Composite nano cold cathode structure with high stability electron emission and preparation method

A technology of electron emission and cold cathode, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc. It can solve problems such as melting point limitation and electric field change, and achieve low turn-on electric field, simple structure, and high stability. The effect of electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

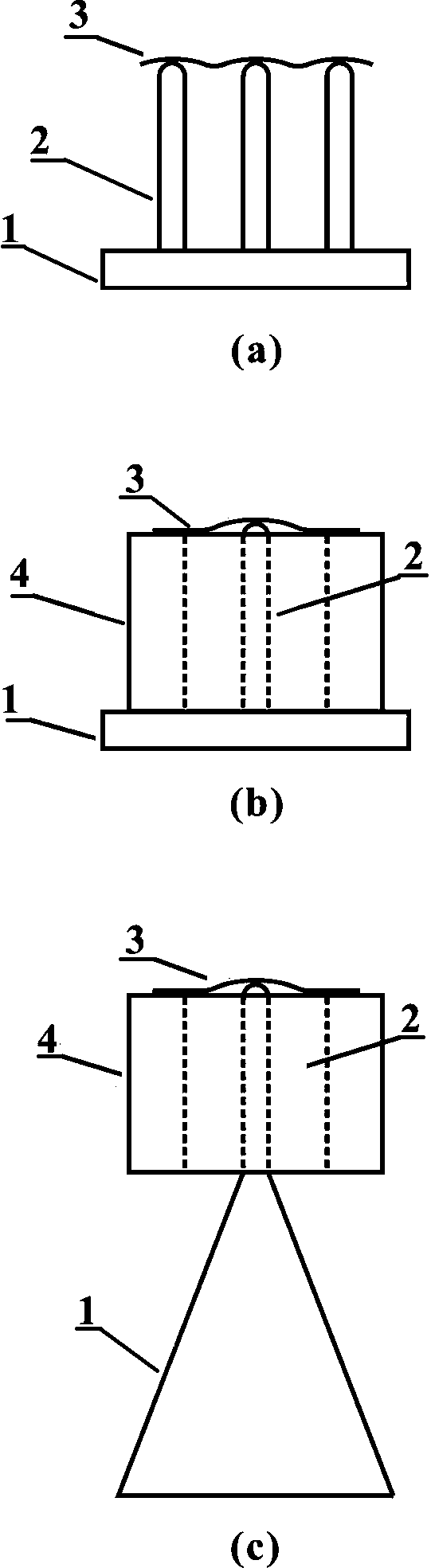

[0035] Such as figure 1 As shown, the structural schematic diagrams of three composite low-dimensional nano-cold cathodes using nanowires as low-dimensional cold cathode materials on the basis of different substrates are given.

[0036] The basic structure of the cold cathode includes a substrate 1 , a low-dimensional nano cold cathode 2 , a two-dimensional film material 3 and a support structure 4 .

[0037] figure 1 In a, the substrate 1 is a planar structure, and the supporting structure is the low-dimensional nano cold cathode array itself; figure 1 In b, the substrate 1 is a planar structure, and the supporting structure is an integrated small hole in the insulating layer; figure 1 In c, the substrate 1 is a tapered structure, and the supporting structure is a separated ceramic mesh / copper mesh.

