Artificial lightweight material and preparation method and application thereof

A lightweight material, artificial technology, applied in the field of building materials, can solve the problems of shortage of high-quality materials, low thermal conductivity, large specific gravity, etc., to achieve the effects of environmental protection, wide range of uses, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

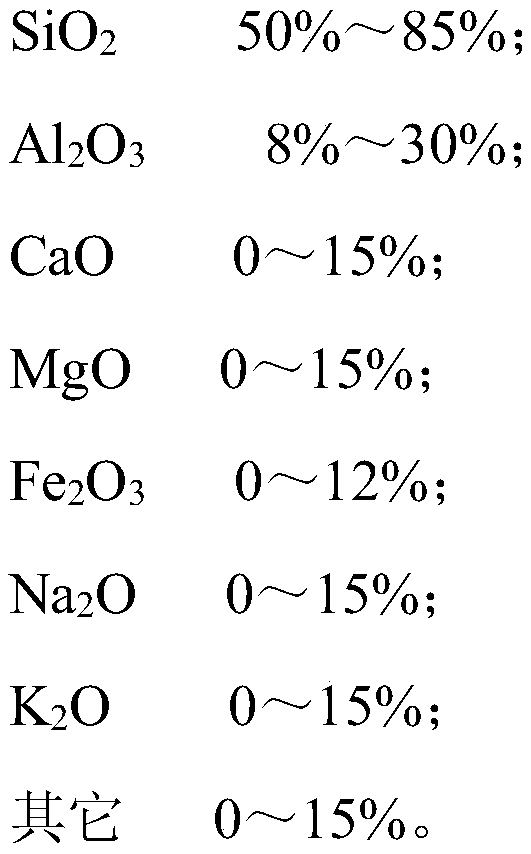

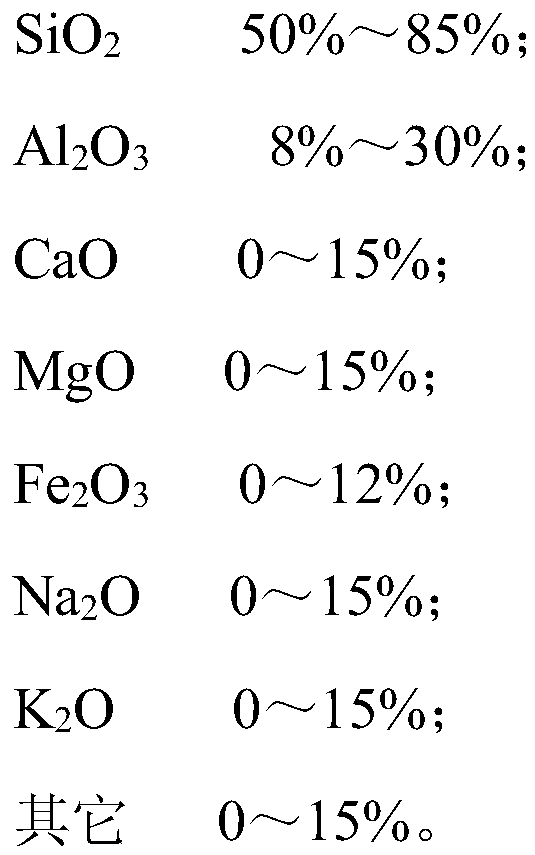

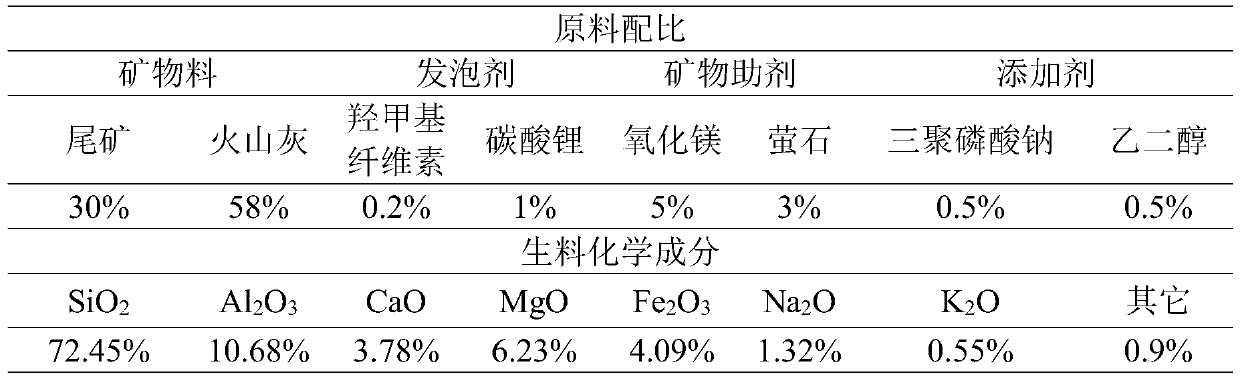

[0033] The raw material ratio and raw material chemical composition of artificial lightweight materials are shown in Table 1:

[0034] Table 1 Raw material ratio and chemical composition of artificial lightweight material 1

[0035]

[0036] The artificial lightweight material is prepared according to the following steps:

[0037] 1. Select the raw materials shown in Table 1.

[0038] 2. Mix the raw materials selected in step 1 according to the proportion shown in Table 1, grind them in a ball mill, pass through a 300-mesh sieve, and control the sieve residue to be less than 10%, so as to obtain raw meal powder.

[0039] 3. Stamping the raw meal powder prepared in step 2.

[0040] 4. Sinter the shaped raw meal prepared in step 3 in a tunnel kiln, set the maximum firing temperature to 1200°C, and the heating rate to 15°C / min.

[0041] 5. Naturally cool the material obtained in step 4 to obtain artificial lightweight material 1.

[0042] 6. Cut the artificial lightweight ...

Embodiment 2

[0044] The raw material ratio and raw material chemical composition of artificial lightweight materials are shown in Table 2:

[0045] Table 2 Raw material ratio and chemical composition of artificial lightweight material 2

[0046]

