Preparation method of heptamethine benzoindocyanine dye

A technology for benzindocyanine and benzindole derivatives, which is applied in the field of preparation of polymethine benzindocyanine dyes, can solve the problems of high price, high consumption of organic solvents, low purity and the like, and achieves The effect of improving preparation efficiency, large single reaction volume and simple purification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1 synthetic compound 1

[0093] This embodiment synthesizes compound 1 according to the following route:

[0094]

[0095] (1) Synthesis of 2,3,3-trimethyl-1-(ethyl butyrate)-4,5-benzindole

[0096] Add 2,3,3-trimethyl-4,5-benzindole and ethyl 4-bromobutyrate at a molar ratio of 1:1.5 into the reactor, and heat to 120°C in a closed environment to melt Stir for 10 hours and cool to room temperature. It was recrystallized four times with acetone and dried under vacuum. The yield was 85.9%. It was used in the next reaction without further purification.

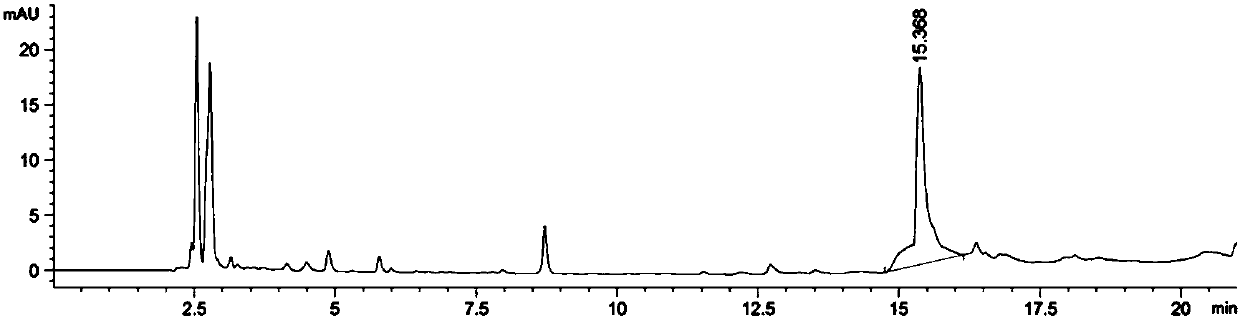

[0097] (2) Synthesis and purification of compound 1

[0098]Add 2-chloro-1-formyl-3-hydroxymethylenecyclohexene, 2,3,3-trimethyl-1-(butyric acid ethyl ester at a molar ratio of 1:2.5:2 to the reactor )-4,5-benzindole and anhydrous sodium acetate, and add ethanol to dissolve completely, then react under reflux in a closed environment (react at 75°C for 24 hours) until the ethanol is completely volatilized,...

Embodiment 2

[0099] Embodiment 2 synthetic compound 7

[0100] This embodiment synthesizes compound 7 according to the following route:

[0101]

[0102] (1) Synthesis of 2,3,3-trimethyl-1-(butanesulfonic acid)-4,5-benzindole

[0103] Add 2,3,3-trimethyl-4,5-benzindole and 1,4-butane sultone in a molar ratio of 1:1.5 into the reactor, and heat to 120°C in a closed environment to melt After melting, stir for 10 hours and cool to room temperature. It was recrystallized four times with acetone and dried in vacuo. The yield was 83.7%. It was used in the next reaction without further purification.

[0104] (2) Synthesis and purification of compound 7

[0105] Add 2-chloro-1-formyl-3-hydroxymethylenecyclohexene, 2,3,3-trimethyl-1-(butanesulfonic acid) in a molar ratio of 1:2.5:2 to the reactor -4,5-benzindole and anhydrous sodium acetate, and add ethanol to dissolve completely, then react in a closed environment under reflux (react at 75°C for 24 hours) until the ethanol is completely vol...

Embodiment 3

[0106] Embodiment 3 synthetic compound C1

[0107] This embodiment synthesizes compound C1 according to the following route:

[0108]

[0109] (1) Synthesis of 2,3,3-trimethyl-1-(butyramide)-4,5-benzindole

[0110] Add 2,3,3-trimethyl-4,5-benzindole and 4-bromobutyramide in a molar ratio of 1:1.5 into the reactor, heat to 120°C in a closed environment and stir for 10 hours after melting, Cool to room temperature. It was recrystallized four times with acetone and dried in vacuo. The yield was 85.7%. It was used in the next reaction without further purification.

[0111] (2) Synthesis and purification of compound C1

[0112] Add 2-chloro-1-formyl-3-hydroxymethylenecyclohexene, 2,3,3-trimethyl-1-(butanamide)- 4,5-benzindole and anhydrous sodium acetate, and add ethanol to dissolve completely, then react in a closed environment under reflux (75°C for 24 hours) to completely evaporate the ethanol, add methanol to dissolve and then mix with Petroleum ether was extracted and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com