Preparing method for microwave absorbing material based on fly ash

A technology of microwave absorbing materials and fly ash, which is applied in the production of ceramic materials, clay products, applications, etc., can solve the problems of difficult to achieve large-scale production and application, high requirements for production equipment, complex process, etc., and achieve high adsorption activity, Inexpensive and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

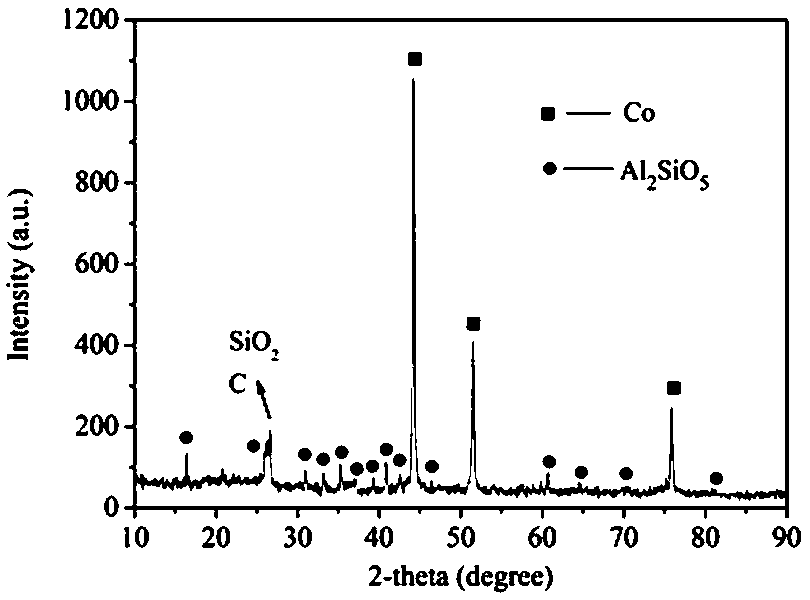

Image

Examples

Embodiment 1

[0027] A preparation method of microwave absorbing material based on fly ash, comprising the following steps:

[0028] S1. Sieve the fly ash through a 300-mesh standard sieve, and dry it at a constant temperature at 110°C for 5 hours;

[0029] S2. Weigh fly ash powder and soluble starch (mass ratio accounts for 30% of the fly ash powder) and place them in an EIRICH intensive mixer to stir evenly to make mixed raw material powder;

[0030] S3. Weigh the deionized water and mixed raw material powder according to the mass ratio of 1:7, put them in the Eilixu powerful mixer and process them into ceramic raw meal balls, then dry the ceramic raw meal balls at 100°C, pass through the sieve Divide into fly ash-based ceramic microspheres with a particle size of 0.2-0.8 mm;

[0031] S4. Dissolving cobalt salts (one or more of cobalt nitrate, cobalt sulfate or cobalt chloride) in deionized water to make a 2+ The precursor solution, the mass of cobalt salt and the volume ratio of deioni...

Embodiment 2

[0035] A preparation method of microwave absorbing material based on fly ash, comprising the following steps:

[0036] S1. Sieve the fly ash through a 300-mesh standard sieve, and dry it at a constant temperature at 100°C for 6 hours;

[0037] S2. Weigh fly ash powder and soluble starch (mass ratio accounts for 20% of the fly ash powder) and place them in the EIRICH intensive mixer to stir evenly to make mixed raw material powder;

[0038] S3. Weigh the deionized water and mixed raw material powder according to the mass ratio of 1:7, put them in the Ailixu powerful mixer and process them into ceramic raw meal balls, then dry the ceramic raw meal balls at 100°C, pass through the sieve Divide into fly ash-based ceramic microspheres with a particle size of 0.2-0.8 mm;

[0039] S4. Dissolving cobalt salts (one or more of cobalt nitrate, cobalt sulfate or cobalt chloride) in deionized water to make a 2+ The precursor solution, the mass of cobalt salt and the volume ratio of deion...

Embodiment 3

[0043] A preparation method of microwave absorbing material based on fly ash, comprising the following steps:

[0044]S1. Sieve the fly ash through a 300-mesh standard sieve, and dry it at a constant temperature at 100°C for 6 hours;

[0045] S2. Weigh fly ash powder and soluble starch (mass ratio accounts for 30% of the fly ash powder) and place them in an EIRICH intensive mixer to stir evenly to make mixed raw material powder;

[0046] S3. Weigh the deionized water and mixed raw material powder according to the mass ratio of 1:7, put them in the Eilixu powerful mixer and process them into ceramic raw meal balls, then dry the ceramic raw meal balls at 100°C, pass through the sieve Divide into fly ash-based ceramic microspheres with a particle size of 0.2-0.8 mm;

[0047] S4. Dissolving cobalt salts (one or more of cobalt nitrate, cobalt sulfate or cobalt chloride) in deionized water to make a 2+ The precursor solution, the mass of cobalt salt and the volume ratio of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com