[0047] The artificial lightweight material is prepared according to the following steps:

[0048] 1. Select the raw materials shown in Table 2.

[0049] 2. Mix the raw materials selected in step 1 according to the proportion shown in Table 1, grind them in a ball mill, pass through a 300-mesh sieve, and control the sieve residue to be less than 10%, so as to obtain raw meal powder.

[0050] 3. Extrude the raw meal powder prepared in step 2.

[0051] 4. The shaped raw meal prepared in step 3 is sintered in a roller kiln, the maximum firing temperature is set to 1200° C., and the heating rate is 15° C. / min.

[0052] 5. Naturally cool the material obtained in step 4 to obtain the artificial lightweight material 2.

[0053] 6. Cut the artifici...

Embodiment 3

[0055] The raw material ratio and raw material chemical composition of artificial lightweight materials are shown in Table 3:

[0056] Table 3 Raw material ratio and chemical composition of artificial lightweight material 3

[0057]

[0058] The artificial lightweight material is prepared according to the following steps:

[0059] 1. Select the raw materials shown in Table 3.

[0060] 2. Mix the raw materials selected in step 1 according to the proportion shown in Table 1, grind them in a ball mill, pass through a 300-mesh sieve, and control the sieve residue to be less than 10%, so as to obtain raw meal powder.

[0061] 3. Extrude the raw meal powder prepared in step 2.

[0062] 4. Sinter the shaped raw meal prepared in step 3 in a 1m3 shuttle kiln, set the maximum firing temperature to 1180°C, and the heating rate to 18°C / min.

[0063] 5. Naturally cool the material obtained in step 4 to obtain artificial lightweight material 3.

[0064] 6. Crushing and screening the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com