A kind of low yi value nylon composite material and preparation method thereof

A nylon composite material and composite material technology are applied in the field of low YI value nylon composite material and its preparation, which can solve the problems of poor anti-oxidation effect and the like, and achieve the effect of low YI value and white product color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

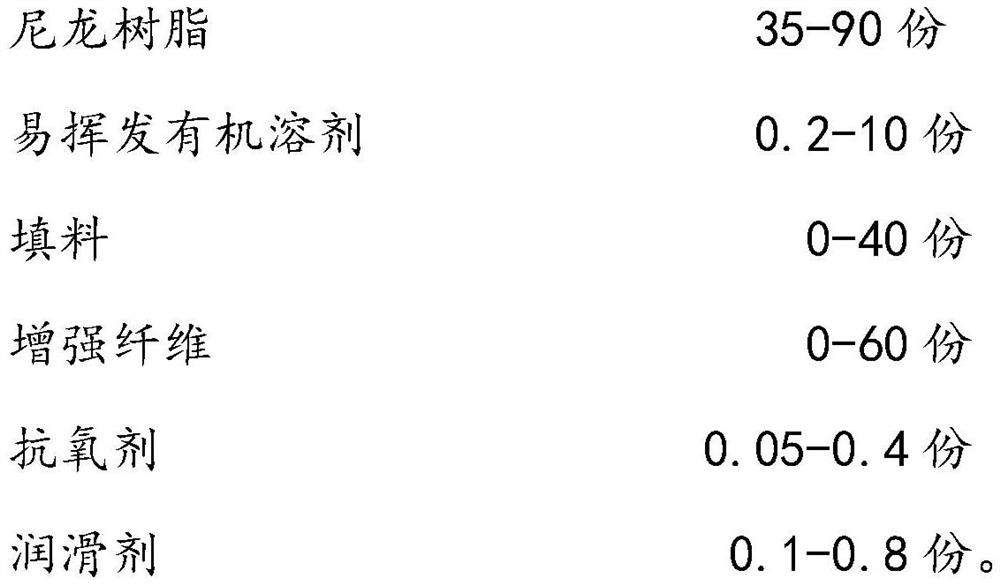

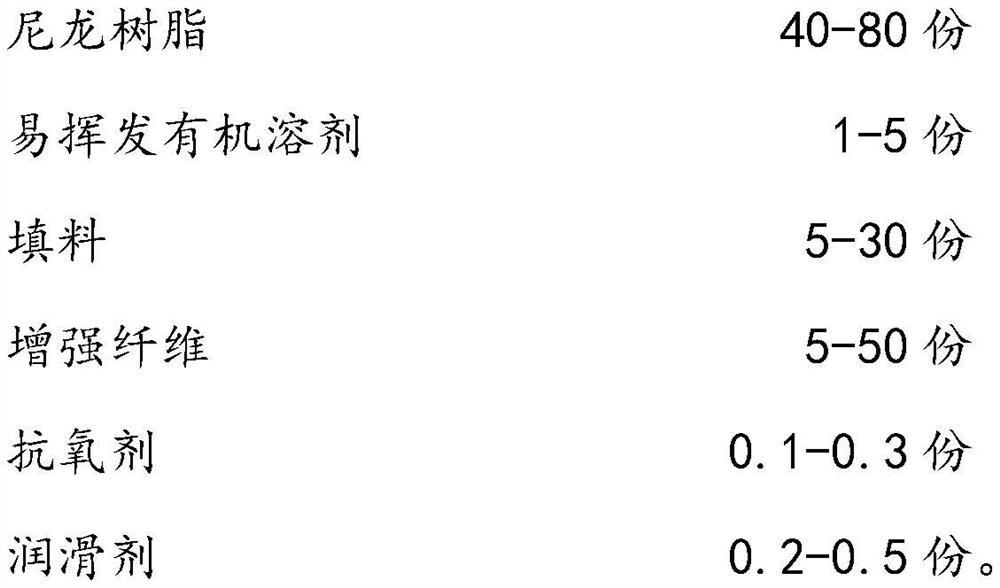

Method used

Image

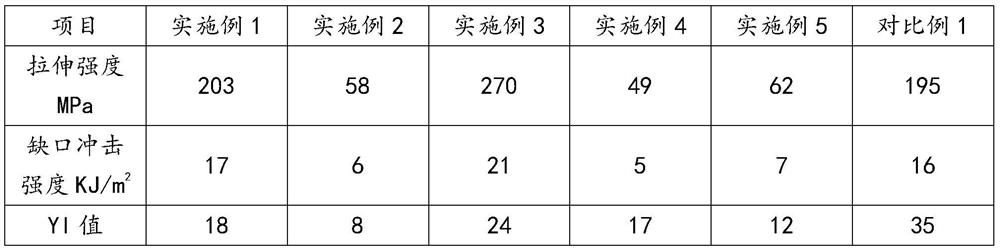

Examples

Embodiment 1

[0024] S10. Add 60 parts of dry nylon resin polyhexamethylene adipamide (PA66), 3 parts of methylene chloride, 0.1 part of antioxidant 1098, 0.1 part of antioxidant 168, and 0.4 part of lubricant zinc stearate into the high-speed Mix evenly in a mixer to obtain a mixture; in this step, the dried nylon resin PA66 is obtained by blowing and drying nylon resin PA66 at 100°C for 6 hours; the speed of the high-speed mixer is 600r / min, and the mixing time is 4min;

[0025] S20. Add the mixture into the twin-screw extruder from the main feed port of the twin-screw extruder, and add 40 parts of alkali-free glass fiber to the twin-screw extruder from the side feed port of the twin-screw extruder. In the extruder, the low YI value nylon PA66 composite material is obtained after drawing, cooling, pelletizing and drying; in this step, the twin-screw extruder adopts zone temperature control, the temperature of the first zone is 255°C, and the temperature of the second zone is 260°C , the t...

Embodiment 2

