Preparation device and method for nuclear track membrane

A technology for nuclear pore membranes and thin films, which is applied in the field of devices for preparing nuclear pore membranes. It can solve the problems of hindering etching, poor uniformity and fluidity of etching solution, and uneven distribution, so as to improve uniformity and fluidity, and improve etching. The effect of uniformity and micropore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

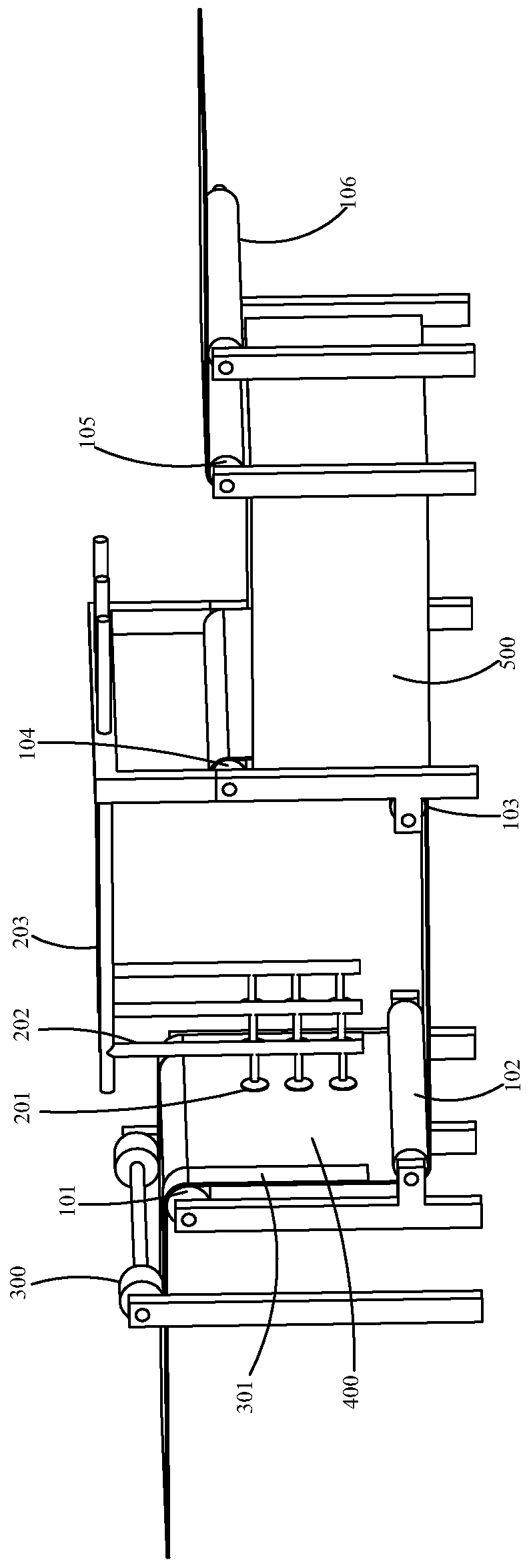

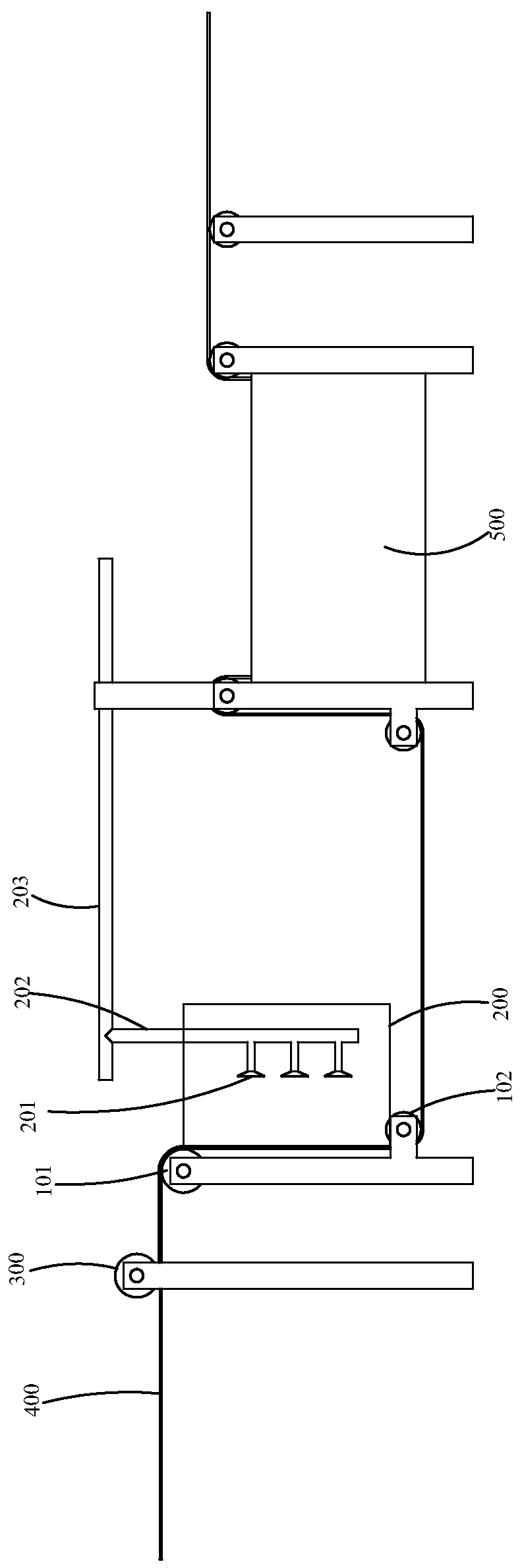

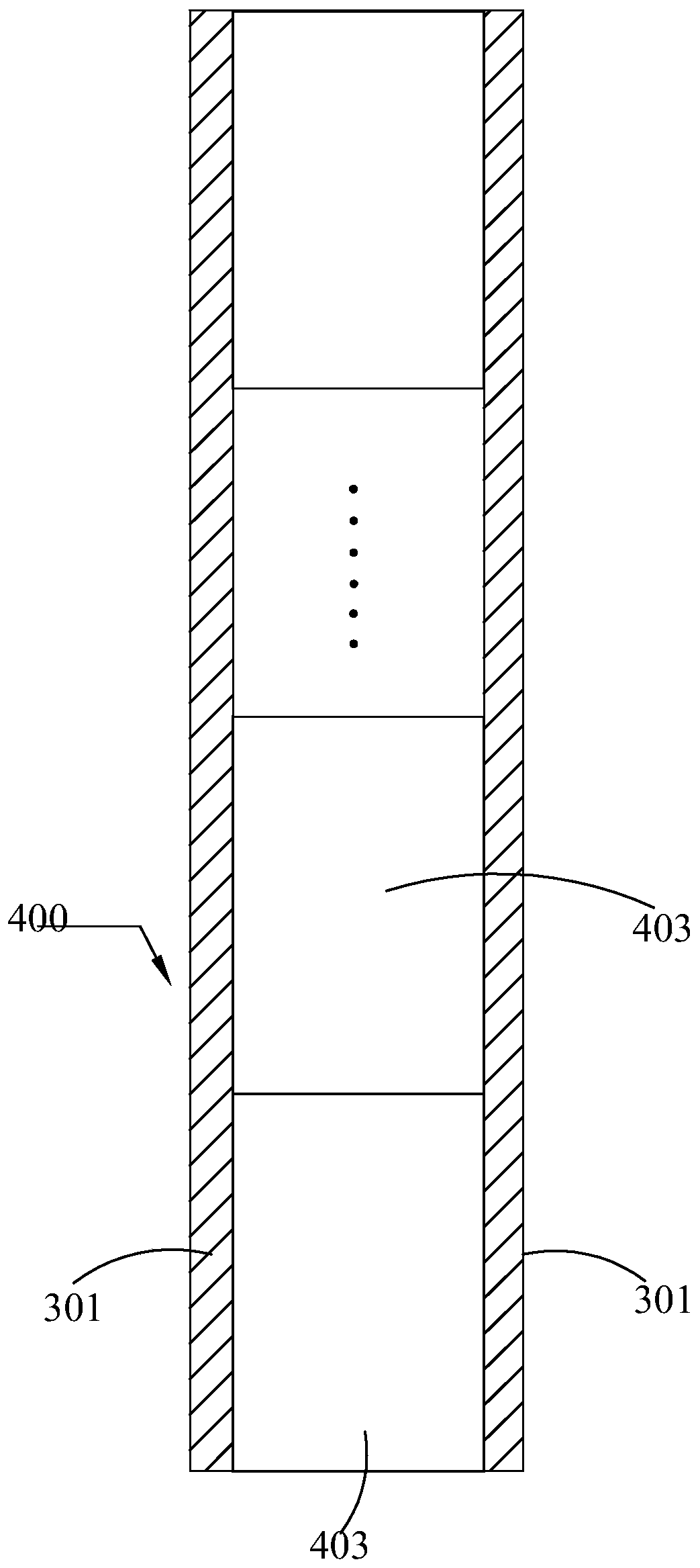

[0047] see figure 1 and combine figure 2, The nuclear pore membrane preparation device in the first embodiment includes: a sealing structure, a transmission component and a spraying area 200 . The sealing structure here adopts the pressing part 300 . The conveying part is used for conveying the original film 400 to be etched. Here, before entering the preparation device of the nuclear pore membrane, the pristine thin film 400 may be irradiated with heavy ions by using, but not limited to, heavy ions provided by a high-energy accelerator. Here, the original film 400 can be an organic film or an inorganic film. The original film 400 requires a certain hardness to withstand heavy ion radiation. Preferably, PET, PC, PP, PI, mica sheet or glass sheet can be used. films of other materials. The heavy ions provided by the high energy accelerator can be Kr, Ar, Xe, Bi ions. The energy of ion irradiation can be 5~50MeV / u, and the implantation meter of irradiation can be 1×10 4 up...

Embodiment 2

[0069] The difference between the preparation device of the nuclear pore membrane of the present embodiment 2 and the preparation device of the nuclear pore membrane of the embodiment 1 is that the setting of the spray area and the setting of the sealing mechanism are different, so that the sealing method and the sealing release method of the original film are different. . In addition, there is no corrosion solution tank in the second embodiment.

[0070] Specifically, see Figure 5 with 6 , In the second embodiment, the spray area 200 is provided with a vacuum adsorption part 700 and a sealing mechanism; the surface of the vacuum adsorption part 700 is provided with a plurality of suction holes. Specifically, the sealing mechanism is jointly composed of a vacuum adsorption component 700 and a flexible shielding component 301 . The joint sealing process between the two will be described in detail later. At the same time, the vacuum suction component 700 is also used to abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com