A valve body of a polyethylene ball valve

A technology of polyethylene ball and valve body, which is applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problems of leakage at the joint of the valve stem, easy damage to the valve stem, and reduction of extrusion force, etc., to achieve Effects of reducing material waste, reducing operating force, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

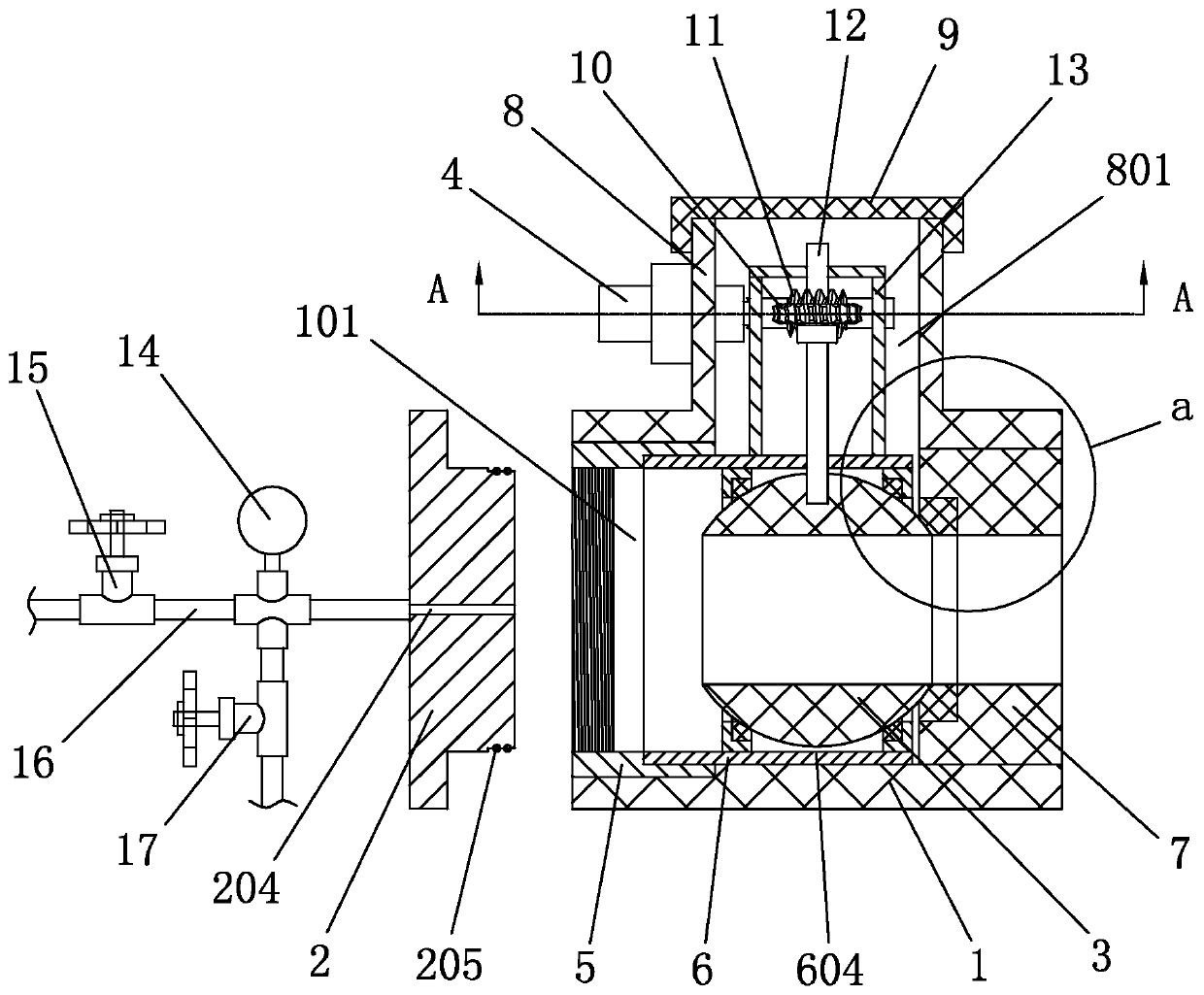

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

