Peeling method of mica flakes

A mica flake and peeling technology, which is applied in the field of mica flake peeling, can solve problems affecting the normal use of mica flakes, scratches, etc., and achieve the effects of excellent dielectric strength, slight scratches, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

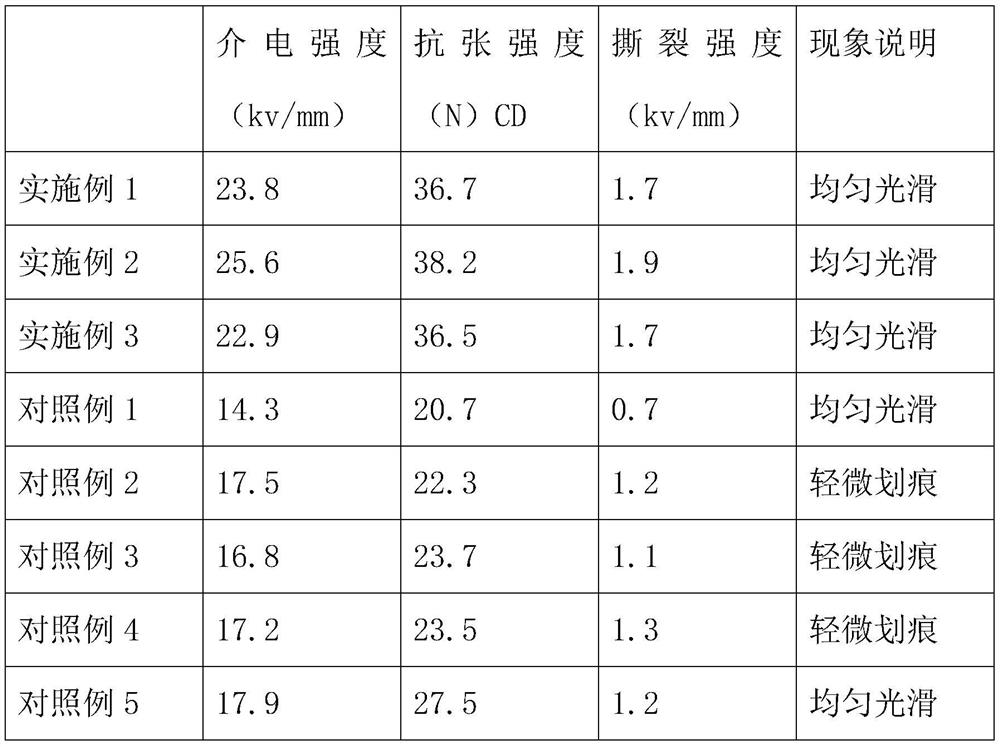

Examples

Embodiment 1

[0021] The preparation method of the soaking solution is as follows: 1) Mix 50 parts of rice-washing water and 0.4 nano-titanium oxide, adjust the pH of the solution to 6.5, and ultrasonically disperse for 10 minutes;

[0022] 2) Add 2 parts of sodium chloride, 3 parts of glycerin, 4 parts of lemon essential oil, 2 parts of tourmaline powder, and 10 parts of polyvinyl alcohol, adjust the pH of the solution to be neutral, and mix and stir evenly.

[0023] 1) select mica sheet: the synthetic mica sheet is carried out sampling inspection, selects the qualified mica sheet as raw material for subsequent use;

[0024] 2) Pretreatment: put the mica sheet selected in step 1) into the soaking liquid and soak for 2 hours. Ultrasonic cooperation is used during soaking. The ultrasonic wave is used for 20 minutes. The formula of the soaking liquid is as follows: 50 parts of rice washing water, chlorine 2 parts of sodium chloride, 3 parts of glycerin, 4 parts of lemon essential oil, 2 parts...

Embodiment 2

[0028] The preparation method of the soaking solution is as follows: 1) Mix 60 parts of rice washing water and 0.6 nano-titanium oxide, adjust the pH of the solution to 6.6, and disperse it ultrasonically for 10 minutes;

[0029] 2) Add 6 parts of sodium chloride, 5 parts of glycerin, 6 parts of lemon essential oil, 4 parts of tourmaline powder, and 13 parts of polyvinyl alcohol, adjust the pH of the solution to be neutral, and mix and stir evenly.

[0030] Stripping method:

[0031] 1) select mica sheet: the synthetic mica sheet is carried out sampling inspection, selects the qualified mica sheet as raw material for subsequent use;

[0032] 2) Pretreatment: Put the mica sheet selected in step 1) into the soaking liquid and soak for 3 hours. Ultrasonic cooperation is used during soaking. The ultrasonic wave is used for 230 minutes. The formula of the soaking liquid is as follows: 60 parts of rice washing water, chlorine 6 parts of sodium chloride, 5 parts of glycerin, 6 parts...

Embodiment 3

[0036] The preparation method of the soaking solution is as follows: 1) Mix 70 parts of rice washing water and 0.8 nano-titanium oxide, adjust the pH of the solution to 6.8, and disperse by ultrasonic for 10 minutes;

[0037] 2) Add 10 parts of sodium chloride, 8 parts of glycerin, 8 parts of lemon essential oil, 6 parts of tourmaline powder, and 16 parts of polyvinyl alcohol, adjust the pH of the solution to be neutral, and mix and stir evenly.

[0038] Stripping method:

[0039] 1) select mica sheet: the synthetic mica sheet is carried out sampling inspection, selects the qualified mica sheet as raw material for subsequent use;

[0040] 2) Pretreatment: put the mica sheet selected in step 1) into the soaking liquid and soak for 4 hours. Ultrasonic cooperation is used during soaking. The ultrasonic wave is used for 40 minutes. The formula of the soaking liquid is as follows: 70 parts of rice washing water, chlorine 10 parts of sodium chloride, 8 parts of glycerin, 8 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com