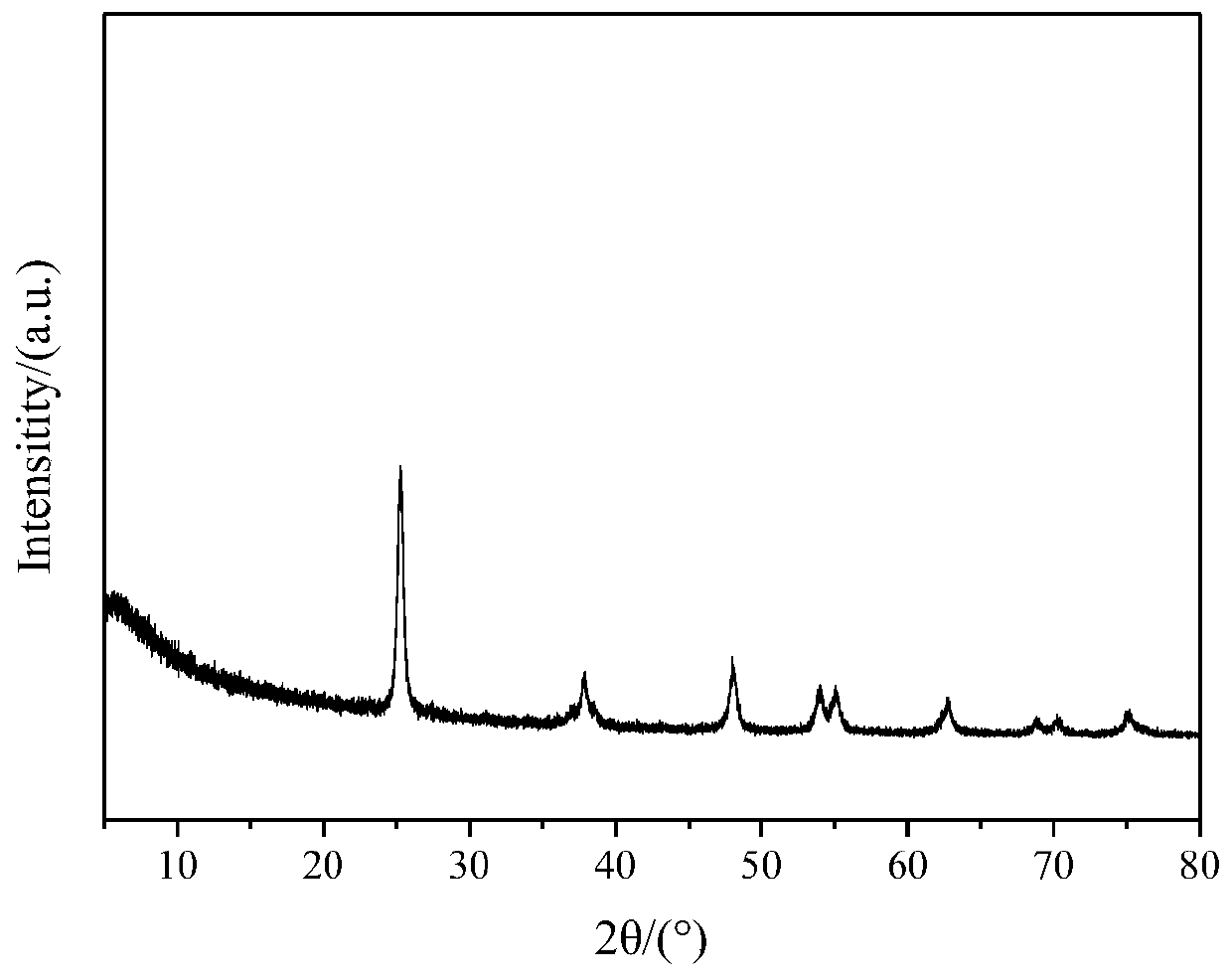

Method for preparing iron-doped graphene oxide titanium oxide nanocomposite modified micro-filtration membrane

