Hollow carbon sphere and preparation method and application thereof

A technology of hollow carbon spheres and polymerization reaction, applied in the direction of nano-carbon, etc., can solve the problems of unevenness, large wall thickness of hollow carbon spheres, cumbersome steps, etc., and achieve the effect of large specific surface area, large pore volume, and controllable wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix resin monomer-resorcinol, ammonia water, deionized water, absolute ethanol, surfactant-hexadecyltrimethylammonium bromide (CTAB) and mix well to prepare solution A; Add ester (TEOS) to solution A to prepare solution B, keep the temperature of solution B at 40°C, hydrolyze ethyl orthosilicate for 1 hour to prepare silica suspension; suspend to silica at a dropping rate of 1ml / min Add formaldehyde solution to the liquid and carry out the first-stage polymerization reaction at 35°C for 24 hours; then transfer the solution to the reactor, keep the solution temperature at 80°C, and carry out the second-stage polymerization: hydrothermal reaction for 30 hours, and prepare two Silica-resin composite balls: After washing, filtering and drying the silica-resin composite balls, transfer them to a tube furnace, raise the temperature to 600°C in a nitrogen atmosphere, and keep the temperature for 20 hours to prepare silica-carbon composite balls ; The silicon dioxide-carbon com...

Embodiment 2~10

[0041] Examples 2 to 10, the preparation process is the same as that of Example 1, except that the molar concentration of resin monomer, the mass fraction of orthosilicate, the mass fraction of surfactant, and the volume ratio of alcohol and water are different, as shown in Table 1 .

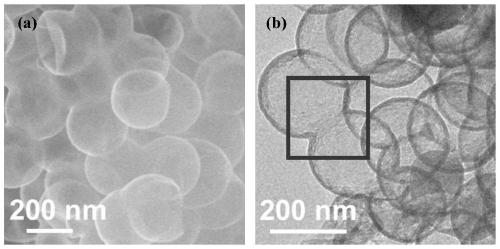

[0042] The hollow carbon sphere obtained in embodiment 2 is denoted as MF-2.2-20, SEM figure (a) and TEM figure (b) are as figure 2 , it can be seen that the particle size of the hollow carbon spheres is basically the same, about 250nm, and the wall thickness is about 15nm, and the spheres are connected to each other. This is further verified in the box marked in the TEM image. .

[0043] The hollow carbon sphere obtained in embodiment 3 is denoted as MF-1.1-20, SEM figure (a) and TEM figure (b) are as image 3 , it can be seen that the particle size of the hollow carbon spheres is basically the same, about 250nm, and the wall thickness is about 30nm, and the spheres are connected to each oth...

Embodiment 11~20

[0047] The preparation process of Examples 11-20 is the same as that of Example 1, except that the hydrolysis temperature and time of tetraethyl orthosilicate, the polymerization reaction temperature and time, and the calcination temperature and time are different, as shown in Table 2.

[0048] Table 2.

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com