Halohydrocarbon gas fire extinguishing system with safety additives

A fire extinguishing system and halogenated hydrocarbon technology, applied in fire prevention equipment, fire rescue, etc., can solve problems such as human hazards, achieve efficient absorption, improve the overall fire extinguishing effect, and have strong insulation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

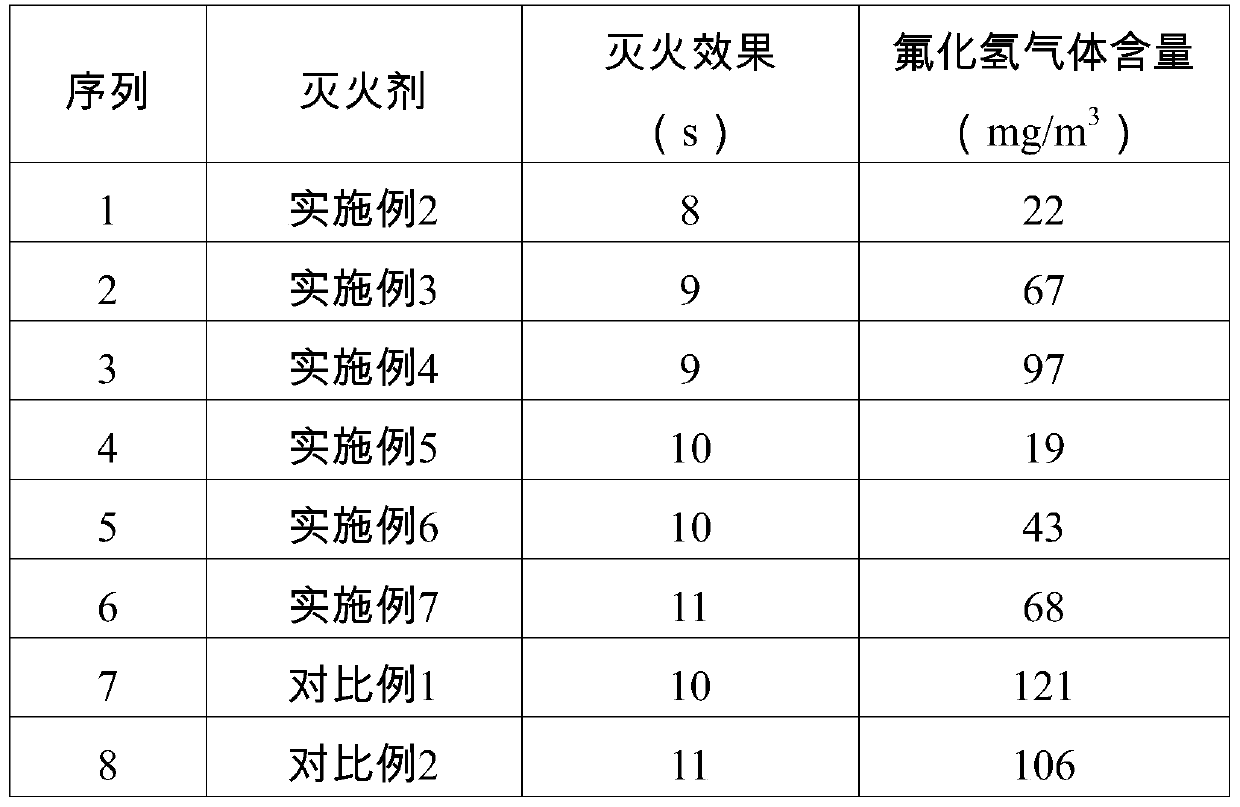

Examples

Embodiment 1

[0029] This embodiment is used to illustrate the structure and use method of the halogenated hydrocarbon gas fire extinguishing system with safety additives according to the present invention.

[0030] The halogenated hydrocarbon gas fire extinguishing system method consists of a halogenated hydrocarbon fire extinguishing agent 1, a halogenated hydrocarbon fire extinguishing agent tank 2, a water tank 3, a pressure source 4, a one-way valve 5, a safety additive mixer 6, a safety additive 7, a fire extinguishing Pipeline 8, charged fire extinguishing nozzle 9 forms.

[0031] The safety additive is mixed with a halogenated hydrocarbon fire extinguishing agent by a mechanical pump-in proportional mixer. The pressure source 4 of the halogenated hydrocarbon gas fire extinguishing system adopts a pump set. When extinguishing a fire, the pressure source 4 extracts the halogenated hydrocarbon fire extinguishing agent 1 in the halogenated hydrocarbon fire extinguishing agent tank 2, p...

Embodiment 2

[0033] This embodiment is used to illustrate the composition of the halogenated hydrocarbon gas fire extinguishing system with safety additives according to the present invention.

[0034] In the halogenated hydrocarbon gas fire extinguishing system described in embodiment 1:

[0035] The halogenated hydrocarbon fire extinguishing agent is a mixture of 2-bromopentafluoropropene and 1-bromo-2,3,3,3-tetrafluoropropene in a ratio of 4:6. The safety additive is an aqueous solution of a mixture of sodium carbonate and triethylamine, and the aqueous solution contains 2% of sodium carbonate and 0.1% of triethylamine.

[0036] The safety additive is mixed with a halogenated hydrocarbon fire extinguishing agent by a mechanical pump-in proportional mixer. The mixing ratio of the safety additive to the halogenated hydrocarbon fire extinguishing agent is 1:50.

Embodiment 3

[0038] The difference between this embodiment and embodiment 2 is:

[0039] The safety additive is 2% sodium carbonate aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com