Additive containing electrolytes for high energy rechargeable metal anode batteries

A rechargeable, electrolyte-based technology for electrochemical cells that can address issues that have failed to gain commercial traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] We describe a general procedure for the preparation of novel electrolyte solutions suitable for commercially viable lithium metal batteries, the components of which are selected from the embodiments herein. Both the concentration of lithium salt and the relative ratio between solvents or additives can be varied according to individual needs. Electrolyte solutions were prepared by dissolving one or a combination of lithium salts selected from Table I in a mixture of one part EC and two parts DMC by volume in an anhydrous and oxygen-free environment. The total concentration of lithium cations will occur in the range of 0.25M to 5M. A single additive or a combination of additives was selected from Table II and dissolved in the electrolyte solution between 0 wt% and 10 wt%. Dissolution occurs within 1-2 hours, and the electrolyte may or may not be filtered prior to use.

[0100] Intercalation cathodes used in conjunction with electrolytes according to the invention prefer...

Embodiment 2

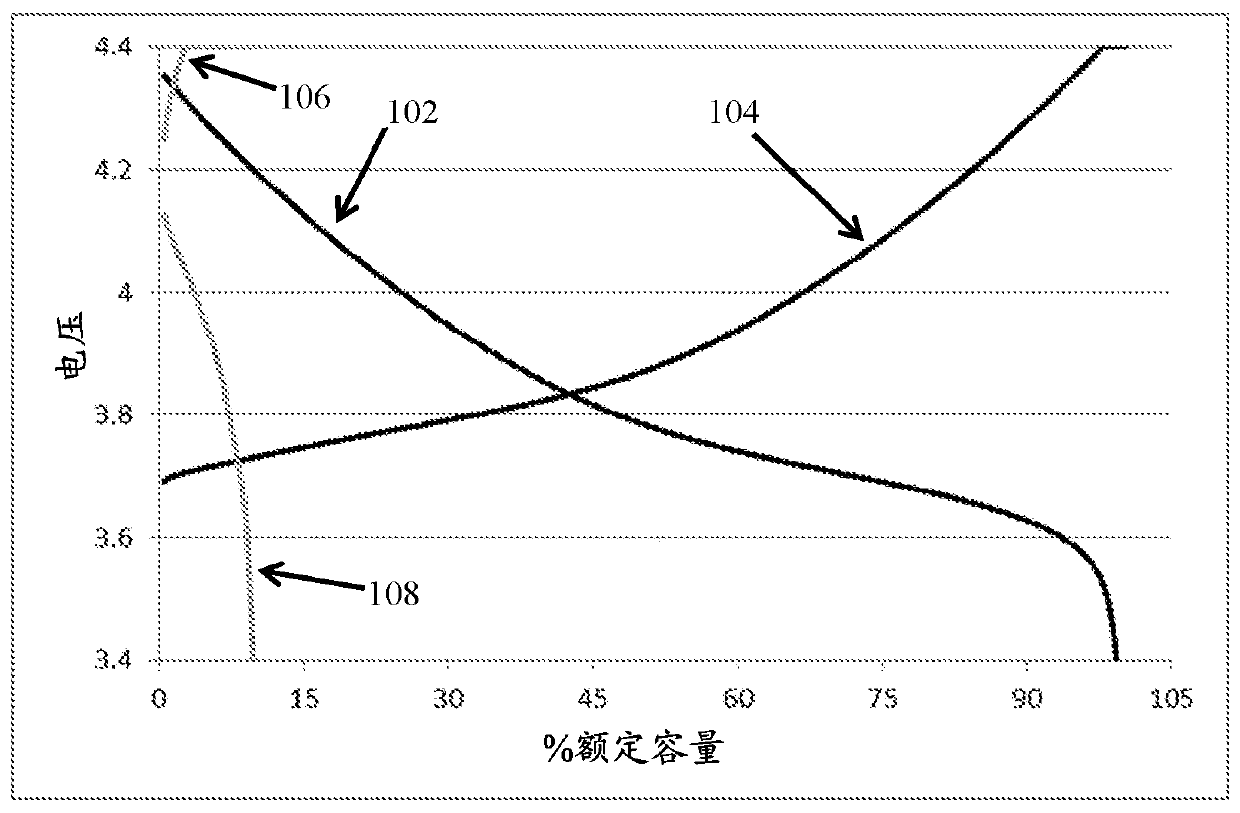

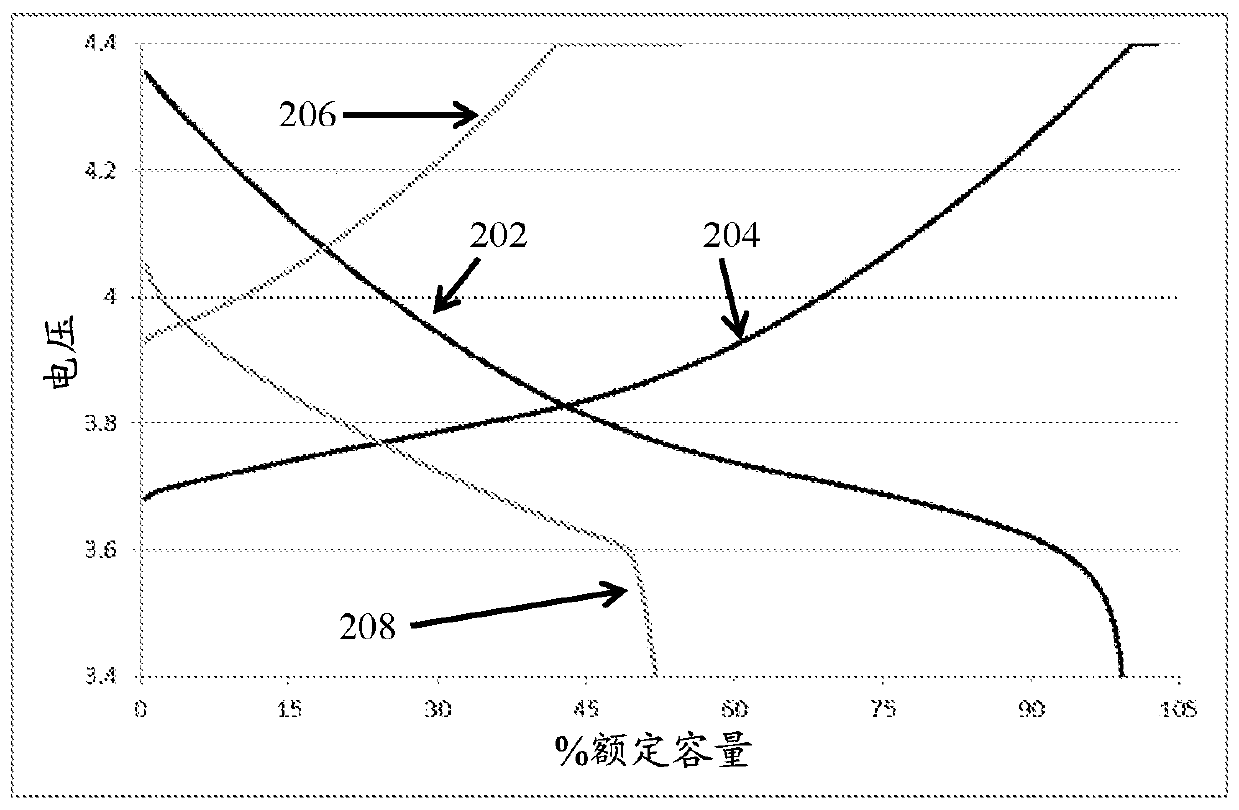

[0112] figure 1 Depicted are Cycle 1 (black) and Cycle 60 ( Gray) is the percentage of the voltage relative to the rated capacity. This is a zero excess lithium cell (ie N / P figure 2 Depicted are voltages as a percentage of rated capacity for comparative cells containing those electrolyte additives disclosed herein. Cycle 1 (black) and cycle 60 (gray) of a cell comprising a lithium transition metal oxide cathode, a lithium metal anode, and 0.85M lithium bis(oxalato)borate with an additive comprising (V / V) 1 wt% lauryl isocyanate in electrolyte. This is a zero excess lithium cell (ie N / P < 1, all lithium in the cell as constructed is present in the cathode). Cells were cycled at room temperature with constant current discharge at 1C-rate to 100% depth of discharge. It is apparent from the graph that the capacity retention rate at 60 cycles is about 50% of the value achieved at 1 discharge. Modification of the electrolyte by addition of 1 wt% lauryl isocyanate resulted in ...

