Antistatic and antibacterial fabric master batch and preparing method thereof

An antibacterial fabric and antistatic technology, applied in the field of antistatic antibacterial fabric masterbatch and its preparation, can solve the problems of toxic products and toxic coupling agents, and achieve the effects of enhancing binding force, improving antibacterial ability and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

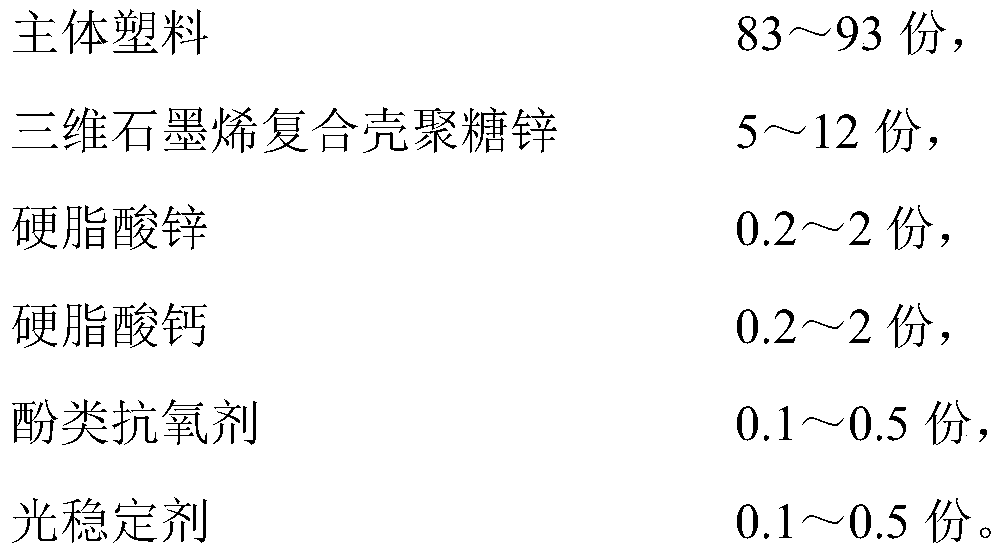

[0050] Antistatic antibacterial underwear fabric masterbatch

[0051] raw material:

[0052]

[0053] Preparation of 3D graphene:

[0054] (1) Take 8 parts of acrylic acid cation exchange resin (macroporous, weak acid type) in a beaker, add 92 parts of 0.05 mol / L nickel acetate solution, and magnetically stir for 6 hours to obtain reaction system C.

[0055] (2) The solid obtained in reaction system C was filtered, washed several times with deionized water, and dried at 60° C. for 12 hours to obtain product D.

[0056] (3) In 60 parts of product D containing 40 parts of KOH in ethanol solution, stirred at 80° C. for 6 hours to obtain pasty product E.

[0057] (4) The pasty product E was dried at 70° C. for 48 hours and pulverized to obtain product F.

[0058] (5) The product F was placed in a tube furnace, under the protection of 60 mL / min nitrogen flow, slowly raised to 850 °C at 2 °C / min, heated at 850 °C for 2 hours, and then cooled to room temperature to obtain produ...

Embodiment 2

[0067] Antistatic antibacterial underwear fabric masterbatch

[0068] raw material:

[0069]

[0070] Preparation of 3D graphene:

[0071] (1) Take 12 parts of acrylic acid cation exchange resin (macroporous, weak acid type) in a beaker, add 88 parts of 0.05 mol / L nickel acetate solution, and magnetically stir for 6 hours to obtain reaction system C.

[0072] (2) The solid obtained in reaction system C was filtered, washed several times with deionized water, and dried at 60° C. for 12 hours to obtain product D.

[0073] (3) Add ethanol solution containing 30 parts of KOH to 70 parts of product D, and stir at 80° C. for 6 hours to obtain pasty product E.

[0074] (4) The pasty product E was dried at 70° C. for 48 hours and pulverized to obtain product F.

[0075] (5) The product F was placed in a tube furnace, under the protection of 60 mL / min nitrogen flow, slowly raised to 850 °C at 2 °C / min, heated at 850 °C for 2 hours, and then cooled to room temperature to obtain pr...

Embodiment 3

[0084] Antistatic antibacterial underwear fabric masterbatch

[0085] raw material:

[0086]

[0087] Preparation of 3D graphene:

[0088] (1) Take 10 parts of acrylic acid cation exchange resin (macroporous, weak acid type) in a beaker, add 90 parts of 0.05 mol / L nickel acetate solution, and magnetically stir for 6 hours to obtain reaction system C.

[0089] (2) The solid obtained in reaction system C was filtered, washed several times with deionized water, and dried at 60° C. for 12 hours to obtain product D.

[0090] (3) Add an ethanol solution containing 35 parts of KOH to 65 parts of product D, and stir at 80° C. for 6 hours to obtain pasty product E.

[0091] (4) The pasty product E was dried at 70° C. for 48 hours and pulverized to obtain product F.

[0092] (5) The product F was placed in a tube furnace, under the protection of 60 mL / min nitrogen flow, slowly raised to 850 °C at 2 °C / min, heated at 850 °C for 2 hours, and then cooled to room temperature to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com