MnO2/Fe2O3@ amorphous carbon composite material, aptamer sensor and preparation method and application thereof

A technology of amorphous carbon and composite materials, which is applied to the analysis of materials, electrochemical variables of materials, and material analysis through electromagnetic means, etc. In-situ detection, poor binding activity and other issues, to achieve good electrochemical activity, improve electrochemical activity, and enhance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The preparation method of the nucleic acid aptamer sensor of this embodiment adopts the following steps:

[0075] 1) 118.7mg MnCl 2 4H 2 O, 0.25g Na 3 C 6 h 5 o 7 2H 2 O and 0.3g PVP-K30 were dispersed in 30mL deionized water to form solution A; 66.0mg K 3 [Fe(CN) 6 ] was dispersed in 20 mL deionized water to form solution B. Add solution B to solution A and stir at room temperature for 10 min, then stand at room temperature for 24 h, centrifuge and wash the obtained precipitate 3 times with deionized water, and then vacuum-dry at 60°C to obtain ferromanganese Prussian blue analogue (expressed as MnFe PBA). MnCl 2 4H 2 O, K 3 [Fe(CN) 6 ] The molar ratio is 3:1.

[0076] 2) 130mg FeCl 3 and 40 mg MnFe PBA were dispersed in 5 mL deionized water to form a homogeneous suspension. Then 20 μL of pyrrole was added to the solution, reacted at room temperature for 30 min, and the product was collected by centrifugation, washed several times with ethanol and water...

Embodiment 2

[0082] The preparation method of the nucleic acid aptamer sensor of this embodiment is basically the same as the preparation method of the nucleic acid aptamer sensor Example 1, the only difference is that in step 1), MnCl 2 4H 2 The amount of O used is 79.16 mg, Na 3 C 6 h 5 o 7 2H 2 The dosage of O is 100mg, the dosage of PVP-K30 is 250mg, and the dosage of K 3 [Fe(CN) 6 ] The consumption is 66mg; Step 2) in, FeCl 3 , MnFe PBA, and pyrrole are respectively 48 mg, 40 mg, and 8 μL; in step 3), the calcination temperature is 350° C. and the time is 3 h.

Embodiment 3

[0084] The preparation method of the nucleic acid aptamer sensor of this embodiment is basically the same as the preparation method of the nucleic acid aptamer sensor Example 1, the only difference is that in step 1), MnCl 2 4H 2 The amount of O used is 158.32 mg, Na 3 C 6 h 5 o 7 2H 2 The dosage of O is 500mg, the dosage of PVP-K30 is 500mg, the dosage of K 3 [Fe(CN) 6 ] The consumption is 66mg; Step 2) in, FeCl 3 , MnFe PBA, and pyrrole are 196 mg, 40 mg, and 28 μL. In step 3), the calcination temperature is 450° C. and the time is 1 h.

[0085] The specific examples 1-3 of the nucleic acid aptamer sensor of the present invention respectively correspond to the products obtained in the above examples 1-3 of the preparation method of the nucleic acid aptamer sensor.

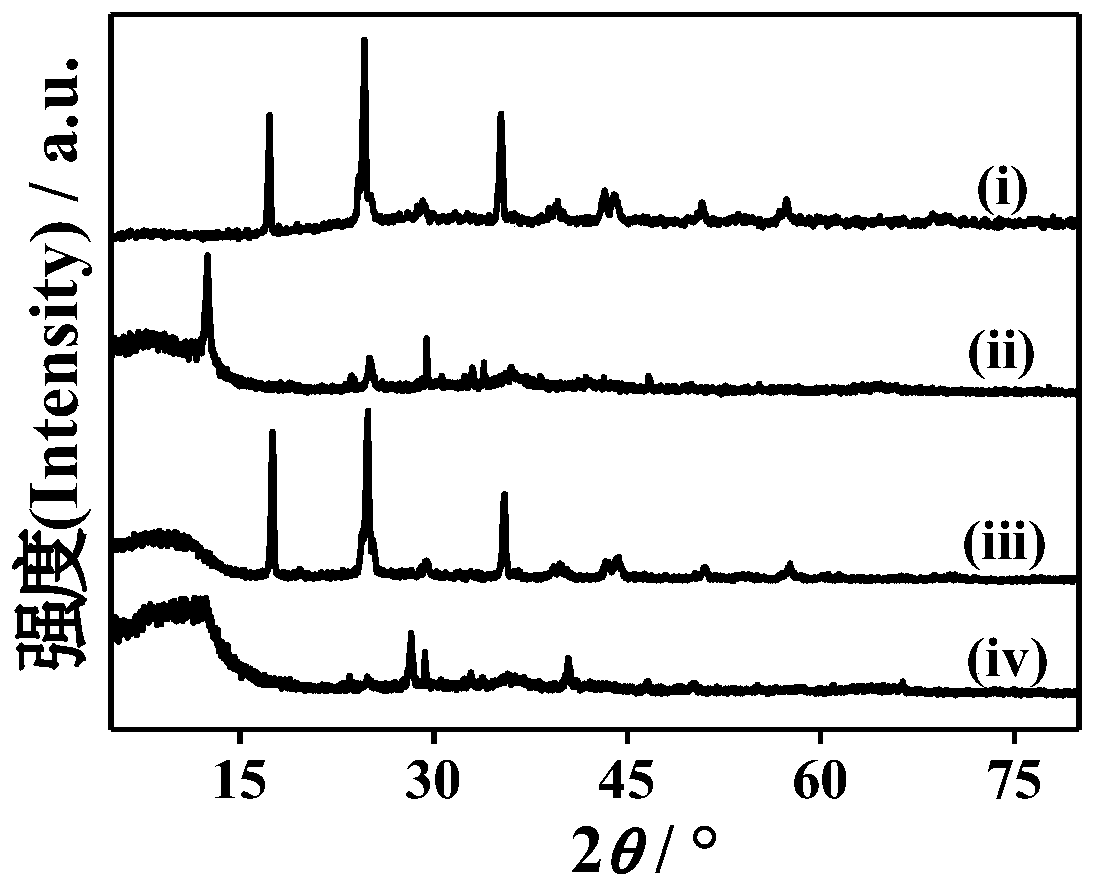

[0086] MnO of the present invention 2 / Fe 2 o 3 @Specific examples 1-3 of amorphous carbon composite materials correspond to the products obtained in step 3) of the above nucleic acid aptamer sensor p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com