Embodiment 3

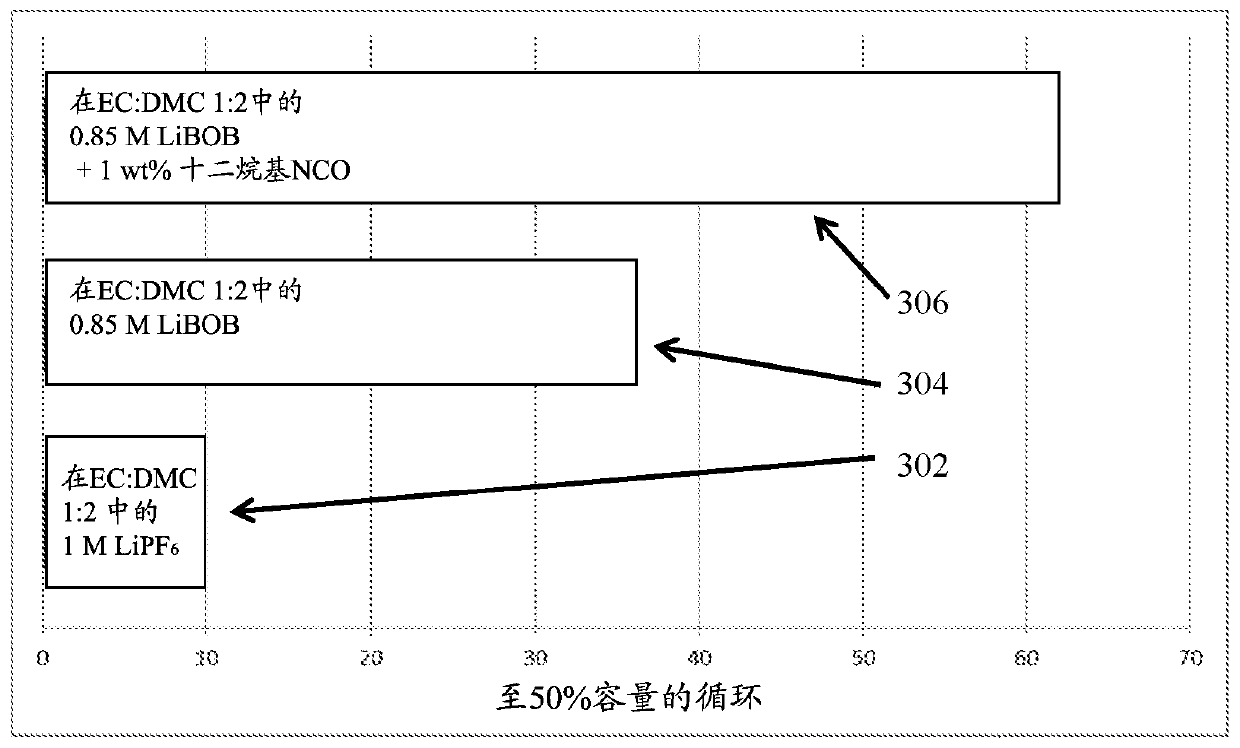

[0114] Three cells comprising lithium transition metal oxide cathodes, lithium metal anodes, electrolytes, and porous, electron-resistant separators were cycled at room temperature with constant current discharge at 1C-rate to 100% depth of discharge. image 3 The number of charge-discharge cycles to 50% rated capacity is depicted for each of the three cells. The electrolyte in one cell contains 1M LiPF in EC:DMC1:2 (v / v) 6 , while the electrolyte in the second cell contained 0.85M LiBOB in EC:DMC1:2 (v / v), and the third cell contained 0.85M LiBOB and additives in EC:DMC1:2 (v / v) 1 wt% lauryl isocyanate. 1M LiPF in EC:DMC1:2 (v / v) 6 It takes only 10 cycles to decay to 50% capacity, while the electrolyte containing 0.85M LiBOB in EC:DMC1:2 (v / v) can achieve 50% capacity retention at 36 cycles, and contains electrolyte The additives, namely 0.85M LiBOB and additive 1wt% dodecyl isocyanate in EC:DMC 1:2 (v / v), reached the capacity retention mark of 50% at 62 cycles. It is cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com