Fluorescent dye and metal organic framework MOFs composite material, preparation method and application thereof

A metal-organic framework and fluorescent dye technology, applied in the field of fluorescent dye and metal-organic framework MOFs composite materials and their preparation, to achieve the effects of avoiding fluorescence quenching, mild preparation conditions, and wide emission range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The synthesis of embodiment 1MOFs

[0047] A typical synthesis strategy is: Weigh 0.8g of zinc nitrate hexahydrate and ultrasonically dissolve it in 50mL of DMF, then weigh 1.6g of dimethylimidazole and add it to the above solution, then stir at 2000r / min for 1h at room temperature to obtain The white powder material was cleaned by centrifugation with 50mL DMF, ethanol and acetone, and then exchanged with acetone for three days to remove the residual organic solvent (DMF) in the composite material, and then dried under vacuum for 8h to obtain ZIF-8 (2 - methylimidazole zinc salt).

Embodiment 2

[0048] Synthesis of Example 2 Single Dye and MOFs Composite Material

[0049] First, dissolve 5-50 mg of the selected fluorescent dye pyrene in 50 mL of DMF, weigh 0.8 g of zinc nitrate hexahydrate and ultrasonically dissolve it in the above solution, then weigh 1.6 g of dimethylimidazole and add it to the above solution, and then , at 2000r / min, stirring for 1h, the obtained white powder material was washed by centrifugation with 50mL DMF, ethanol and acetone respectively, and then exchanged with acetone for three days, in order to remove the residual organic solvent (DMF) in the composite material, and then under vacuum condition Dry 8h.

Embodiment 3

[0050] Synthesis of Example 3 Double Dye and MOFs Composite Material

[0051]Two dyes pyrene and fluorescein with masses of 5mg and 20mg, 10mg and 20mg, 10mg and 60mg, 6mg and 120mg, 12mg and 120mg were dissolved in 50mL DMF respectively, and 0.8g of zinc nitrate hexahydrate was ultrasonically dissolved in the above solution, then weigh 1.6g dimethylimidazole and add it to the above solution, then at room temperature, at 2000r / min, stir for 1h, the white powder material obtained is washed with 50mLDMF, ethanol and acetone, and then washed with acetone Exchange for three days, in order to remove the residual organic solvent (DMF) in the composite material, and then dry under vacuum for 8h.

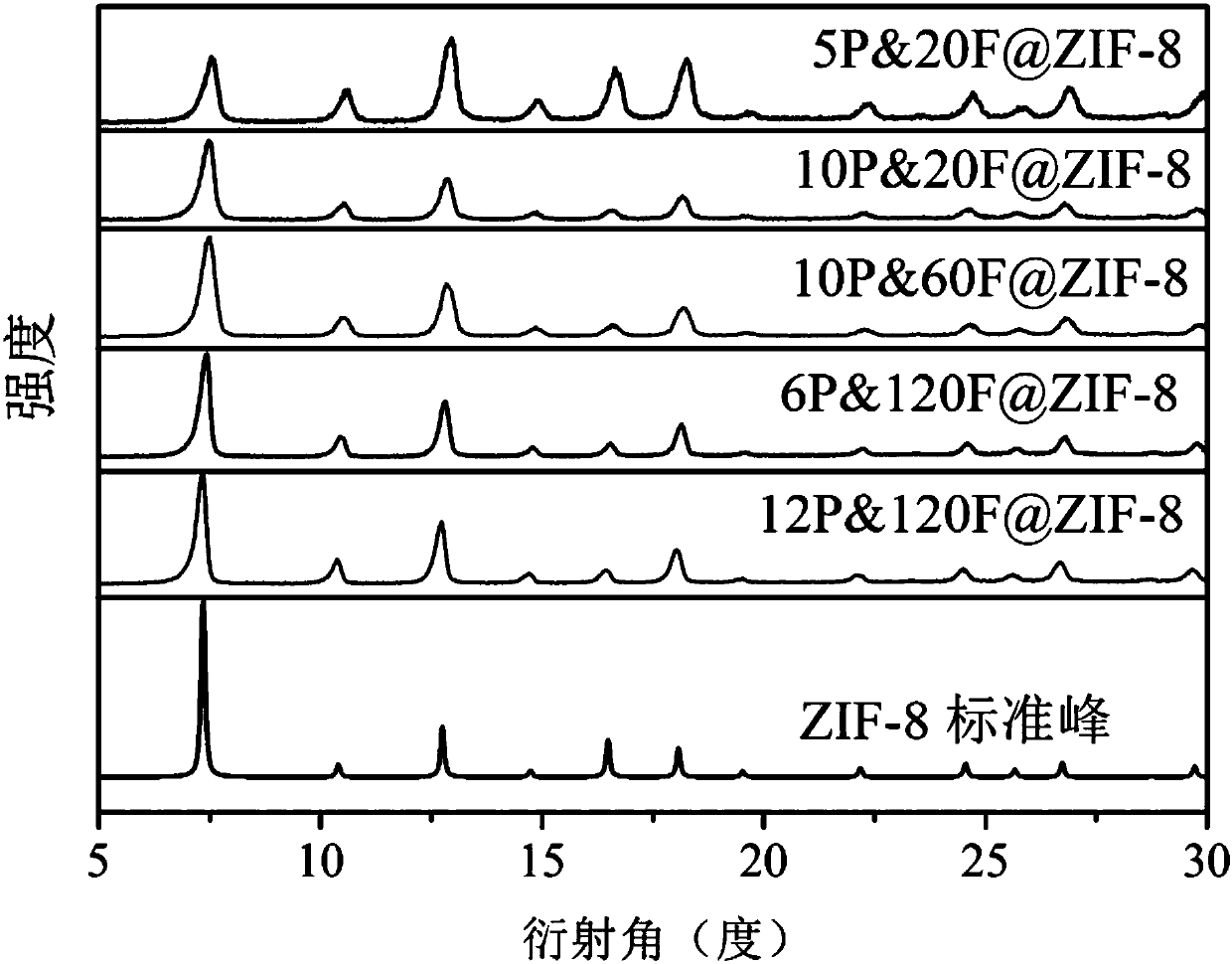

[0052] A series of characterizations were performed on the double dye and MOFs composite material prepared in Example 3, and the following results were obtained:

[0053] figure 1 The powder diffraction patterns of the composite materials with different proportions prepared in Example 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com