Method and device for belt-type adsorption separation

An adsorption separation and equipment technology, applied in the field of belt adsorption separation methods and equipment, can solve the problems of continuous whole process, difficult washing and desorption processes, and difficult recovery of adsorbents, and achieves easy recovery, broad application prospects, and easy continuous effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

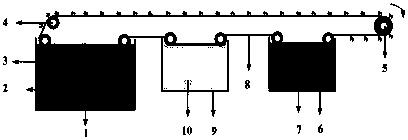

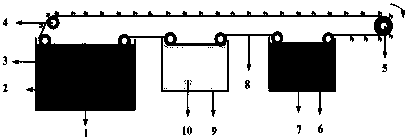

[0021] Take the example of separating bovine serum albumin (a type of biomolecule) in suspension. First, coat a layer of two-component epoxy resin adhesive on a tape-shaped carrier with a length of 200 cm and a width of 5 cm, then evenly coat the agarose gel on the adhesive, and ventilate and dry. Finally, connect the first and last two ends with a needle thread to make it a ring-shaped adsorbent band 8. figure 1 Run on the belt separator shown. The device mainly includes an adsorption tank 1, a desorption tank 6, a washing tank 9, a fixed-position pulley 4 arranged on the top of each tank and an annular adsorbent belt 8 driven by it; the annular adsorbent belt 8 is driven by a motor drive wheel 5 Continuously driven by the pulley 4, it circulates and rotates continuously among the adsorption tank 1, the desorption tank 6 and the washing tank 9, thereby realizing the continuous process of adsorption, desorption and washing.

[0022] Utilize above-mentioned belt type adsorpti...

Embodiment 2

[0027] Take the treatment of heavy metal ions (a type of metal ion) in wastewater as an example. In this experiment, the more typical toxic heavy metal ion divalent nickel was used as the removal object, and a film with a length of 200 cm and a width of 5 cm coated with a thin layer of activated carbon was used as the adsorbent belt to prepare Ni 2+ Concentration is the solution 300ml of 40ppm, as raw material liquid, adds the sludge in the pond in a small amount to raw material liquid, is standby as the raw material liquid to be separated.

[0028] The specific operation is: add 300ml of the prepared divalent nickel ion raw material solution into the adsorption tank 1, adjust the electric drive wheel 5 to control the annular adsorbent belt 8 to run at the speed of 2r / min to the top of the adsorption tank 1 and the adsorption tank 1 The liquid surface of the middle feed liquid just touches for adsorption. Ni 2+ Captured by the continuously rotating adsorbent belt 8 and taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com