Magnetic graphene-supported nano zero-valent iron composite material as well as preparation method and application thereof

A technology of magnetic graphene and nano-zero-valent iron, which is applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, and can solve problems such as agglomeration of nano-zero-valent iron and loose combination of nano-zero-valent iron and graphene , to achieve the effect of improving surface activity, good magnetic properties and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of magnetic graphene-loaded nano-zero-valent iron composites

[0031] A method for preparing a magnetic graphene-loaded nano-zero-valent iron composite material, the specific steps of which are:

[0032] Step 1: Take a 500 mL flask and place it in an ice bath, and pour 1.0 g of graphite powder, 1.0 g of sodium nitrate and 46.0 ml of concentrated sulfuric acid into the flask and mix them. Then slowly add 4.0 g of potassium permanganate under magnetic stirring. After 1 h, the mixture was transferred to an oil bath, controlled for 35 ◦ Stir at C for 1 h. Then carefully add 60.0 mL deionized water, the temperature of the solution rises by about 90 ◦ C and keep for 30min. After that, 140 mL of deionized water and 20.0 mL of 30% hydrogen peroxide were added to the flask. After the solution was mixed, the solution was poured out, centrifuged and washed several times with 30% HCl solution, and then washed several times with deionized water, at 60 ◦ ...

Embodiment 2

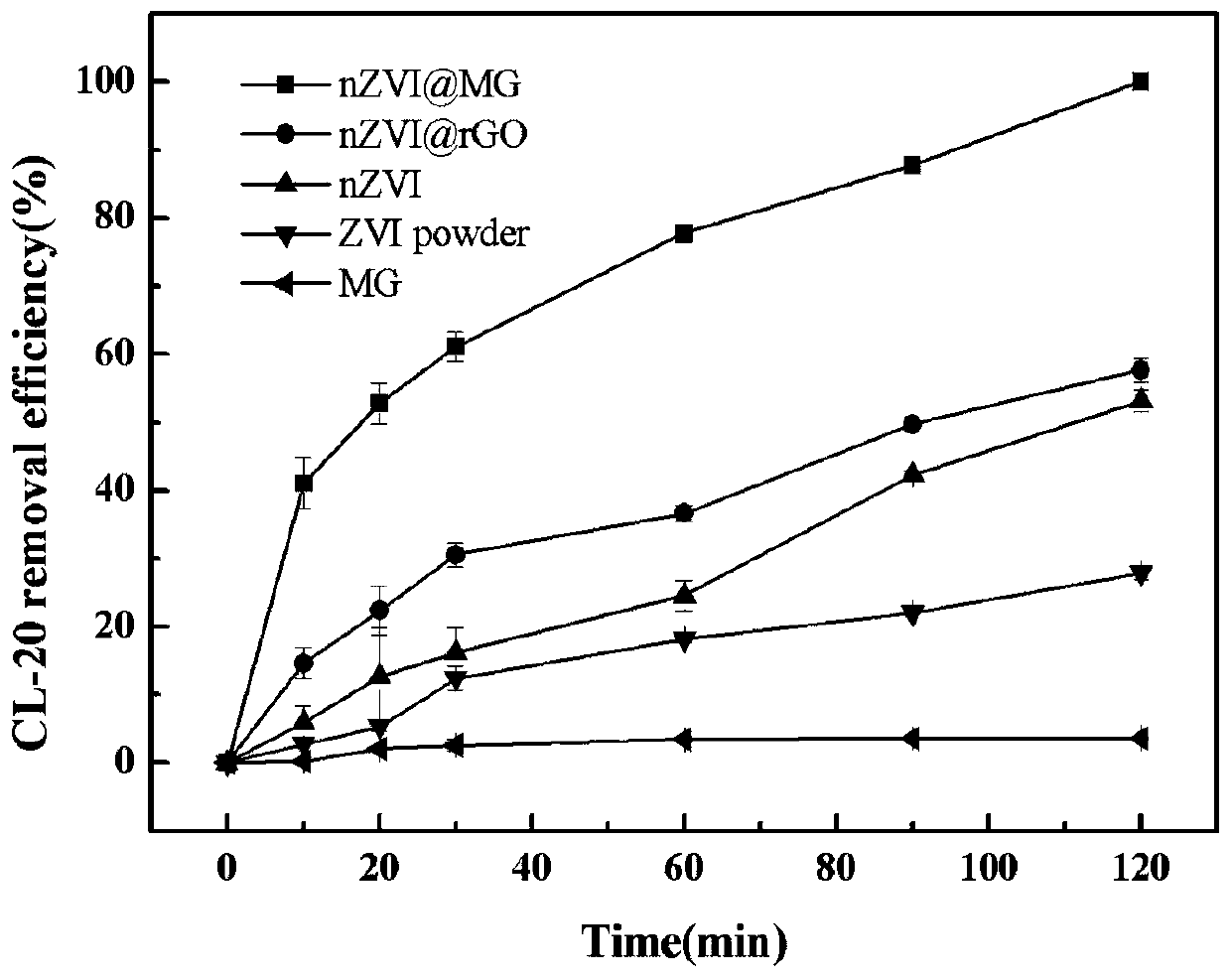

[0037] Example 2: Application of magnetic graphene-loaded nano-zero-valent iron composite material to remove CL-20 in wastewater

[0038] In order to form an experimental comparison, under the same experimental conditions, magnetic graphene (MG), commercial iron powder (nZVIpowder), nano-zero-valent iron (nZVI), graphene-supported nano-zero-valent iron composite (nZVI@rGO) and Removal effect of magnetic graphene-supported nano zero-valent iron composite (nZVI@MG) on CL-20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com