Titanium and titanium alloy surface micro-nano structure modification method

A technology of micro-nano structure and modification method, applied in the field of titanium and titanium alloy surface treatment in metal surface treatment, can solve the problems of easy infection, poor osseointegration ability, etc., to avoid drug side effects, good bonding performance, good osseointegration effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

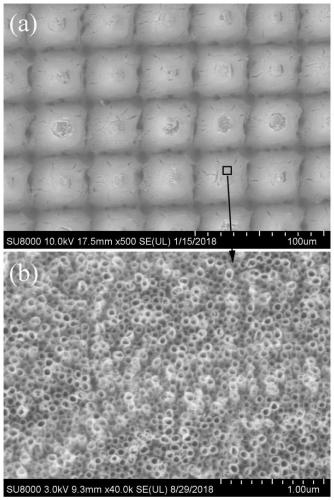

[0028] Embodiment 1: pure titanium surface micro-nano structure modification

[0029] Step 1: Femtosecond laser machining of microcolumn periodic structure on pure titanium surface

[0030] 1-1 After the surface of the medical-grade pure titanium sample is sanded and polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes, and finally placed in an oven to dry for later use.

[0031] 1-2 Put the cleaned pure titanium sample into the femtosecond laser processor, and control the sample stage through the program to realize the scanning irradiation processing on the surface of the sample. The processing parameters are: femtosecond laser pulse energy is 2.1J / cm 2 , the scanning speed is 400mm / s, the number of scanning is 30, and the scanning interval is adjusted to 40μm, the processing of the micro-column periodic structure on the surface of pure titanium can be realized. The height of the microcolumns is 70 μm.

[0032] Step 2: Pr...

Embodiment 2

[0040] Embodiment 2: Ti5Zr alloy surface micro-nano structure modification

[0041] Step 1: Femtosecond laser machining of micro-column periodic structure on the surface of Ti5Zr alloy

[0042] 1-1 After the surface of the Ti5Zr alloy is sanded and polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes, and finally placed in an oven for drying.

[0043] 1-2 Put the cleaned Ti5Zr alloy sample into the femtosecond laser processor, and control the sample stage through the program to realize scanning irradiation processing on the surface of the sample. The processing parameters are: femtosecond laser pulse energy is 2.1J / cm 2 , the scanning speed is 400mm / s, the number of scanning is 30, and the scanning interval is adjusted to 40μm, the processing of the micro-column periodic structure on the surface of pure titanium can be realized. The height of the microcolumns is 70 μm.

[0044] Step 2: Preparation of nanotubes by anodic ox...

Embodiment 3

[0051] Embodiment 3: Ti15Zr alloy surface micro-nano structure modification

[0052] 1-1 After sanding and polishing the surface of the Ti15Zr alloy, use acetone, absolute ethanol and deionized water to ultrasonically clean it for 15 minutes, and finally put it in an oven to dry for later use.

[0053] 1-2 Put the cleaned Ti15Zr alloy sample into the femtosecond laser processor, and control the sample stage through the program to realize scanning irradiation processing on the surface of the sample. The processing parameters are: femtosecond laser pulse energy is 2.1J / cm 2 , the scanning speed is 400mm / s, the number of scanning is 30, and the scanning interval is adjusted to 40μm, the processing of the micro-column periodic structure on the surface of pure titanium can be realized. The height of the microcolumns is 70 μm.

[0054] Step 2: Preparation of nanotubes by anodic oxidation on the periodic structure of microcolumns on the surface of pure titanium

[0055] 2-1 Clean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com