Cast-in-place superposed formwork integrated structure of prefabricated building and construction method

A prefabricated and formwork component technology, which is applied in building components, building structures, buildings, etc., can solve the problems of unsatisfactory ductility, poor sound insulation and heat resistance, joint bearing capacity, stiffness and ductility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

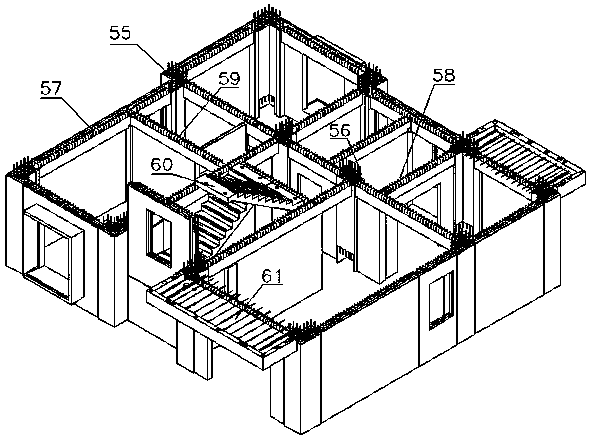

[0094] Embodiment 1 is an integrated structure of cast-in-place laminated formwork for a prefabricated building, which includes a shear wall member 55, a laminated column member 56, a laminated beam member 59, a laminated plate member, an inner partition wall member 58, Peripheral parapet elements 57, staircase elements 60 and balcony elements 61;

[0095] The above-mentioned components are connected by sleeve grouting and then poured into concrete from the grouting hole to connect as a whole, thus forming an integrated structure of cast-in-place laminated formwork for the prefabricated building;

[0096] The composite column member 56 and the shear wall member 55 are connected by sleeve grouting, pressure sleeve or local ribbing;

[0097] The peripheral parapet wall member 57 is connected with the shear wall member 55 or the superimposed column member 56 by using a concealed column and local ribbing;

[0098] The vertical connection of the inner partition wall member 58 adop...

Embodiment 2

[0120] Embodiment 2 is a construction method of an integrated structure of cast-in-place laminated formwork for a prefabricated building:

[0121] The construction method is mainly divided into two parts: the production and processing method of formwork components and the construction and installation method of formwork components;

[0122] Production and processing methods of main formwork components:

[0123] 1. After the completion of various formwork component drawings, deepen the formwork component drawings into formwork processing drawings, including the exact size of each formwork component section, configuration of skeleton steel bars or steel wires, specifications, models, etc. of insulation boards and other materials. The location and size of the prefabricated pipeline, the material specifications and shape details of the embedded parts, the location and size of the hook, the location and fixing parts, and the information characteristics of the hole through the wall; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com