Composite anode material for lithium battery, and preparation method of composite anode material

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as large loss of composite specific capacity, inability to distribute aluminum phosphate evenly, surface erosion of matrix materials, etc. Cycle performance and safety performance, floating charge performance time and high temperature storage performance improvement, the effect of strong electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

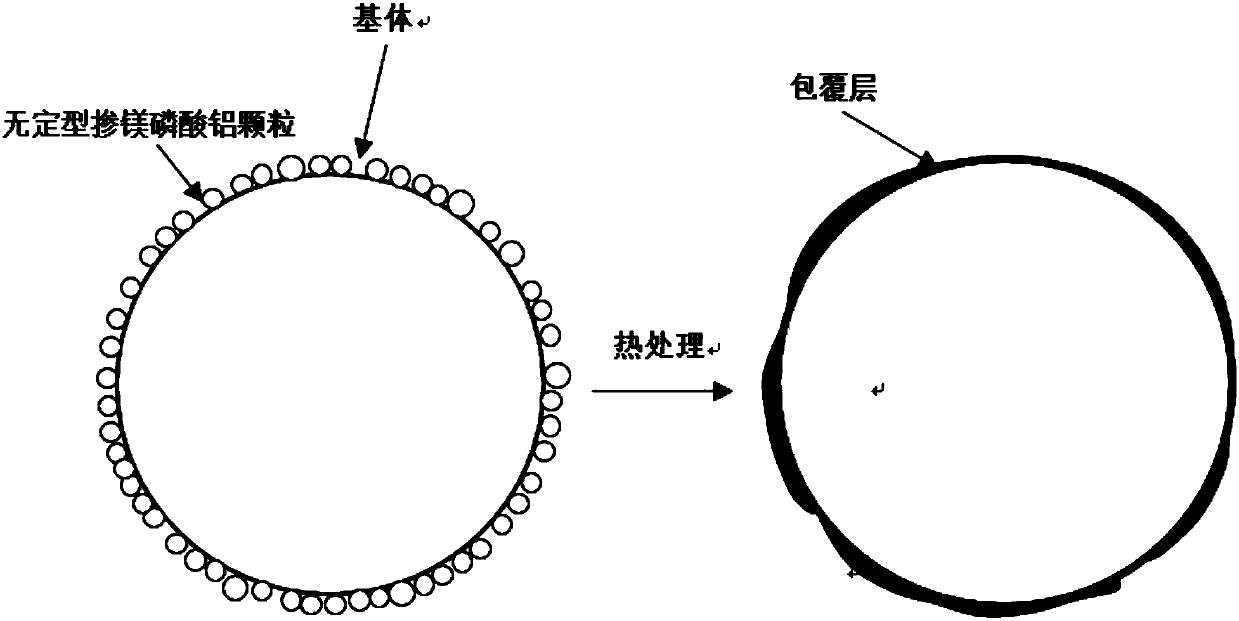

[0039] A kind of composite cathode material of lithium ion battery of the present invention, with lithium cobalt oxide material (molecular formula is Li 1.01 co 0.995 Mg 0.002 al 0.002 Ti 0.001 o 2 ) is a substrate, and a magnesium-doped aluminum phosphate layer is coated on the surface of the substrate, wherein the magnesium-doped aluminum phosphate layer is a magnesium-doped aluminum phosphate layer with high crystallinity; the mass fraction of the magnesium-doped aluminum phosphate layer in the substrate is 0.5% .

[0040] The preparation method of the lithium ion battery composite cathode material of the present embodiment comprises the following steps:

