Method of manufacturing of a foam-formed cellulosic fibre material, sheet and laminated packaging material

A technology of cellulose fibers and packaging materials, applied in the field of laminated packaging materials, packaging containers, main sheets or molded products, and low-density cellulose fiber materials formed by foam, which can solve deterioration, low density, and increase cellulose density. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

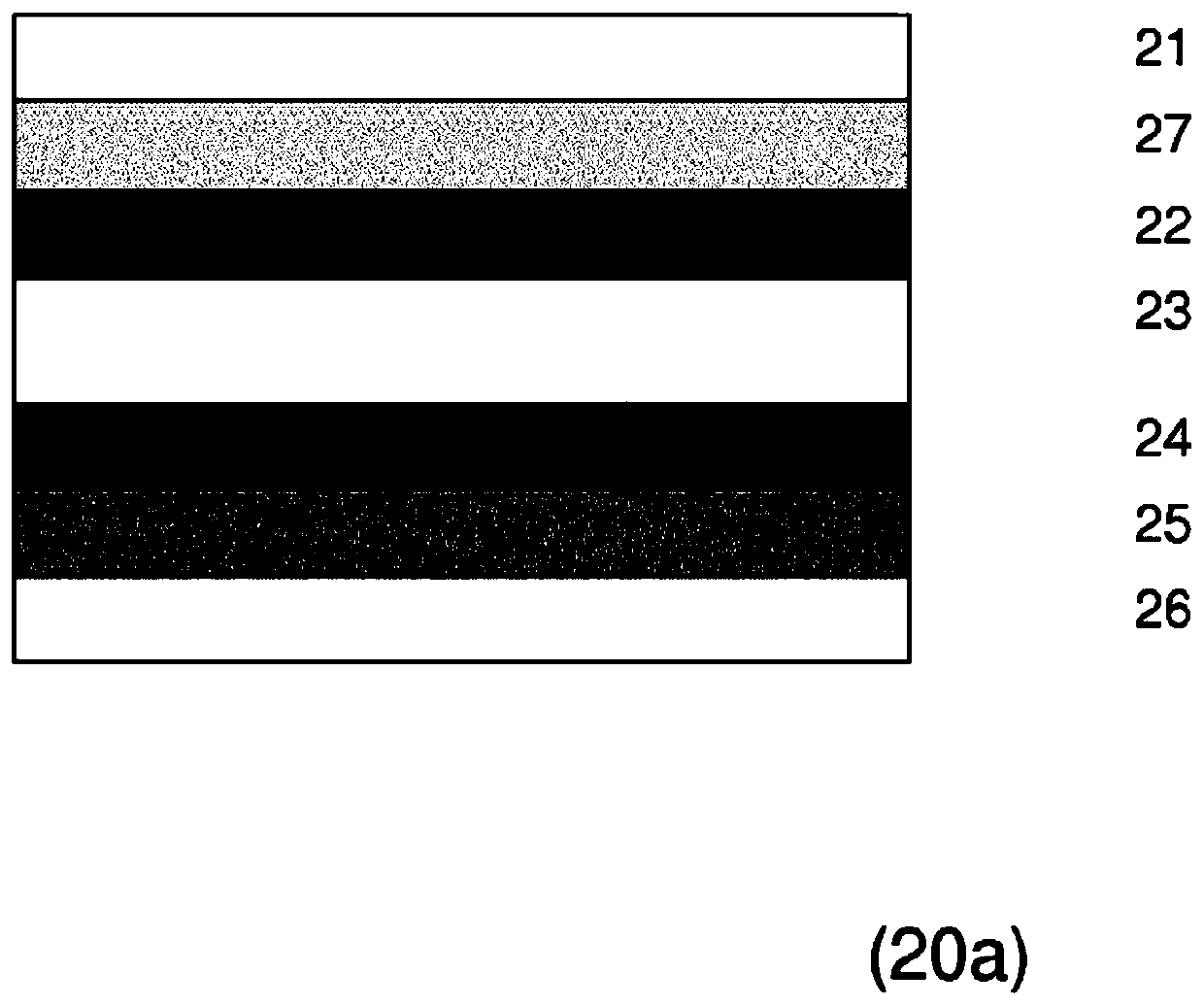

[0222] Modified cellulose pulp is prepared from unmodified lignocellulosic fiber pulp by oxidation of a fraction of the fibers in suspension to dialdehyde cellulose, based on the initial number of oxidizable C2-C3 bonds, the degree of conversion to about 30%, the dialdehyde cellulose is then reduced to diol cellulose. The average diameter of the cellulose fibers is at least 1 μm. The fibers of the present disclosure typically have an average diameter of at least 5 μm, such as at least 8 μm, such as at least 12 μm. The average length of the fibers of the invention is preferably at least 0.3 mm, eg 0.3 mm to 4 mm. However, any fiber length is conceivable as long as the fiber foam can be produced, for example up to 50 mm. The fibers of the present disclosure are preferably lignocellulosic in origin. The degree of conversion of cellulose to dialdehyde cellulose can be determined using the "carbonyl content determination" method described below. The fiber suspension used in the...

Embodiment 2

[0234] A blend of chemithermomechanical pulp (CTMP, freeness 600 ml) prepared in Example 1 similar to modified pulp and / or highly refined hardwood pulp was mixed and foamed. Add retention chemicals such as cationic starch (CS) and retention aid (RA) to the foam composition in the following order: CS at 0 seconds and RA 1 at 5 seconds (cationic polyacrylamide 0.4 kg / t) , at 10 seconds add RA2 (particles, from Hercules' " SP7200", 0.4kg / t"), and stop mixing at 15 seconds. Finally, the pulp foam is moved to a sheet mold and made into a sheet.

[0235] The results on Scott Bond delamination strength and tensile strain show the same improvement trend as Example 1. Therefore, the effect of adding modified cellulose containing diol cellulose was still significant regardless of the amount of starch and other retention additives added.

[0236] Figure 10 The relationship between delamination strength and the content of diol-modified cellulose is shown, and compared with the resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com