Lithium ion battery binding agent and preparation method and application thereof

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance, pole piece cracks, insufficient toughness, etc., and achieve low cost, simple operation, and easy industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The embodiment of the present invention provides a kind of preparation method of lithium ion battery binder, comprises the following steps:

[0046] S10. Obtain multi-component small molecules, initiators and monomers, wherein the monomers are selected from acrylic monomers or non-acrylic monomers;

[0047] S20. Mixing and dissolving the multi-component small molecules, initiators and monomers in a liquid medium, and performing a polymerization reaction to obtain a crude product;

[0048] S30. When the monomer is an acrylic monomer, purify the crude product to obtain a non-linear lithium ion battery binder; when the monomer is a non-acrylic monomer, purify the crude product After purification, it is converted and purified again to obtain a non-linear lithium ion battery binder.

[0049] The preparation method of the lithium-ion battery binder provided in the embodiment of the present invention takes the multi-component small molecule as the core, and under the action o...

Embodiment 1

[0077] S10. 10mM trimethylolpropane bromide, PEMTA / CuBr (pentamethyldiethylenetriamine / copper bromide) (30mM / 30mM) initiator and 5M tert-butyl methacrylate monomer were dried Under an inert gas atmosphere, use the solvent DMF in the reaction kettle to stir and dissolve at a stirring speed of 300-500rpm to obtain a solution;

[0078] S20. Raise the reaction temperature to 80° C. with a stirring speed of 300 rpm under a dry inert gas atmosphere, and react the solution for 24 hours. After cooling, a crude product is obtained;

