A Construction Method of Low Friction Coefficient Pavement in Dry State

A low-friction coefficient and construction method technology, applied to roads, roads, on-site paved condensate pavements, etc., can solve the problems of vehicles unable to drive and test normally, complex road surface construction technology, and large resource consumption, etc., to achieve good mixing Solubility, reduce friction coefficient, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

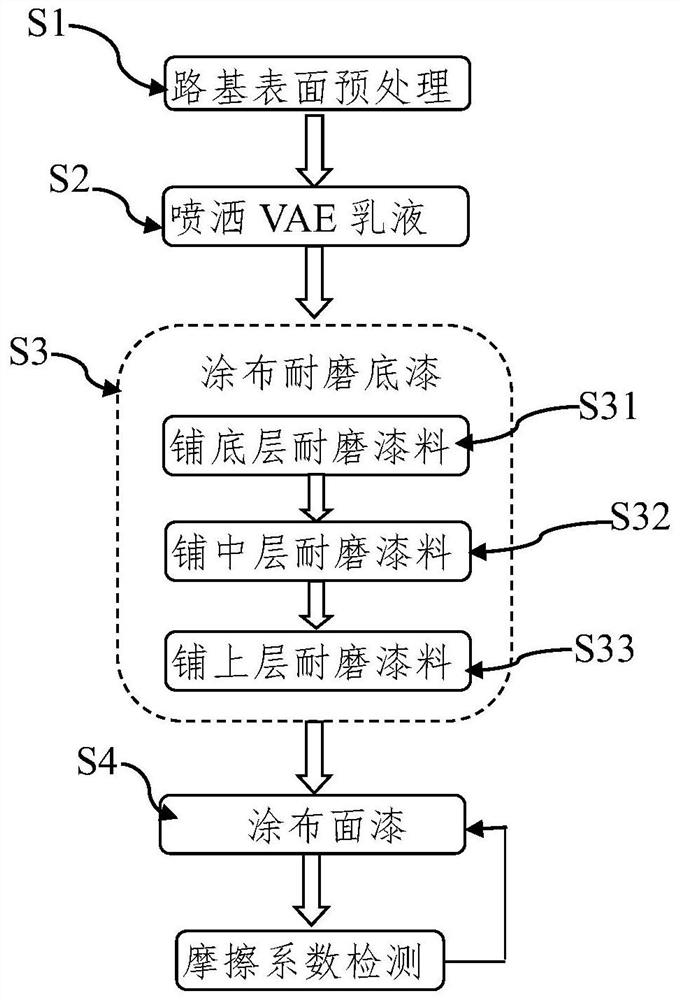

[0045] Such as figure 1 As shown, it is a flow chart of the construction method of the low friction coefficient road surface in the dry state according to the preferred embodiment 1 of the present invention. combine figure 1 Come understand embodiment 1 of the present invention, it comprises steps:

[0046] Step 1. Pretreatment of the asphalt subgrade surface to be constructed

[0047] The surface treatment of the asphalt subgrade is mainly to clean the floating ash, loose small particles and uneven surface on the surface. This process helps to improve the adhesion between the various coatings and the surface of the asphalt roadbed during the construction process. The better the asphalt pavement is treated, the more it can avoid peeling and hollowing in the later stage. The specific operation of this step can be: first use a high-precision grinder to dry-grind the surface of the asphalt pavement to 1mm, and then use a ruler ≥ 3 meters to confirm the flatness after grinding;...