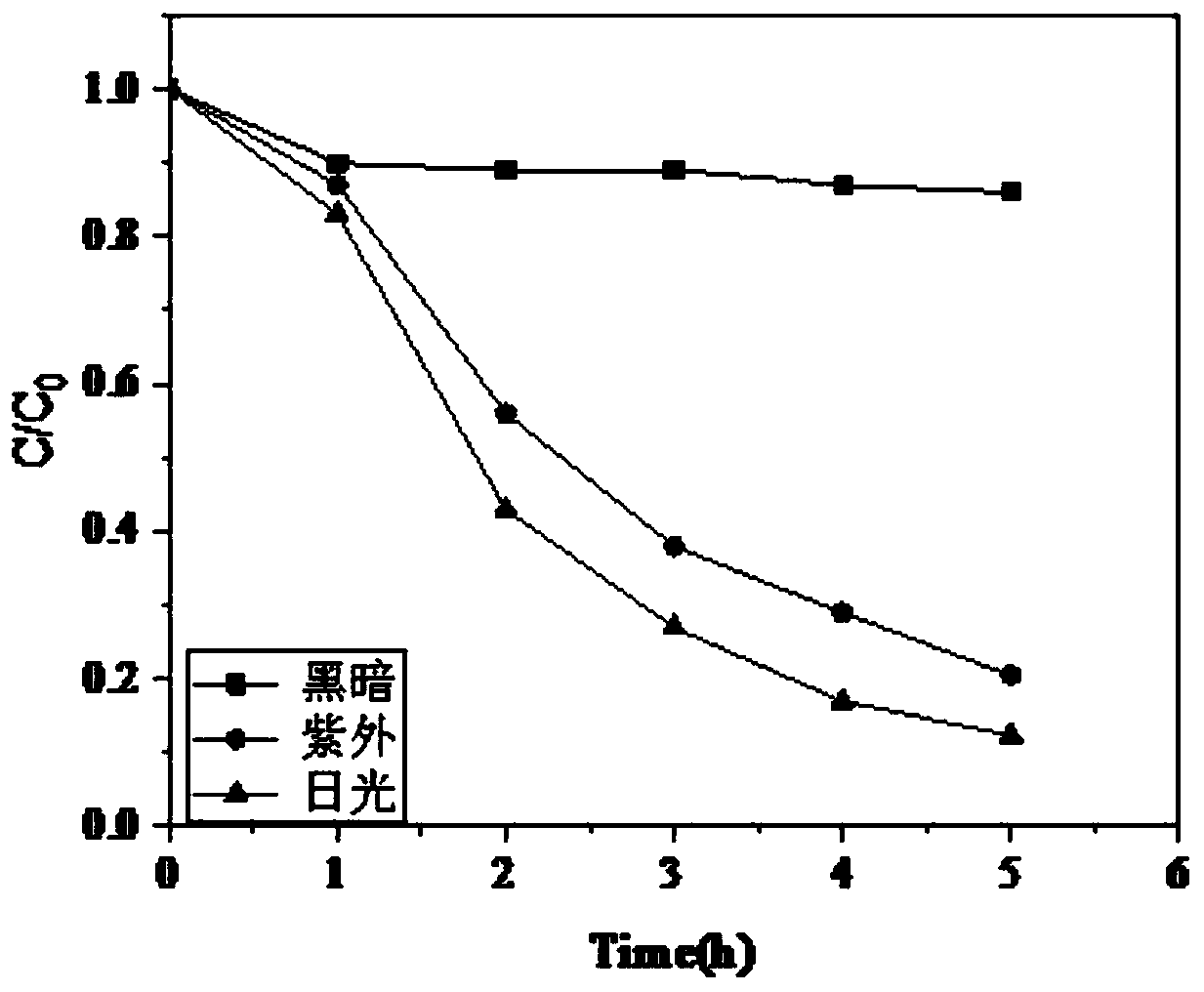

A nanocomposite material, titanium dioxide technology, applied in the field of photocatalytic materials, can solve the problem of low photocatalytic activity, achieve high photocatalytic activity, reduce water contact angle, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the iron-doped graphene oxide titanium dioxide nanocomposite material modified microfiltration membrane of the present embodiment is as follows:

[0029] (1) GO nanosheets were synthesized by graphite-modified Hummers method. The synthesis process involves adding graphite in KMnO 4 , H 2 SO 4 and NaNO 3 Oxidation in the mixture, the mixture was filtered to collect the solid particles (i.e., graphite oxide), the solids were washed in deionized water by three cycles of resuspension and centrifugation to remove chemical residues, and the GO particle suspension was sonicated using an ultrasonic cleaner to remove the oxidized particles. Graphite was exfoliated into GO nanosheets, and finally any unexfoliated graphite residue was removed by centrifugation to obtain a pure GO nanosheet suspension, which was freeze-dried to obtain GO powder;

[0030] (2) Preparation of Fe-TiO by sol-gel method 2 nanoparticles. First, 10 mL of tetrabutyl titanate ...

Embodiment 2

[0037] (1) GO nanosheets were synthesized by graphite-modified Hummers method. The synthesis process involves adding graphite in KMnO 4 , H 2 SO 4 and NaNO 3 Oxidation in the mixture, the mixture was filtered to collect the solid particles (i.e., graphite oxide), the solids were washed in deionized water by three cycles of resuspension and centrifugation to remove chemical residues, and the GO particle suspension was sonicated using an ultrasonic cleaner to remove the oxidized particles. Graphite was exfoliated into GO nanosheets, and finally any unexfoliated graphite residue was removed by centrifugation to obtain a pure GO nanosheet suspension, which was freeze-dried to obtain GO powder;

[0038] (2) Preparation of Fe-TiO by sol-gel method 2 nanoparticles. First, 10 mL of tetrabutyl titanate was added to 20 mL of absolute ethanol to form solution A. Solution B is the addition of FeCl 3 A mixture of 10 mL of absolute ethanol, 15 mL of deionized water and 4.5 mL of acet...

Embodiment 3

[0043] (1) GO nanosheets were synthesized by graphite-modified Hummers method. The synthesis process involves adding graphite in KMnO 4 , H 2 SO 4 and NaNO 3 Oxidation in the mixture, the mixture was filtered to collect the solid particles (i.e., graphite oxide), the solids were washed in deionized water by three cycles of resuspension and centrifugation to remove chemical residues, and the GO particle suspension was sonicated using an ultrasonic cleaner to remove the oxidized particles. Graphite was exfoliated into GO nanosheets, and finally any unexfoliated graphite residue was removed by centrifugation to obtain a pure GO nanosheet suspension, which was freeze-dried to obtain GO powder;

[0044] (2) Preparation of Fe-TiO by sol-gel method 2 nanoparticles. First, 10 mL of tetrabutyl titanate was added to 20 mL of absolute ethanol to form solution A. Solution B is the addition of FeCl 3 A mixture of 10 mL of absolute ethanol, 15 mL of deionized water and 4.5 mL of acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com