[0027] S10. Add 60 parts of dry nylon resin polycaprolactam (PA6), 10 parts of tetrahydrofuran, 40 parts of titanium dioxide, 0.4 parts of antioxidant 1790, 0.2 parts of antioxidant S9228, and 0.8 parts of lubricant silicone into a high-speed mixer and mix Evenly, the mixture is obtained; in this step, the dry nylon resin PA6 is obtained by blowing and drying the nylon resin PA6 at 60°C for 12 hours; the speed of the high-speed mixer is 800r / min, and the mixing time is 2min;

[0028] S20, the mixture is added into the twin-screw extruder from the main feeding port of the twin-screw extruder, and a low YI value nylon PA6 composite material is obtained after drawing, cooling, pelletizing and drying; in this step, the double The screw extruder adopts zone temperature control, the temperature of the first zone is 225°C, the temperature of the second zone is 230°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 240°C, the temperature of the fifth z...

Embodiment 3

[0030] S10, 40 parts of dry nylon resin polyhexamethylene terephthalamide / hexamethylene isophthalamide (PA6T / 6I), 1 part of toluene, 0.1 part of antioxidant H161, 0.2 part of lubrication The polyethylene wax is added into the high-speed mixer and mixed evenly to obtain the mixture; in this step, the dry nylon resin PA6T / 6I is obtained by blowing and drying the nylon resin PA6T / 6I at 140°C for 4 hours; the speed of the high-speed mixer is 300r / min, the mixing time is 10min;

[0031] S20. Add the mixture into the twin-screw extruder from the main feed port of the twin-screw extruder, and add 60 parts of alkali-free glass fiber into the twin-screw extruder from the side feed port of the twin-screw extruder. In the extruder, the nylon PA6T / 6I composite material with low YI value is obtained after drawing, cooling, pelletizing and drying. The temperature in the third zone is 320°C, the temperature in the fourth zone is 325°C, the temperature in the fifth zone is 330°C, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com