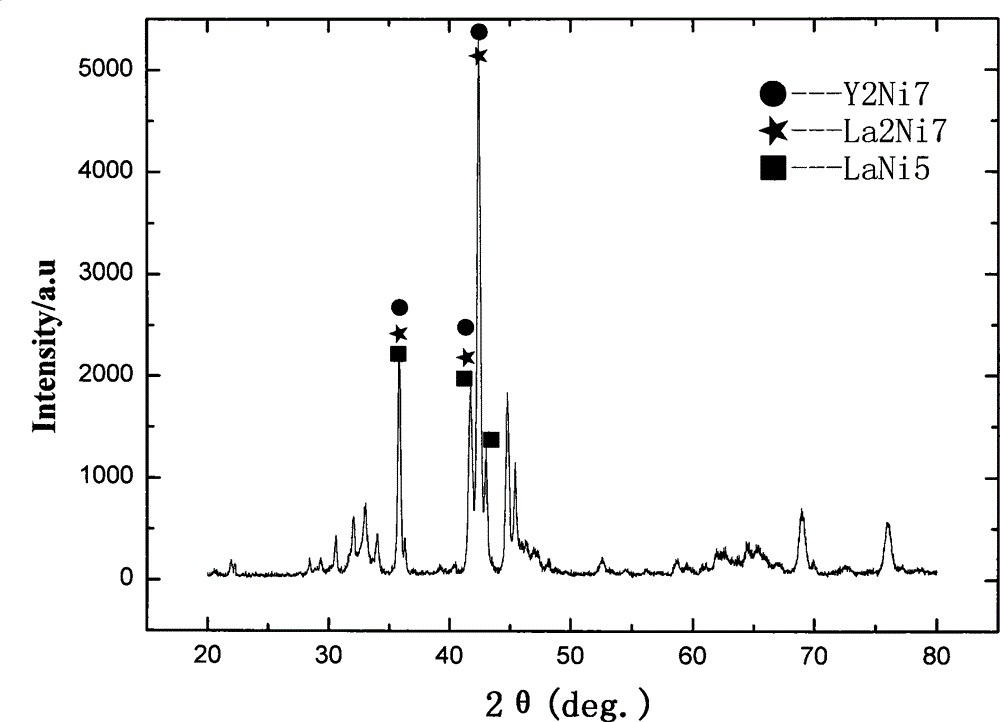

Image

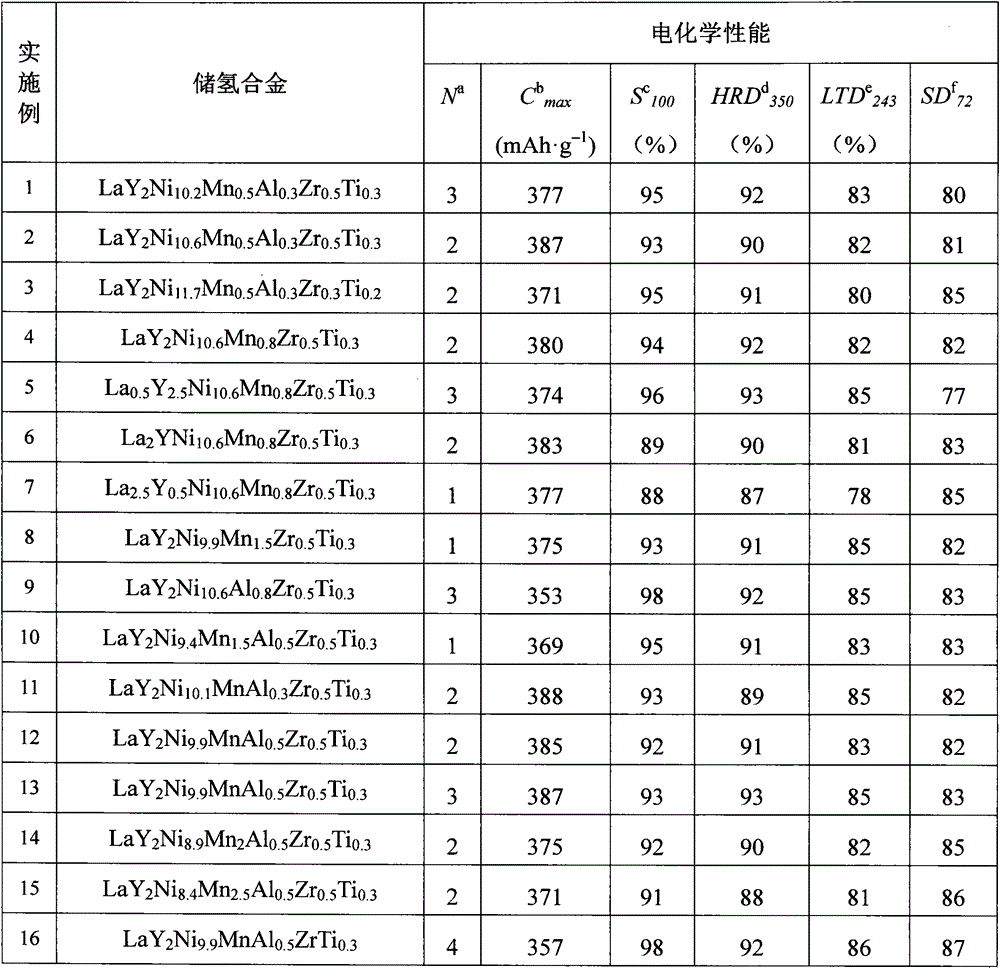

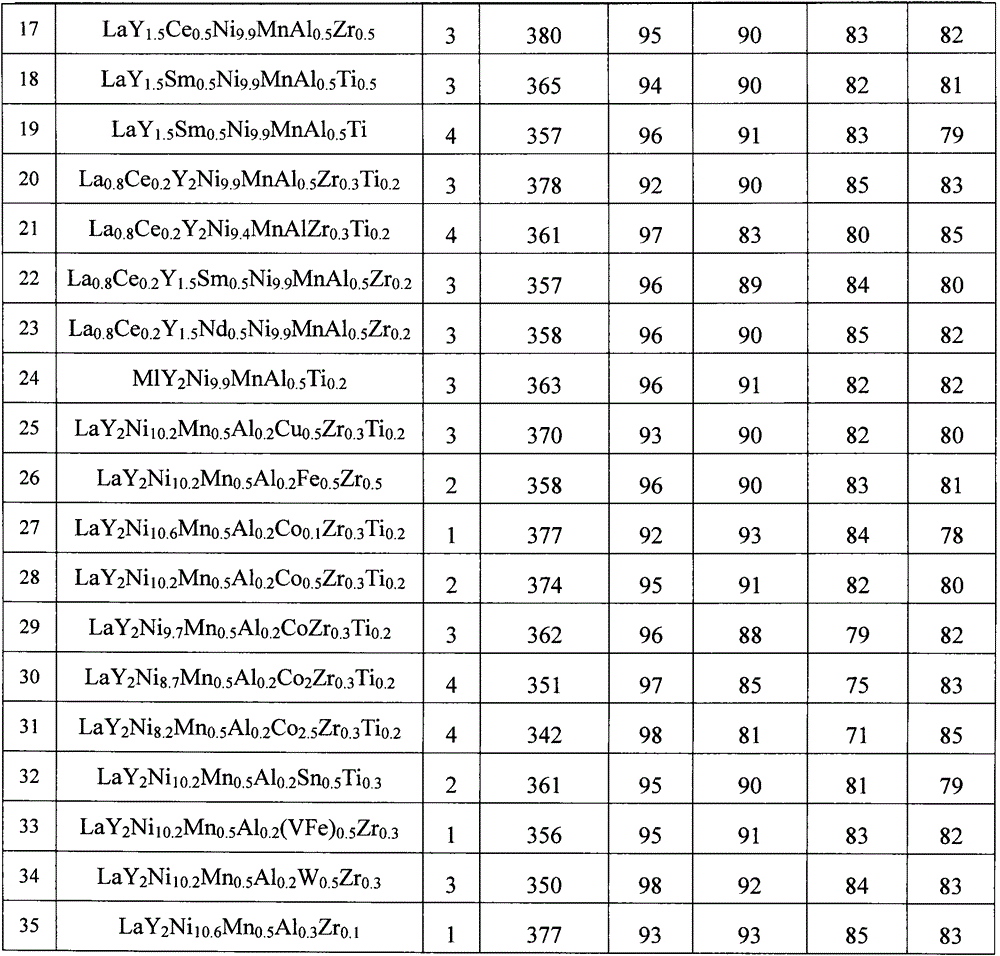

Examples

Embodiment 12

[0022] The alloys described in Example 12 and Example 13 were prepared using the same ratio of raw materials. The alloy described in Example 12 is prepared by the aforementioned high-temperature smelting-quick quenching method. The process is as follows: the purity of each elemental metal or intermediate alloy raw material in the composition is >99.0%, and the ratio of the chemical molecular formula is calculated and each raw material is accurately weighed ( Raw materials that are easy to burn need to increase the ratio in an appropriate amount), put the raw materials into Al 2 o 3 The crucible is evacuated to 3.0Pa and filled with inert gas Ar to 0.055MPa. Heat up and melt, keep warm for about 6 minutes and then quickly solidify. The speed of the quick-setting copper roller is 3.4m / s. The copper roller is usually fed with cooling water, and the temperature of the cooling water is 25°C.

Embodiment 13

[0023]The alloy described in Example 13 can also be prepared by high-temperature smelting-quick quenching method, and an annealing heat treatment step is added in the process, specifically: the purity of each elemental metal or intermediate alloy raw material in the composition is >99.0%, and the ratio is calculated according to the chemical molecular formula Calculate and accurately weigh each raw material (the proportion of easy-to-burn raw materials needs to be increased in an appropriate amount), and put the raw materials into Al 2 o 3 The crucible is evacuated to 3.0Pa and filled with inert gas Ar to 0.055MPa. Heat up and smelt, keep warm for about 6 minutes and then quickly solidify. The speed of the quick-setting copper roller is 3.4m / s. The copper roller is usually fed with cooling water, and the temperature of the cooling water is 25°C. The quick-setting alloy flakes were annealed and heat-treated at 750°C for 8 hours under the protection of vacuum or inert gas.

Embodiment 24

[0024] M1 in Example 24 is a lanthanum-rich mixed rare earth metal, which contains about 64% of La, about 25% of Ce, about 3% of Pr, and about 8% of Nd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com