Embodiment 2

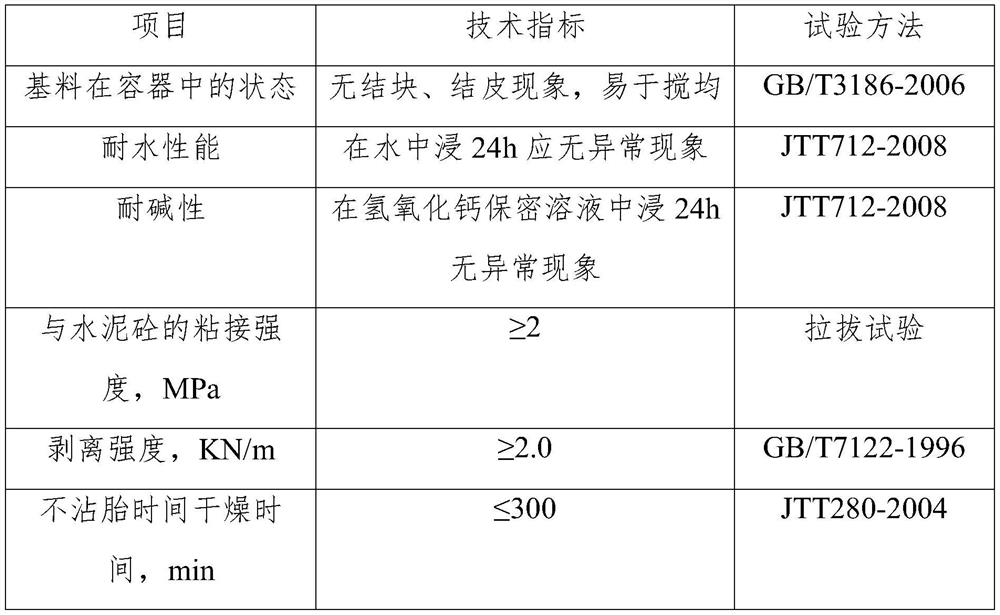

[0073] This embodiment is a further improvement on the basis of embodiment 1, the only difference is that in step 6, when preparing the topcoat, in order to take into account other requirements for the road surface in the industry, such as tire adhesion, further prolong the service life of the road surface and reduce the friction of the road surface Coefficient, improving construction performance, etc., the topcoat also needs to meet the following performance indicators:

[0074]

[0075] Refer to Embodiment 1 for other operating steps and methods of this embodiment, and detect the completed road surface, and the detection results are as follows:

[0076] Water resistance: No abnormal phenomenon after immersion in water for 24 hours; bonding strength with asphalt subgrade surface ≥ 2.0Mpa; after pavement construction is completed, the total amount of coating is 0.9Kg-1.2Kg / m 2 .

Embodiment 3

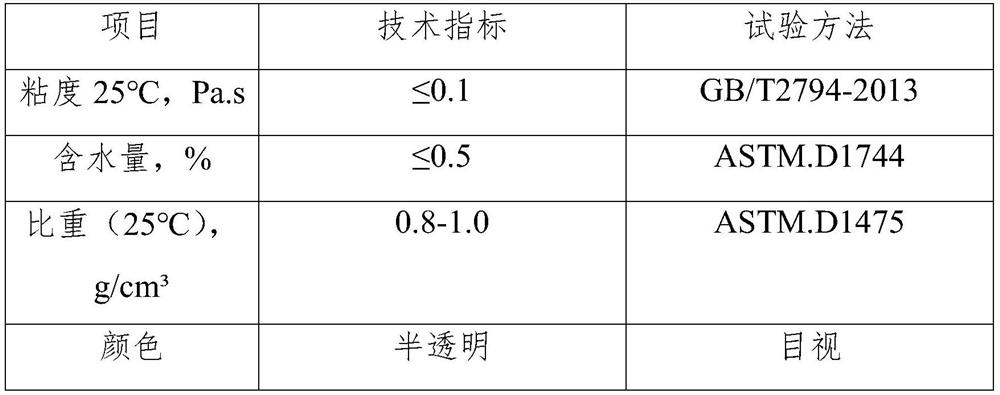

[0078] This embodiment is a further improvement on the basis of Embodiment 2, the difference is only that in step 5, when selecting the color paste or preparing the color paste, in order to take into account other requirements for the road surface in the industry, such as further prolonging the service life of the road surface, improving light resistance and Weather resistance, improving construction performance, etc., the color paste also needs to meet the following performance indicators:

[0079] project technical indicators experiment method tinting strength Less dosage, strong coloring power GB / T 21473-2008 Lightfastness ≥5 GB / T 21473-2008 weather resistance ≥3 GB / T 21473-2008

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com