Tail gas purifier for controlling toxic and harmful waste gas discharged at end of chemical plant chimney

A technology for exhaust gas purifiers and chemical plants, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as inability to absorb and control, and achieve strong effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

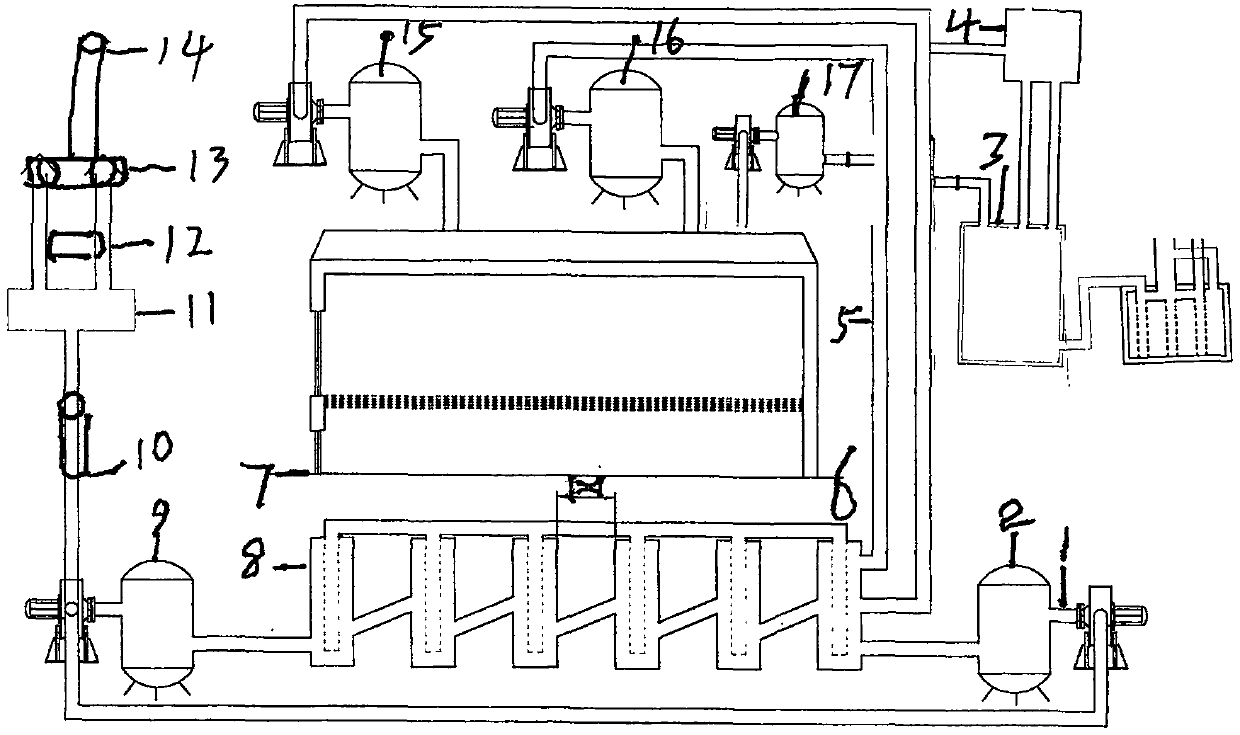

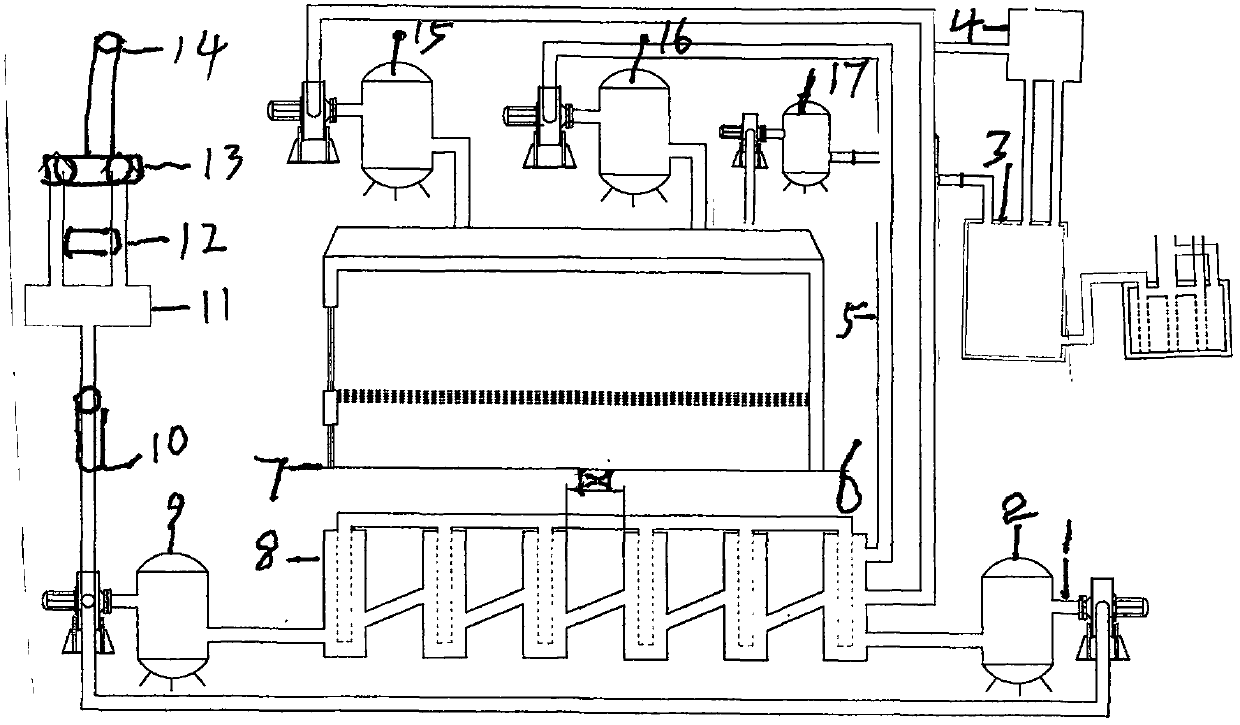

[0012] As shown in the figure, the present invention controls the poisonous and harmful exhaust gas tail gas purifier at the end of the smoke exhaust chimney of the chemical plant, which consists of a control smoke exhauster 1, a purifying water vapor white smoke device 2, a VOC low temperature controller 3, a benzene gas purifier 4, and a toluene Cooling exhaust pipe 5, xylene cooler 6, control sewage device 7, exhaust gas cleaner 8, control latex particle collector 9, steam purifier 10, non-methane total hydrocarbon emission reducer 11, tail gas smoke eliminator 12, suction Dust separator 13, malodorous gas deodorization discharger 14, degassing dust remover 15, circulation induced air device 16, disinfection and deodorization medicinal liquid device 17 are formed.

[0013] The VOC low-temperature controller 3 of the present invention is provided with toluene cooling exhaust pipes 5, and the spacing is gradually spaced out. An exhaust gas cleaner 8 is installed above the tolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com