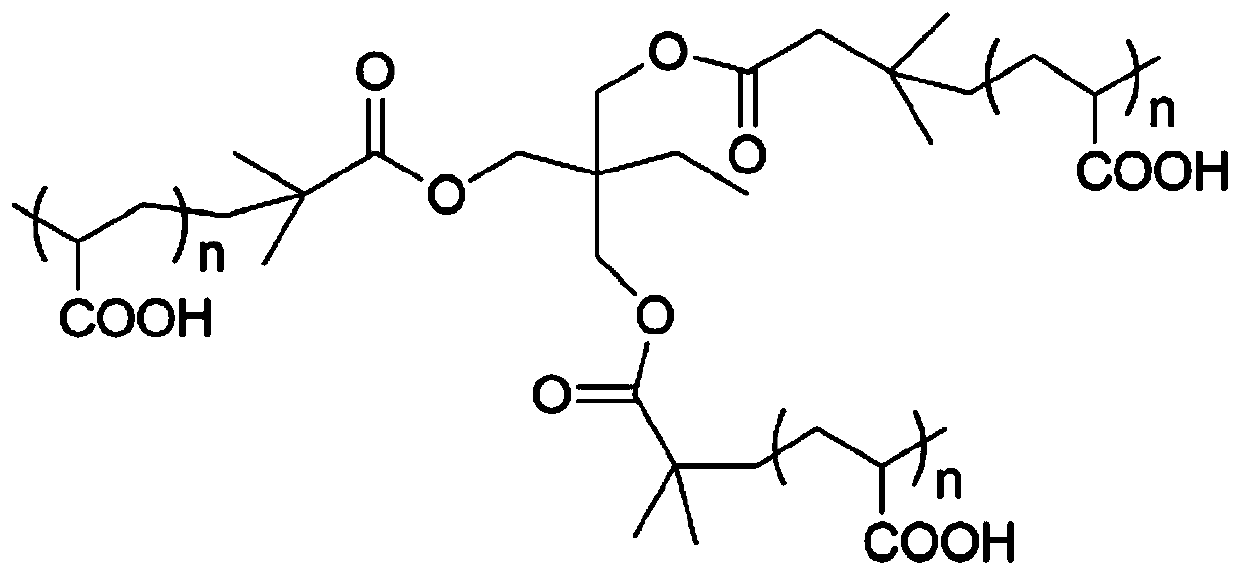

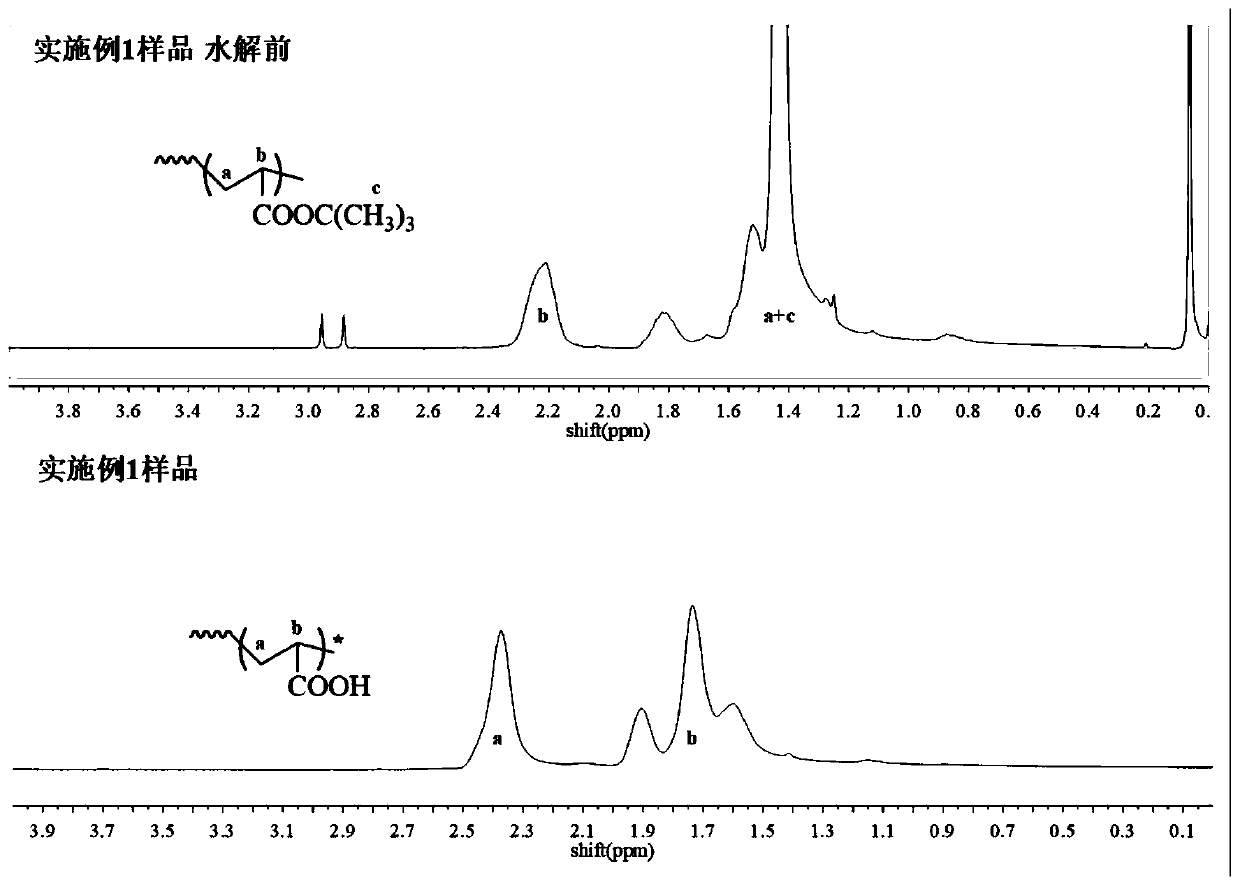

[0079] S30. The crude product is repeatedly dissolved and precipitated with good and bad solvents for purification; then the purified multi-arm (3-arm) poly-tert-butyl methacrylate is hydrolyzed under the action of trifluoroacetic acid; finally, the product is dialyzed and freeze-dried Obtain the nonlinear lithium ion battery binder 1, the molecular structure is as attached figure 1 mentioned.

