Modified psyllium seed husk thickening agent used for drilling fluid and preparation method thereof

A technology of psyllium seed husk and drilling fluid, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as environmental impact, and achieve the effects of increasing temperature resistance, significantly improving viscosity and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The concrete preparation method of the present invention comprises the following steps:

[0022] 1. Pretreatment of psyllium seed husk

[0023] (1) Freshen the psyllium seed husks with water, put them in an oven, and dry them at 100℃±5℃ for 5 hours;

[0024] (2) Pulverize the dried psyllium seed husks with a pulverizer, check with a standard inspection sieve, and pulverize to 800 mesh to 1000 mesh, and set aside.

[0025] 2. Preparation of modified psyllium seed husk

[0026] (1) Add 60~80g of pretreated psyllium seed husks into a 500mL three-necked flat-bottomed flask, add 6~10g of NaOH, then slowly add 300g of distilled water, stir at low speed, and after all NaOH is dissolved, heat to 60~ 80°C, continue to stir for 40~60min;

[0027] (2) Slowly add 20~30g NaOH (flaky caustic soda) to the above reactor, stir slowly until all dissolved, then slowly add 50~80g water, keep the temperature at 30~40℃, and continue stirring for 15~20min;

[0028] (3) Add 30~50g of isopr...

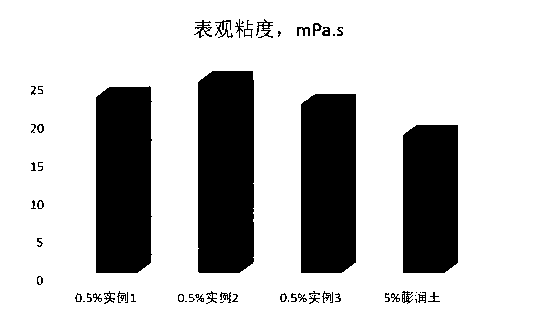

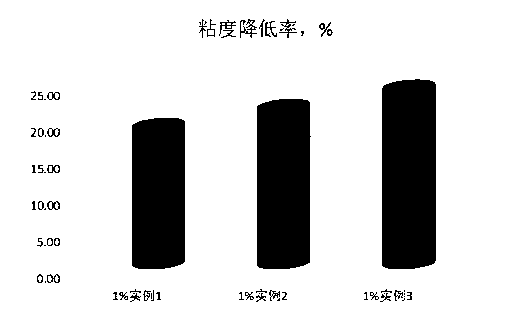

Embodiment 1

[0034] Add 60 g of pretreated psyllium seed husks to a 500 mL three-necked flat-bottomed flask, add 6 g of NaOH, then slowly add 300 g of distilled water, stir at low speed, and after all NaOH is dissolved, heat to 60 ° C, and continue to stir for 40 min; slowly Add 20g NaOH (flaky caustic soda), stir slowly until all dissolved, then slowly add 50g water, keep the temperature at 30°C, and continue stirring for 15min; add 30g isopropanol in the form of dripping, after the dropwise addition, the temperature is kept at 40 ℃, stir at low speed for 30min; add 10g of propylene oxide, keep the temperature at 40℃, stir at low speed for 20min; add 10g of hydrophilic nano-silica SJ-801, continue to stir for 30min; remove the above reaction product by vacuum filtration. The liquid phase is washed with ethanol until the washing liquid is clear; the above product is placed in an oven, dried at 70 ± 5 ° C, and the dried product is pulverized with a pulverizer, tested with a standard inspecti...

Embodiment 2

[0036] Add 70g of pretreated psyllium seed husks to a 500mL three-necked flat-bottomed flask, add 6g of NaOH, then slowly add 300g of distilled water, stir at low speed, after all NaOH is dissolved, heat to 70°C, and continue to stir for 50min; slowly Add 25g NaOH (flaky caustic soda), stir slowly until all dissolved, then slowly add 70g water, keep the temperature at 35°C, and continue stirring for 18min; add 40g of isopropanol in a trickling manner, after the dropwise addition, keep the temperature at 45 ℃, stir at low speed for 40min; add 15g of propylene oxide, keep the temperature at 45℃, stir at low speed for 20min; add 15g of hydrophilic nano-silica SJ-2500, continue to stir for 30min; remove the above reaction product by vacuum filtration. The liquid phase is washed with ethanol until the washing liquid is clear; the above product is placed in an oven, dried at 70 ± 5 ° C, and the dried product is pulverized with a pulverizer, tested with a standard inspection sieve, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com