Polycarbonate alloy and preparation method thereof

A polycarbonate and alloy technology, applied in the field of polycarbonate alloy and its preparation, can solve the problems of difficult uniform dispersion, difficult processing, large addition amount, etc., and achieve the effects of suppressing cracking, improving stability, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

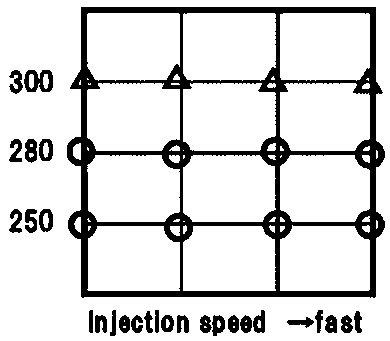

Image

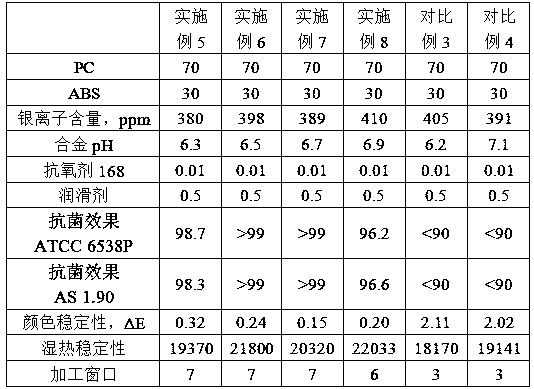

Examples

Embodiment Construction

[0045] The present invention is further illustrated by the following examples, but the present invention is not limited by the following examples.

[0046] The sources of raw materials used in the present invention are as follows, but are not limited by the following raw materials.

[0047] Silver ion source: Silver ion antibacterial agent, IKM50G, Japan Zeomic;

[0048] Liquid acid: Phosphoric acid;

[0049] Flame retardant A: phenoxyphosphazene;

[0050] Flame retardant B: bisphenol A bis(diphenyl phosphate);

[0051] Flame retardant C: melamine polyphosphate;

[0052] Lubricants: stearate lubricants, PETS;

[0053] The preparation method of embodiment polycarbonate alloy: according to proportioning, polycarbonate, ABS resin, silver ion antibacterial agent, the porous foaming polycarbonate or the porous foaming ABS that exists liquid acid, flame retardant are added high-speed mixer Mix evenly in a feeder, then add to a twin-screw extruder, melt and mix at a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com