Embodiment 2

[0081] S10. Dissolve 10mM pentaerythritol, 40M cerium ammonium nitrate initiator and 20M acrylonitrile monomer in a reaction kettle with solvent water 5 times the volume of the monomer at a stirring speed of 300-500rpm to obtain a solution;

[0082] S20. Raise the reaction temperature of the solution to 40° C., the stirring speed is 300 rpm, and react for 24 hours. After cooling, a crude product is obtained;

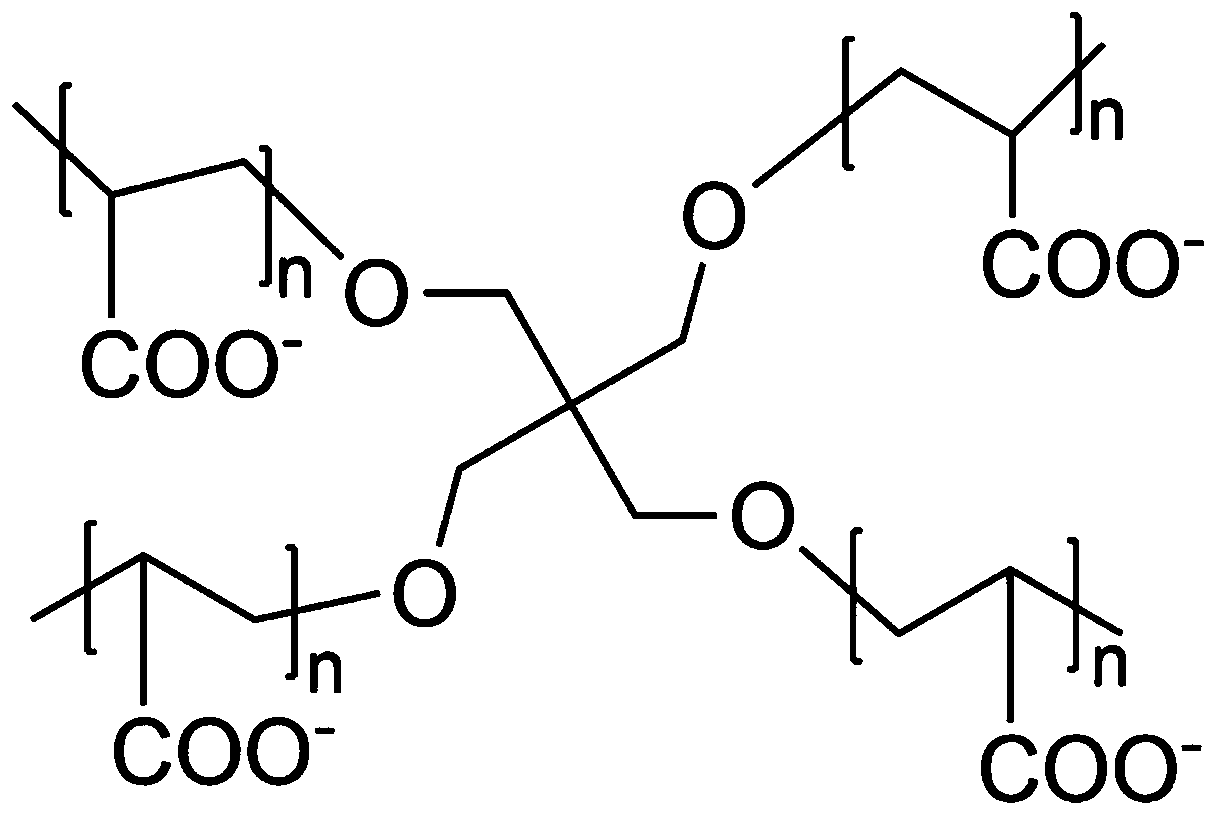

[0083] S30. The crude product is repeatedly dissolved, precipitated and purified with good and bad solvents; then the purified multi-arm (4-arm) polyacrylonitrile is hydrolyzed with 1M LiOH; finally, the product is dialyzed and freeze-dried to obtain a non-linear lithium ion battery. Binder 2, molecular structure as attached figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com