Rock breakage gas generator and gas generating agent rock breaking method

A technology of gas generator and gas generating agent, which is applied in blasting, blasting cylinder, weapon accessories and other directions, can solve the problems of complex safety construction requirements, and achieve the effect of simple and easy construction operation, high safety and safe construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

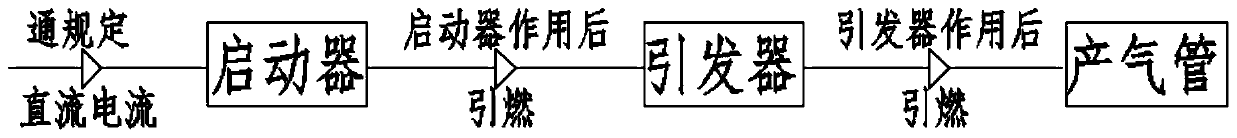

[0049] see figure 1 , the embodiment of the present invention provides a rock-breaking gas generator, including a gas production pipe 100 , an initiator 200 and a starter 300 that are independent and detachable from each other. The gas production pipe 100, the initiator 200 and the starter 300 are assembled to form the whole rock-breaking gas generator. Such as figure 2 As shown, the DC starting current generated by the external electric detonator starts the starting head through the conductive lead, ignites the first gas generating agent in the starter, and the energy generated ignites the second gas generating agent in the initiator. After the two-stage ignition, the energy is amplified, transmitted to the gas production pipe, and finally ignites a large amount of third gas generating agent in the gas production pipe.

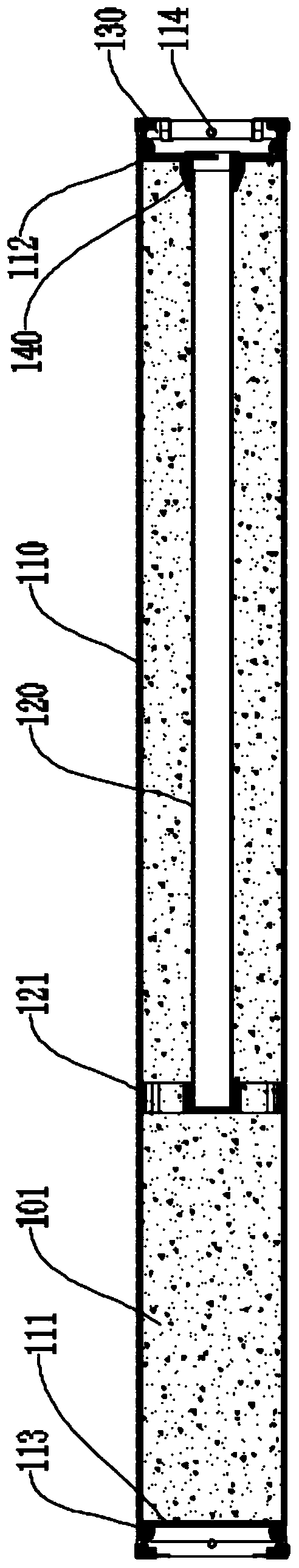

[0050] Such as image 3 As shown, the gas production tube 100 includes an outer cylinder 110 and an inner cylinder 120 supported in the outer cylinder 11...

Embodiment 2

[0084] The embodiment of the present invention provides a rock-breaking gas generator. Its realization principle and technical effects are the same as those of Embodiment 1. For a brief description, reference can be made to the corresponding content in Embodiment 1 for what is not mentioned in this embodiment.

[0085] The rock-breaking gas generator obtained through the above design can basically meet the use requirements of rock-breaking products, but in line with the purpose of further improving its functions, the designer has made further improvements to the device.

[0086] see Figure 8 and Figure 9 , the rock-breaking gas generator includes a gas production pipe 100 that is independent and detachable, an initiator 200 , an initiator 300 , and a fire transmission / insulation safety assembly 500 arranged between the initiator 300 and the initiator 200 .

[0087] The transmission / fire protection safety assembly 500 includes a pressure sensitive valve 510 and two hollow tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com