Preparation method of high-end nanometer calcium carbonate for butyl rubber products

A nano-calcium carbonate, butyl rubber technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, chemical instruments and methods, etc. The particles are finer and more uniform, the uniformity is guaranteed, and the effect of low pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

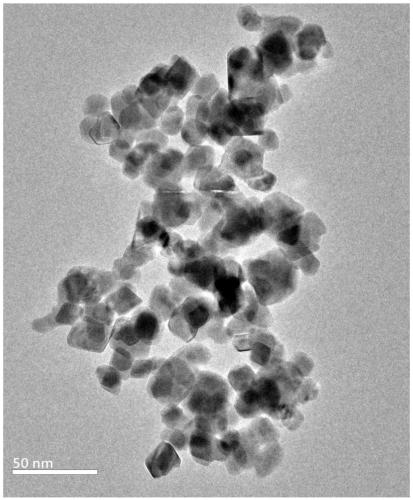

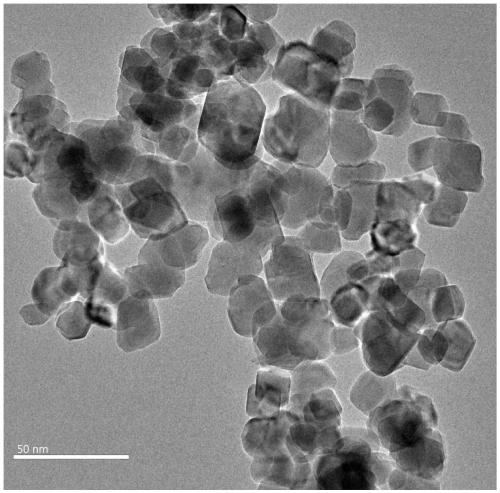

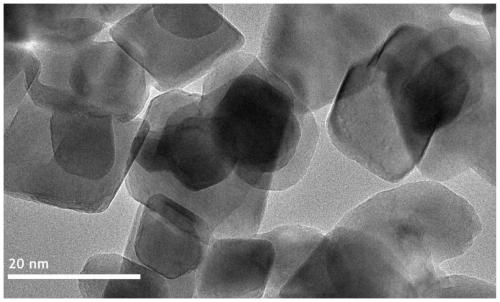

Image

Examples

Embodiment 1

[0053] A kind of preparation method of high-end nanometer calcium carbonate for butyl rubber product, comprises the following steps,

[0054] Step 1. Mix quicklime with an activity of 410ml and a whiteness of 95.0 with digested water at a temperature of 75°C in a mass ratio of 1:7, and then carry out a digestion reaction to obtain a coarse slurry of calcium hydroxide and lime activity. The purity and reactivity of calcium hydroxide are guaranteed due to the use of ultra-high activity lime for digestion. According to the thermodynamics and kinetics of the digestion reaction, reasonable water temperature and reasonable gray water are used. The reaction ratio ensures the thoroughness of the digestion reaction;

[0055] Step 2: Pass the coarse calcium hydroxide slurry through 300-mesh and 400-mesh vibrating screens to remove impurities, and then pass through five-stage suspension separators connected in series to obtain fine calcium hydroxide pulp. The sieve is used for sieving a...

Embodiment 2

[0067] A kind of preparation method of high-end nanometer calcium carbonate for butyl rubber product, comprises the following steps,

[0068] Step 1. Mix quicklime with an activity of 405ml and a whiteness of 95.5 with digested water at a temperature of 75°C in a mass ratio of 1:8, and then carry out a digestion reaction to obtain a coarse slurry of calcium hydroxide and lime activity. The purity and reactivity of calcium hydroxide are guaranteed due to the use of ultra-high activity lime for digestion. According to the thermodynamics and kinetics of the digestion reaction, reasonable water temperature and reasonable gray water are used. The reaction ratio ensures the thoroughness of the digestion reaction;

[0069] Step 2: Pass the coarse calcium hydroxide slurry through 300-mesh and 400-mesh vibrating screens to remove impurities, and then pass through five-stage suspension separators connected in series to obtain fine calcium hydroxide pulp. The sieve is used for sieving a...

Embodiment 3

[0081] A kind of preparation method of high-end nanometer calcium carbonate for butyl rubber product, comprises the following steps,

[0082] Step 1. Mix quicklime with an activity of 400ml and a whiteness of 94.5 with digested water at a temperature of 73°C in a ratio of 1:9 by mass, and then carry out a digestion reaction to obtain a coarse slurry of calcium hydroxide and lime activity. The purity and reactivity of calcium hydroxide are guaranteed due to the use of ultra-high activity lime for digestion. According to the thermodynamics and kinetics of the digestion reaction, reasonable water temperature and reasonable gray water are used. The reaction ratio ensures the thoroughness of the digestion reaction;

[0083] Step 2. Pass the coarse calcium hydroxide slurry through 300-mesh and 400-mesh vibrating screens to remove impurities, and then pass through five-stage suspension separators connected in series to obtain fine calcium hydroxide slurry. Due to the adoption of two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com