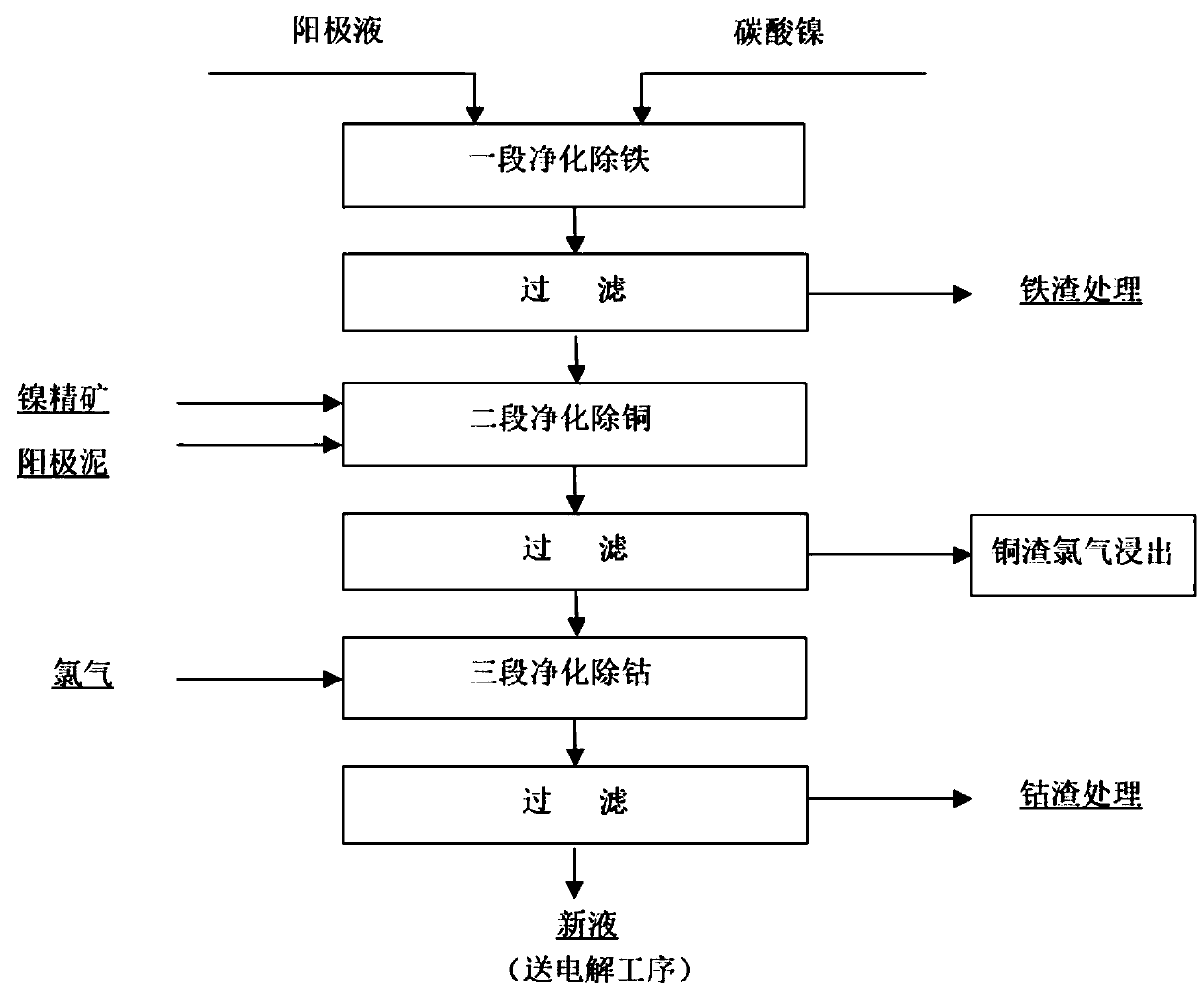

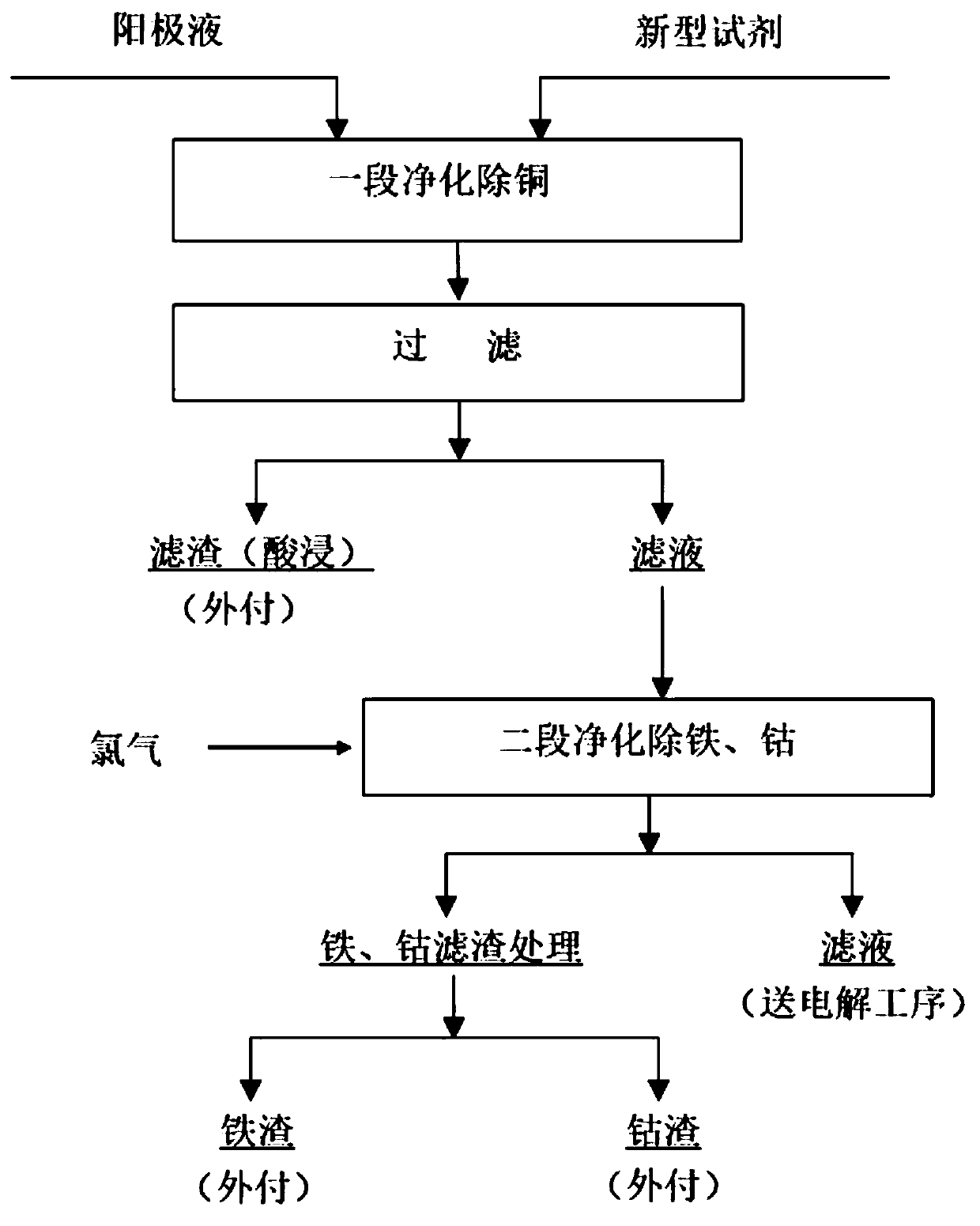

A two-stage impurity removal process for nickel sulfide soluble anode nickel electrolytic purification

A technology of nickel electrolysis and nickel sulfide, applied in the chemical industry, can solve the problems of low reaction efficiency, high production cost, long process flow, etc., and achieve the effect of reducing process flow, reducing production cost and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the alkaline copper removal reagent is as follows: first dilute the liquid caustic soda (sodium hydroxide) to 10-15%, then place the prepared liquid caustic soda on a heating plate and heat it to 95-100°C, add anode slime, Raise the pH of the solution to 10-12, stir and heat while adding anode slime, start adding nickel carbonate when the temperature reaches 100°C, and start timing. The reagent preparation time is 0.5-2h, and the prepared reagent is sampled for analysis.

[0029] The anode slime and nickel carbonate are added in a weight ratio of 4-6:1, and the liquid alkali solution and nickel carbonate slurry are mixed in a volume ratio of 30-50:1; the three reagents are mixed and reacted for about 3 hours at a temperature of 100°C.

[0030] The pH of the anolyte of the present invention is 0.5-2, and the flow rate is 200-300m 3 / h.

[0031] The amount of anode slime is calculated according to the amount of copper fed into the anolyte and a...

Embodiment 1

[0036] A preparation method of alkaline copper removal reagent is as follows: take 500g of anode slime (about 90% sulfur content), nickel carbonate volume 71mL (specific gravity 1.3-1.5g / cm 3 ) that weighs 95g, lye 2800mL, add 2800mL of lye diluted to 10% into a 5L beaker, then pass the diluted lye into