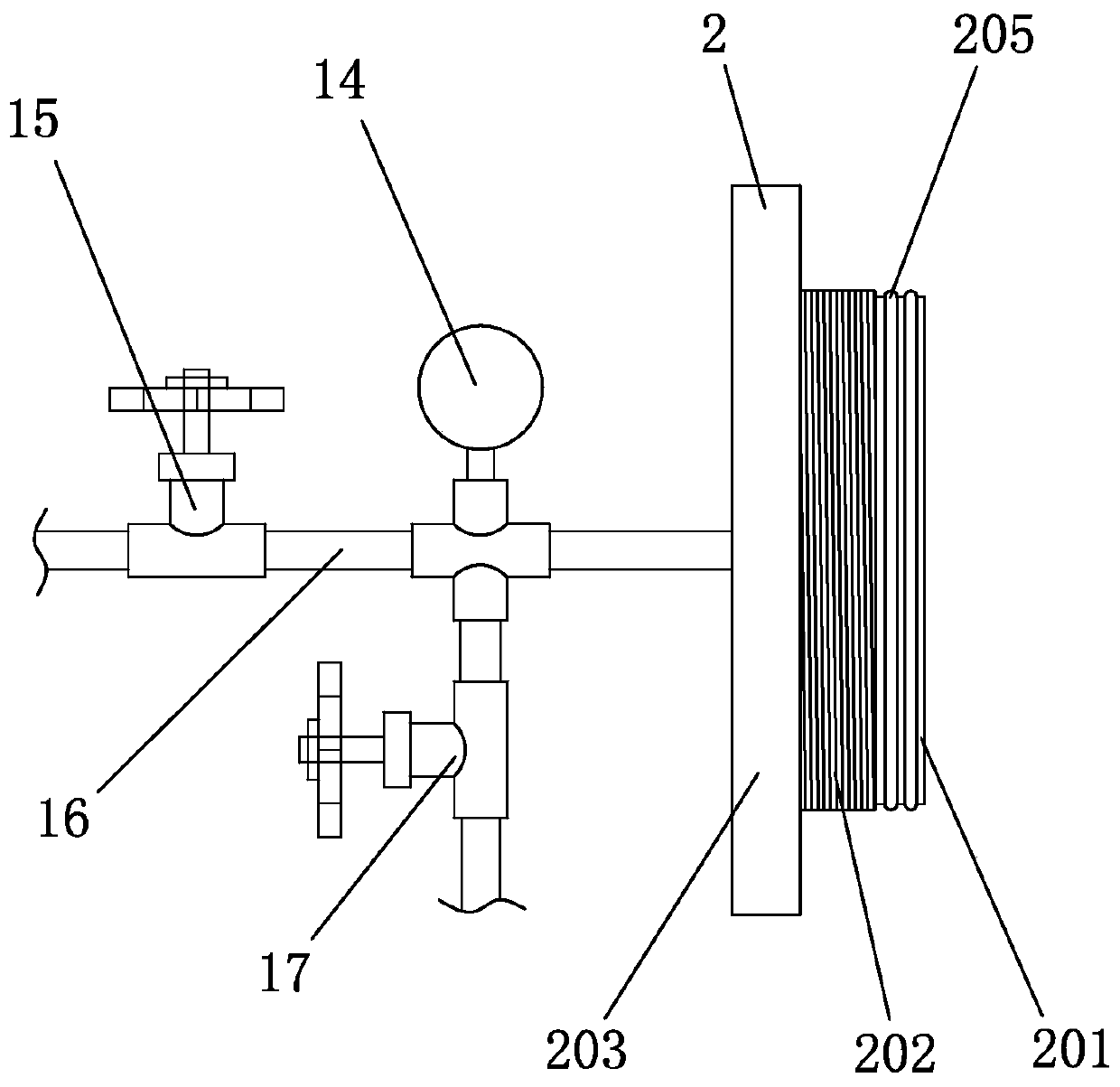

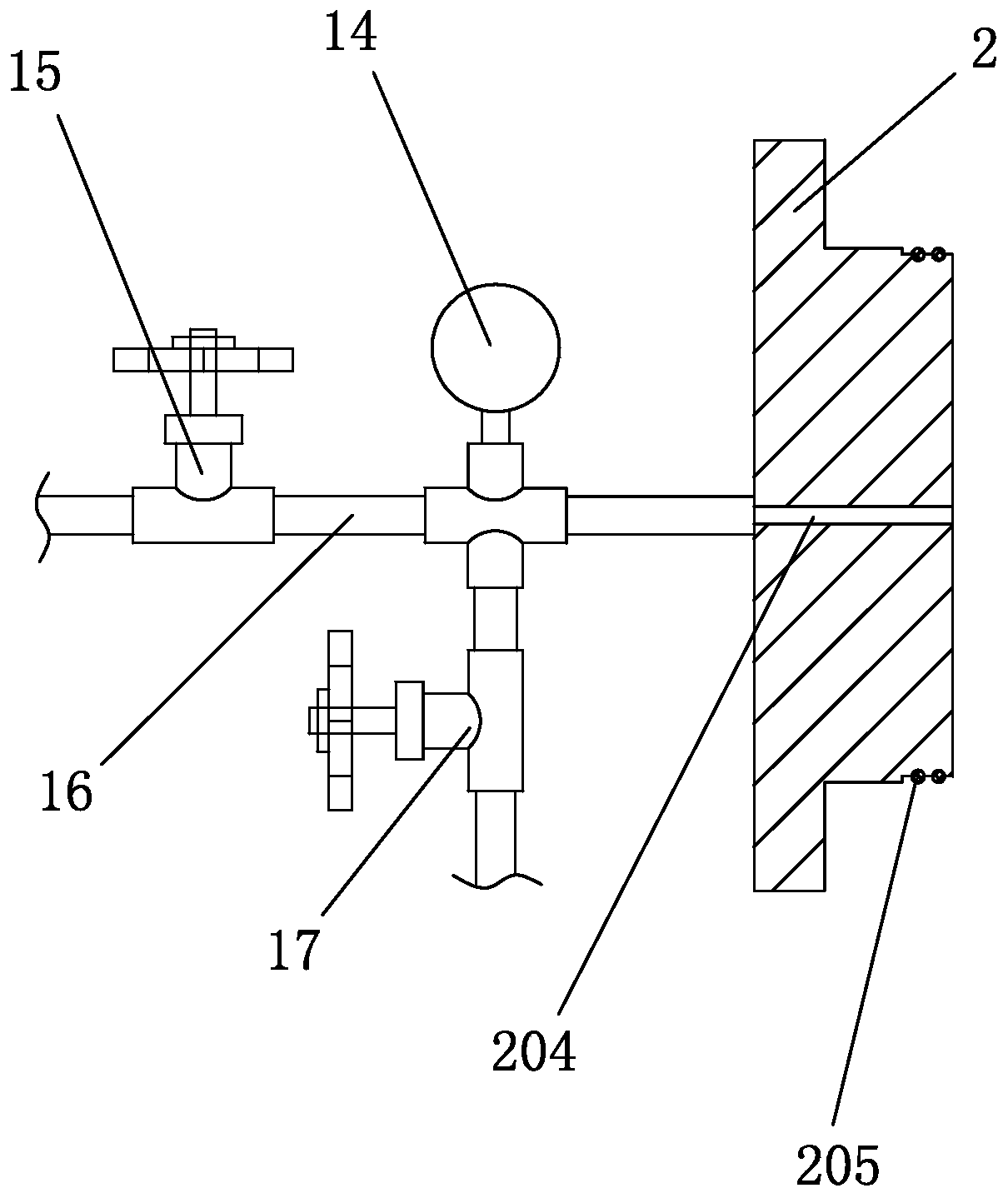

[0031] see Figure 1 to Figure 10 , the valve body of a polyethylene ball valve described in this embodiment at least includes a valve seat 1, a valve core 3 disposed in the valve seat 1 and a valve stem 4 for driving the valve core 3, and also includes a leak detection seal The cover 2 and the valve seat 1 are provided with a medium passage 101 , and the valve core 3 is provided in the medium passage 101 of the valve seat 1 .

[0032] One end of the medium channel 101 is embedded with a sliding sleeve 5, the sliding sleeve 5 is coaxially arranged with the medium channel 101, the outer wall of the sliding sleeve 5 is sealed and fixed with the inner wall of the medium channel 101, and the sliding sleeve 5 is provided with an internal thread section 503 and the smooth segment 504 , the internal thread segment 503 is located at the opening side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com