Soil remediation stabilizer prepared from high-iron tailings and preparation method and application thereof

A soil remediation and stabilizer technology, applied in the field of remediation of heavy metal polluted soil, can solve the problems of high cost of raw materials, cumbersome use process, complicated preparation process, etc., and achieve the effects of low cost of raw materials, simple use method, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] The invention provides a preparation method for preparing a soil remediation stabilizer from high iron tailings. Include the following steps:

[0026] S101: Grinding the high-iron tailings, hydroxyapatite, fly ash, and molybdenite for 1-3 hours respectively, and passing the ground products through a 100-200 mesh sieve. The high-iron tailings are one or more of iron tailings, copper tailings, and vanadium-titanium tailings with an iron element content of 10% to 20%. The main component of molybdenite is MoS 2 , The purity is 90-95%.

[0027] S102: fully mix 40-60 parts by mass of the ground high-speed iron tailings, 10-30 parts by mass of fly ash and 10-20 parts by mass of molybdenite, immerse in strong alkali solution for 1-2 hours, and then sinter. The strong alkali solution is potassium hydroxide or sodium hydroxide solution with a mass concentration of 40%, the sintering temperature is 500-800° C., and the sintering time is 3-5 hours.

[0028] S103: Grinding the s...

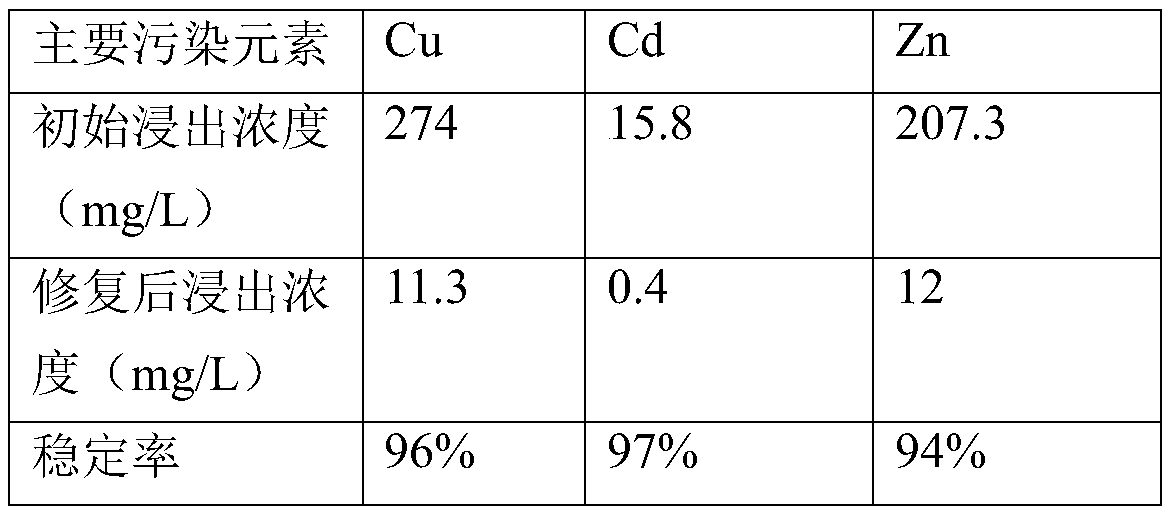

Embodiment 1

[0037] The polluted soil comes from a chemical polluted site left after the relocation of a pesticide factory in Tianjin. Using step S201 to detect it, the main heavy metal pollutants are Cd, Zn, Cu. The high-speed iron tailings are iron tailings from Luanping County, Hebei Province. The main components are shown in Table 1.1. The main component of molybdenite used is MoS 2 , with a purity of 90%.

[0038] Table 1.1: Main components of high iron tailings in Example 1

[0039] all iron

silica

10.55%

41.88%

14.448%

13.362%

[0040] (1) Preparation of soil remediation agent stabilizer:

[0041] S101: Grinding the high-iron tailings, hydroxyapatite, fly ash, and molybdenite for 1 hour respectively, and passing the ground products through a 100-mesh sieve.

[0042] S102: Mix 40 parts by mass of the ground high-speed iron tailings, 20 parts by mass of fly ash, and 20 parts by mass of molybdenite, immerse in a...

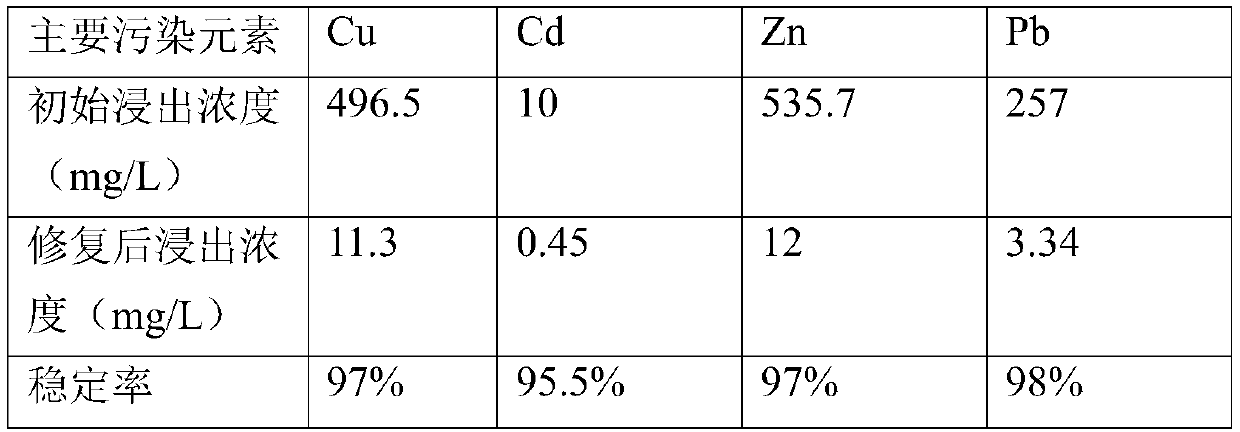

Embodiment 2

[0053] The contaminated soil came from soil contaminated by hazardous waste produced by a metal surface processing factory in Tianjin. Using step S201 to detect it, the main heavy metal pollutants are Cd, Zn, Cu, Pb. The high-speed iron tailings are copper tailings from Luanping County, Hebei Province. The main components are shown in Table 2.1. The main component of molybdenite used is MoS 2 , with a purity of 95%.

[0054] Table 2.1: In Example 2, the main components of high tailings

[0055] all iron

silica

17.15%

52.80%

4.259%

1.154%

[0056] (1) Preparation of soil remediation agent stabilizer:

[0057] S101: Grinding the high-iron tailings, hydroxyapatite, fly ash, and molybdenite for 2 hours respectively, and passing the ground products through a 200-mesh sieve.

[0058] S102: Mix 40 parts by mass of the ground high-speed iron tailings, 10 parts by mass of fly ash, and 20 parts by mass of molybde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com