Non-foaming and low surface tension surfactant and preparation method and application thereof

A technology of low surface tension and surfactant, applied in the field of preparation and application of fine chemicals, can solve the problem of high surface tension, and achieve the effects of convenient operation, simple production process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

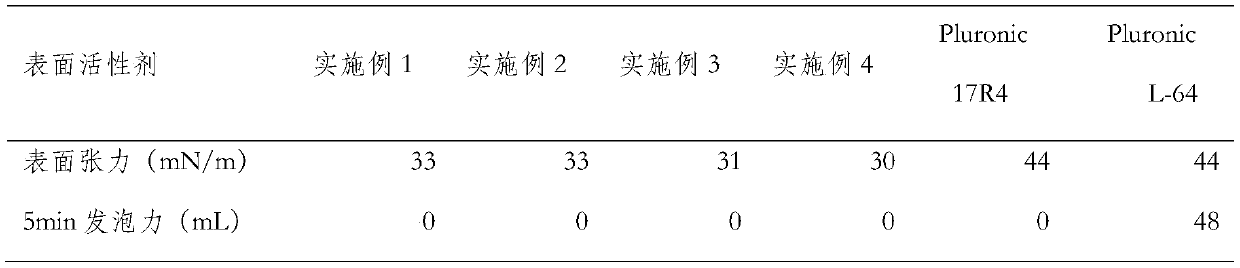

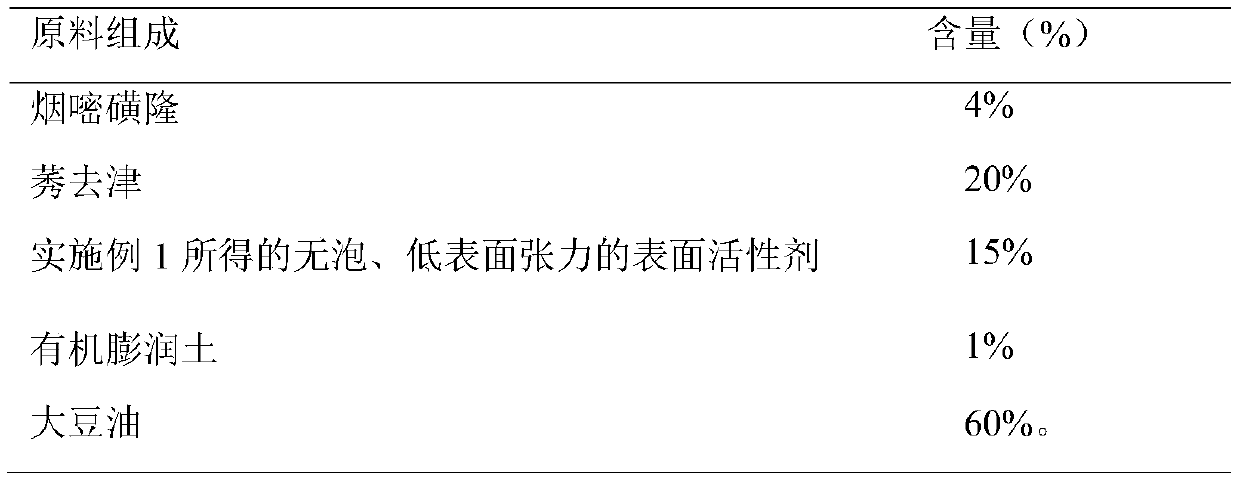

Examples

Embodiment 1

[0059] A kind of non-foaming, low surface tension surfactant, calculated by mass percentage, its raw material composition and content are as follows:

[0060] Active Ingredient A 60%

[0061] Active ingredient B 40%;

[0062] The active component A is PEG400MO, and the PEG400MO is polyethylene glycol monooleate with an average molecular weight of 400;

[0063] The active component B is NP-4, and the NP-4 is nonylphenol polyoxyethylene ether with an average EO number of 4.

[0064] The preparation method of above-mentioned a kind of foam-free, low surface tension surfactant, specifically comprises the steps:

[0065] Add active component A and active component B into the reaction kettle in sequence, control the rotation speed to 80-100r / min and stir evenly to obtain a surfactant with no foam and low surface tension.

Embodiment 2

[0067] A kind of non-foaming, low surface tension surfactant, calculated by mass percentage, its raw material composition and content are as follows:

[0068] Active Ingredient A 57%

[0069] Active ingredient B 43%;

[0070] The active component A is PEG400MO, and the PEG400MO is polyethylene glycol monooleate with an average molecular weight of 400:

[0071] The active component B is NP-4, and the NP-4 is nonylphenol polyoxyethylene ether with an average EO number of 4.

[0072] The above-mentioned preparation method of a foam-free, low surface tension surfactant, the preparation process is the same as in Example 1.

Embodiment 3

[0074] A kind of non-foaming, low surface tension surfactant, calculated by mass percentage, its raw material composition and content are as follows:

[0075] Active Ingredient A 48%

[0076] Active ingredient B 52%;

[0077] The active component A is PEG400MO, and the PEG400MO is polyethylene glycol monooleate with an average molecular weight of 400:

[0078] The active component B is NP-4, and the NP-4 is nonylphenol polyoxyethylene ether with an average EO number of 4.

[0079] The above-mentioned preparation method of a foam-free, low surface tension surfactant, its preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com