RC-IGBT structure and manufacturing method thereof

A manufacturing method and back metal technology, applied to the RC-IGBT structure, the manufacturing field of the RC-IGBT structure, can solve problems such as complex process flow and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

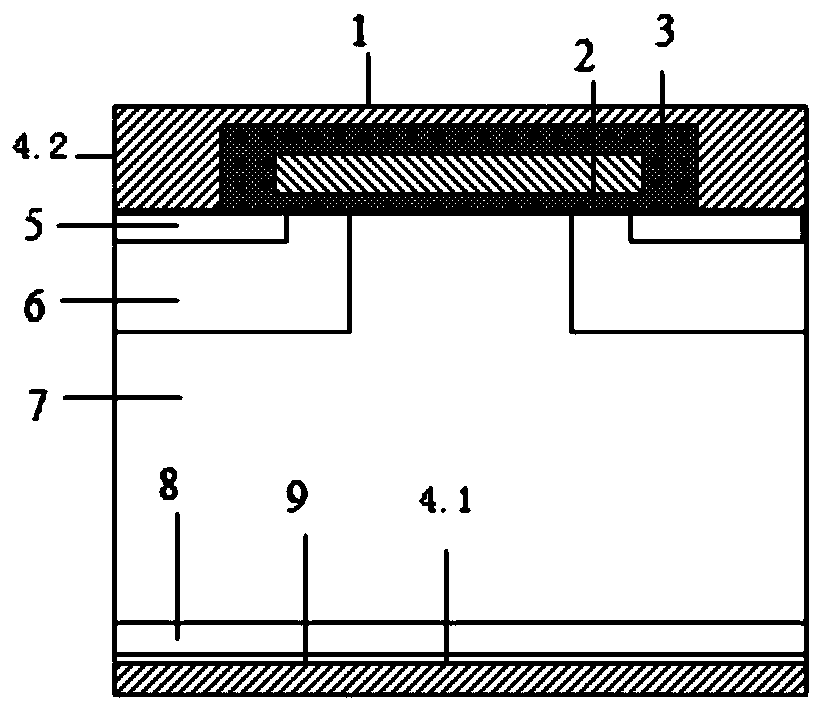

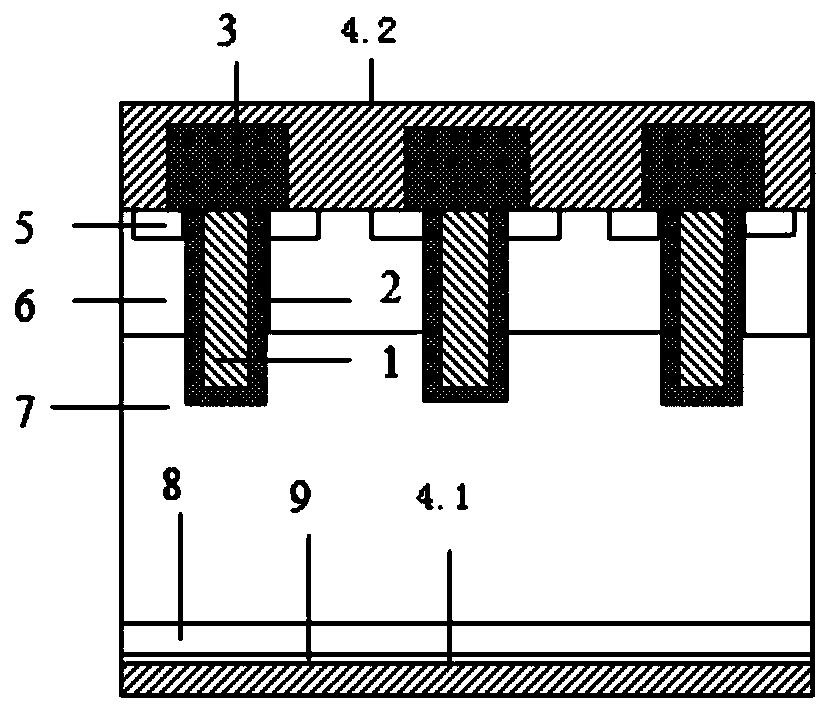

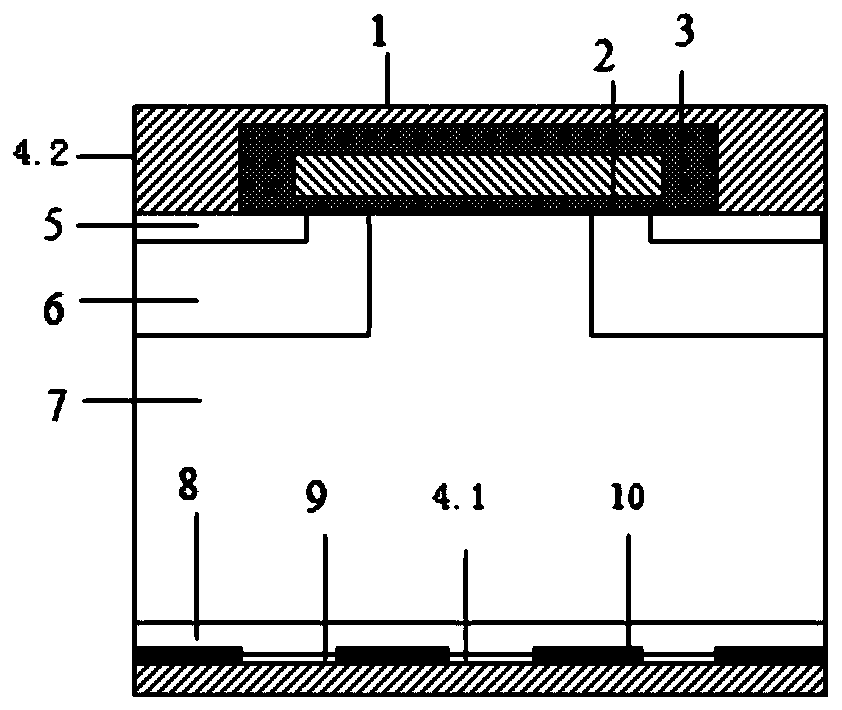

[0047] Such as Figure 5 As shown, the first embodiment of the RC-IGBT structure provided by the present invention, taking the trench gate RC-IGBT as an example, includes forming a collector electrode 9 on the back metal electrode 4.1, forming a buffer layer 8 on the collector electrode 9, and forming a buffer layer 8 on the buffer layer 8. A drift region 7 is formed, a body region 6 is formed on the drift region 7, a trench is arranged in the body region 6 and the drift region 7, an emitter 5 is formed in the body region 6 on both sides of the trench, and a gate oxide layer 2 is formed on the inner wall of the trench , the polysilicon gate 1 is formed in the gate oxide layer 2, the interlayer dielectric 3 is arranged in the front metal electrode 4.2 on the trench; a plurality of protrusions 8' are formed on the back metal electrode 4.1, and the protrusions 8' pass through the collector 9 extends into the buffer layer 8. Wherein, the emitter 5 is an N-type heavily doped regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com