steam and heat to 100°C, then add 500g of anode slime, stir and mix evenly, then add nickel carbonate The slurry solution was mixed and reacted for 2 hours until the color of the solution turned reddish brown, and the pH of the detection end point was 10, the stirring was stopped and the volume of the solution was recorded, and the sulfur content was analyzed by sampling.

[0037] A two-stage impurity removal process for electrolytic purification of nickel sulfide soluble anode nickel, specifically comprising the following steps:

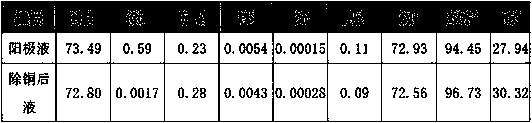

[0038]Step (1). One-stage anolyte copper removal: take the electrolytic anolyte and retain a sample for analysis (to save costs, it can be the same...

Embodiment 2

[0047] A preparation method of alkaline copper removal reagent is as follows: take 800g of anode slime, 110mL of nickel carbonate (specific gravity 1.3-1.5g / cm 3 ), that is, the volume is 145g, take 3800mL of liquid caustic soda diluted to 10%, add the liquid caustic soda into a 5L beaker, then heat the diluted liquid caustic soda to 100°C with steam, then add 800g of anode slime, stir and mix evenly, and finally add carbonic acid The nickel slurry solution was mixed and reacted for 2.5 hours until the color of the solution turned reddish brown, and the pH of the detection end point was 9. Stop stirring and record the volume of the solution, and take a sample to analyze the sulfur content.

[0048] A two-stage impurity removal process for electrolytic purification of nickel sulfide soluble anode nickel, specifically comprising the following steps:

[0049] Step (1). One-stage anolyte copper removal: take anolyte 2500mL, copper content 0.68g / L, copper content 1.7g, alkaline cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com