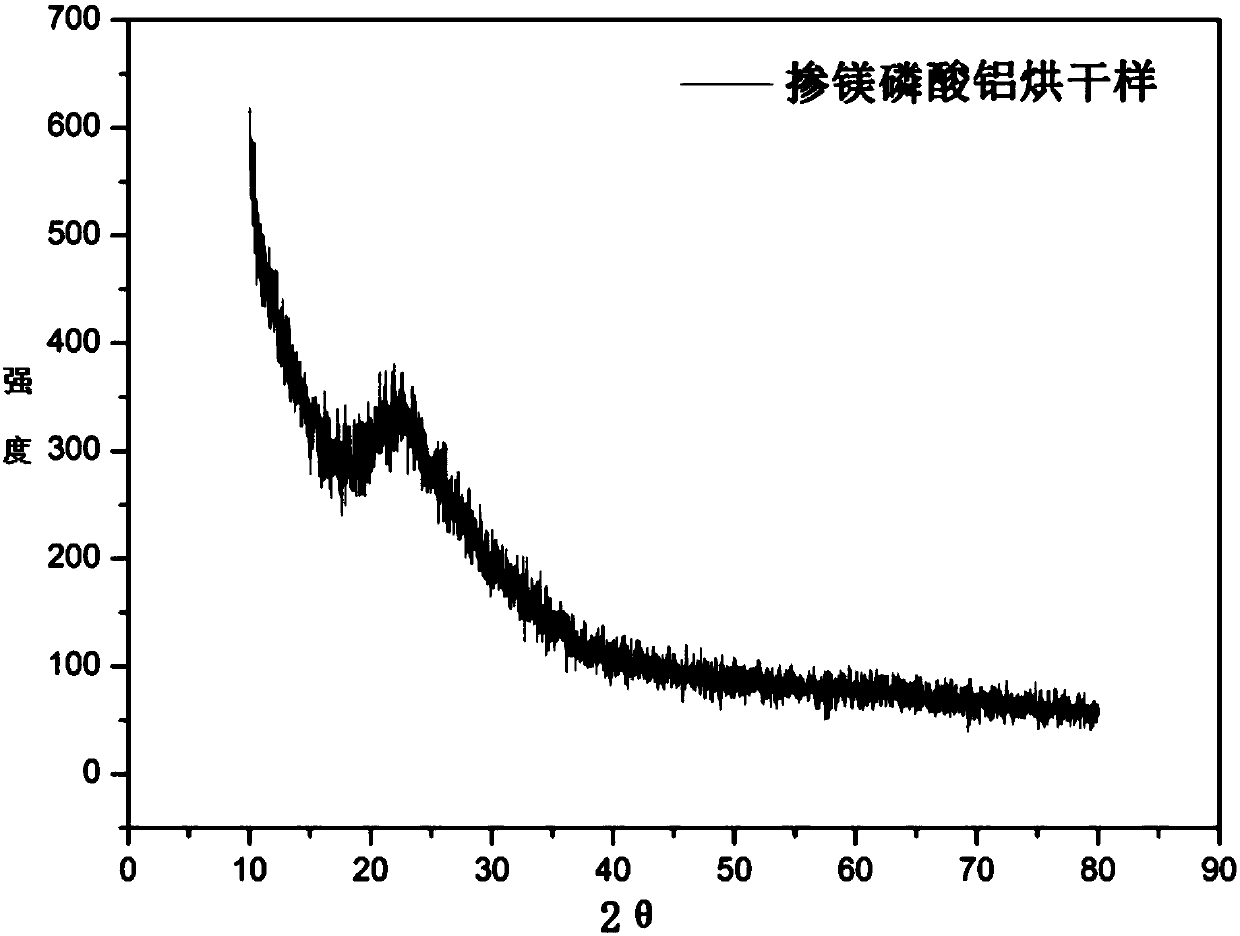

[0041] (1) Take 20g Al(NO 3 ) 3 9H 2 O and 2.42g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 400mL water to obtain a solution A with a cation concentration of 0.16mol / L;

[0042] (2) Take 7.86g (NH 4 ) 2HPO 4 Dissolve in 400mL water to obtain solution B with anion concentration of 0.15mol / L;

[0043] (3) Under th...

Embodiment 2

[0059] A lithium-ion battery composite positive electrode material of the present invention, which uses lithium cobaltate material as a matrix, and coats a magnesium-doped aluminum phosphate layer on the surface of the matrix, wherein the magnesium-doped aluminum phosphate layer is a high-crystallinity magnesium-doped aluminum phosphate layer , the mass fraction of the nano-doped magnesium aluminum phosphate layer in the matrix is 0.8%; the molecular formula of the lithium cobalt oxide material is Li 1.034 co 0.995 Mg 0.002 al 0.002 Ti 0.001 o 2 .

[0060] The preparation method of the lithium ion battery composite cathode material of the present embodiment comprises the following steps:

[0061] (1) Take 30g Al(NO 3 ) 3 9H 2 O and 1.08g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 200 mL of water to obtain a solution A with a cation concentration of 0.42 mol / L;

[0062] (2) Take 10.93g (NH 4 ) 2 HPO 4 Dissolve in 200mL water to obtain solution B with anion concentrat...

Embodiment 3

[0069] A kind of composite cathode material of lithium ion battery of the present invention, with lithium cobalt oxide material (molecular formula is Li 0.99 co 0.995 Mg 0.002 al 0.002 Ti 0.001 o 2 ) is a substrate, and a layer of magnesium-doped aluminum phosphate layer is coated on the surface of the substrate, wherein the nano-magnesium-doped aluminum phosphate layer is magnesium-doped aluminum phosphate with high crystallinity, and the coating amount of nano-magnesium-doped aluminum phosphate is 1%.

[0070] The preparation method of the lithium ion battery composite cathode material of the present embodiment comprises the following steps:

[0071] (1) Take 30g Al 2 (SO 4 ) 3 and 2.11 g MgSO 4 Dissolve in 1L of water to obtain a solution A with a cation concentration of 0.1mol / L;

[0072] (2) Take 13g (NH 4 ) 2 HPO 4 Dissolve in 1L of water to obtain solution B with anion concentration of 0.1mol / L;

[0073] (3) Under the condition of stirring, inject solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com