Embodiment 2

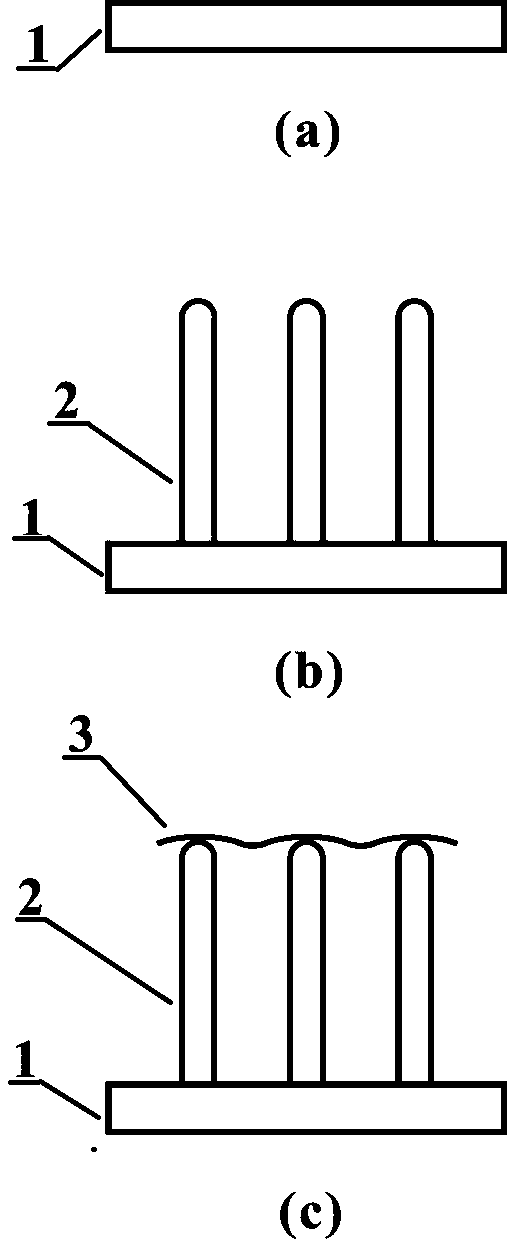

[0039] based on figure 1 Schematic diagram of the fabrication process of the composite nano-cold cathode structure.

[0040] Such as figure 2 as shown, figure 2 given in Example 1 figure 1 Fabrication flowchart of the composite nano-cold cathode structure in a. First prepare a flat substrate 1 ( figure 2 a); Then, vertical and equal-height low-dimensional nano-cold cathodes 2 are prepared on it, and multiple low-dimensional nano-cold cathodes 2 form a low-dimensional nano-cold cathode array ( figure 2 b); Finally, the two-dimensional thin film material 3 is transferred to the low-dimensional nano cold cathode 2 ( figure 2 c). The equal-height low-dimensional nano-cold cathode ensures that the geometric curvature of the tip of the two-dimensional film material is smaller than that of the tip of the nanowire.

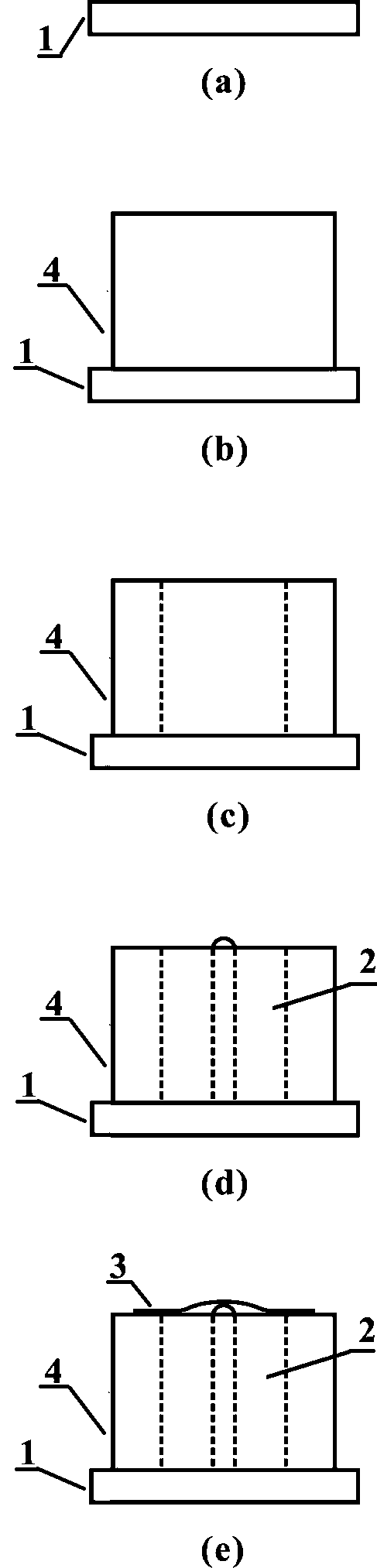

[0041] Such as image 3 as shown, image 3 given in Example 1 figure 1 Fabrication flowchart of the composite nano-cold cathode structure in b. First prep...

Embodiment 3

[0045] Figure 5 It is the simulation result of the surface energy band bending of the compound low-dimensional nano-cold cathode whose tip curvature of the two-dimensional thin film material is larger / smaller than that of the low-dimensional nanostructure tip.

[0046] Such as Figure 5 a and Figure 5 As shown in b, the schematic diagrams of the structures in which the geometric curvature of the tip of the two-dimensional thin film material is greater than and smaller than that of the nanowire tip are respectively listed. According to geometry, Figure 5 The 2D thin film material in b is in close contact with the nanowire tip at the tip, while Figure 5 The two-dimensional thin film material in a forms a suspended structure at the tip.

[0047] Figure 6 It is the simulation result of the surface energy band bending of single-layer tungsten diselenide films with different thicknesses under the applied electric field of 2.5 V / nm; Band bending under nm electric field. i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com