Reliability evaluating method of electronic packaging micro-welding spot

A technology for electronic packaging and evaluation methods, applied in welding equipment, metal processing equipment, material thermal development and other directions, can solve problems such as limited temperature gradient range, inability to effectively evaluate the reliability of electronic packaging micro-solder joints, and achieve consistent thickness and preparation. Stable and reliable, good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

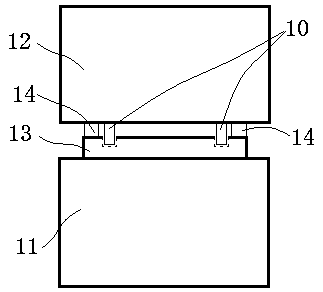

[0029] Embodiment 1, a method for evaluating the reliability of micro-solder joints in electronic packaging, which includes the following steps.

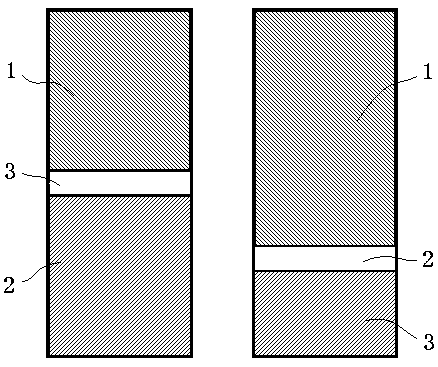

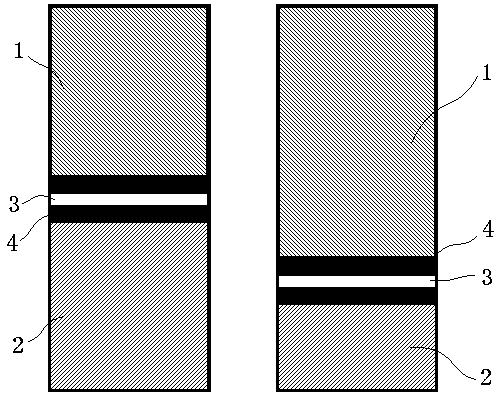

[0030] 1) Select the first metal plate and the second metal plate whose material is pure Co, see figure 2 , the thickness of the first metal plate 1 is 7.2 mm, and the thickness of the second metal plate 2 is 3.6 mm. It should be noted here that the thickness of the first metal plate 1 and the second metal plate 2 can also be the same, and the second The thickness of the second metal plate 2 is set to be smaller than the first metal plate 1, so that the micro-soldering point is as close as possible to the hot end, has higher capacity, and is more prone to thermal migration; then the first metal plate 1 and the second metal plate 2 Apply flux to the opposite welding surface, align the welding surfaces of the first metal plate 1 and the second metal plate 2, and use a mica sheet with a thickness of 70 μm to separate the first metal p...

Embodiment 2

[0035] Embodiment 2, a method for evaluating the reliability of micro-solder joints in electronic packaging, which includes the following steps.

[0036] 1) Select the first metal plate and the second metal plate made of pure Cu, the thickness of the first metal plate is 7.2mm, and the thickness of the second metal plate is 3.6mm, and then use electroplating, electrodeposition or sputtering on the Prepare the first metal layer and the second metal layer whose material is Co-3.5at%P on the first metal plate and the second metal plate, and then coat flux on the opposite welding surface of the first metal layer and the second metal plate Align the welding surfaces of the first metal layer and the second metal layer, separate the first metal layer and the second metal layer with a mica sheet with a thickness of 70 μm, and perform dip soldering at a temperature of 320 ° C. The material is pure Sn, an intermetallic compound is formed at the contact point between the first metal laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weld width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com