Online detection equipment for ore granularity based on a map image algorithm analysis technology

A technology of image algorithm and analysis technology, which is applied in the field of online detection equipment for ore particle size, can solve the problems of high energy consumption, time-consuming, and laborious, etc., and achieve the effect of improving the degree of dissociation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

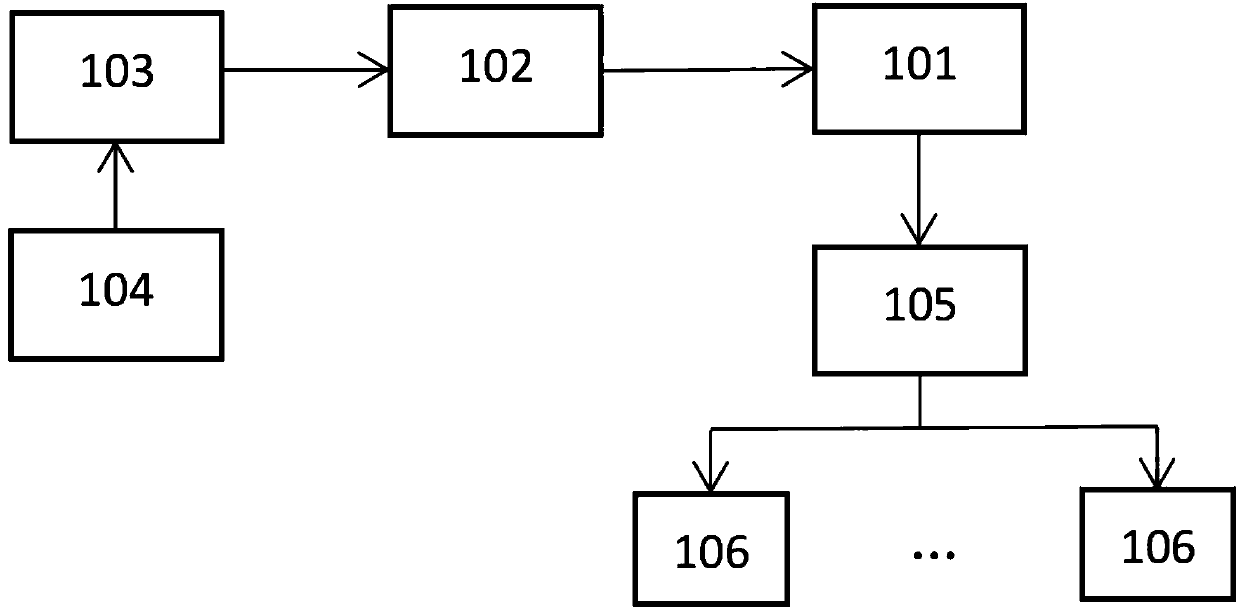

[0032] This embodiment provides an online ore particle size detection system based on graph image algorithm analysis technology, which includes an industrial computer 101, a local area network switch 102, a local area network 103, an ore particle size analyzer 104, the Internet 105, and multiple clients 106. In the embodiment, the local area network is a Gigabit dedicated network, and the local area network switch is a Gigabit switch; the industrial computer 101 is connected to the local area network switch 102, and is connected to the ore particle size analyzer 104 through the local area network 103. In addition, the industrial computer 101 is also connected to the ore particle size analyzer 104 through the Internet 105. Multiple clients 106 are connected.

[0033] The ore particle size analyzer 104 is installed directly above the ore conveyor belt. By adjusting various parameters of the ore particle size analyzer 104, including camera focal length, camera exposure time, bracket ...

Embodiment 2

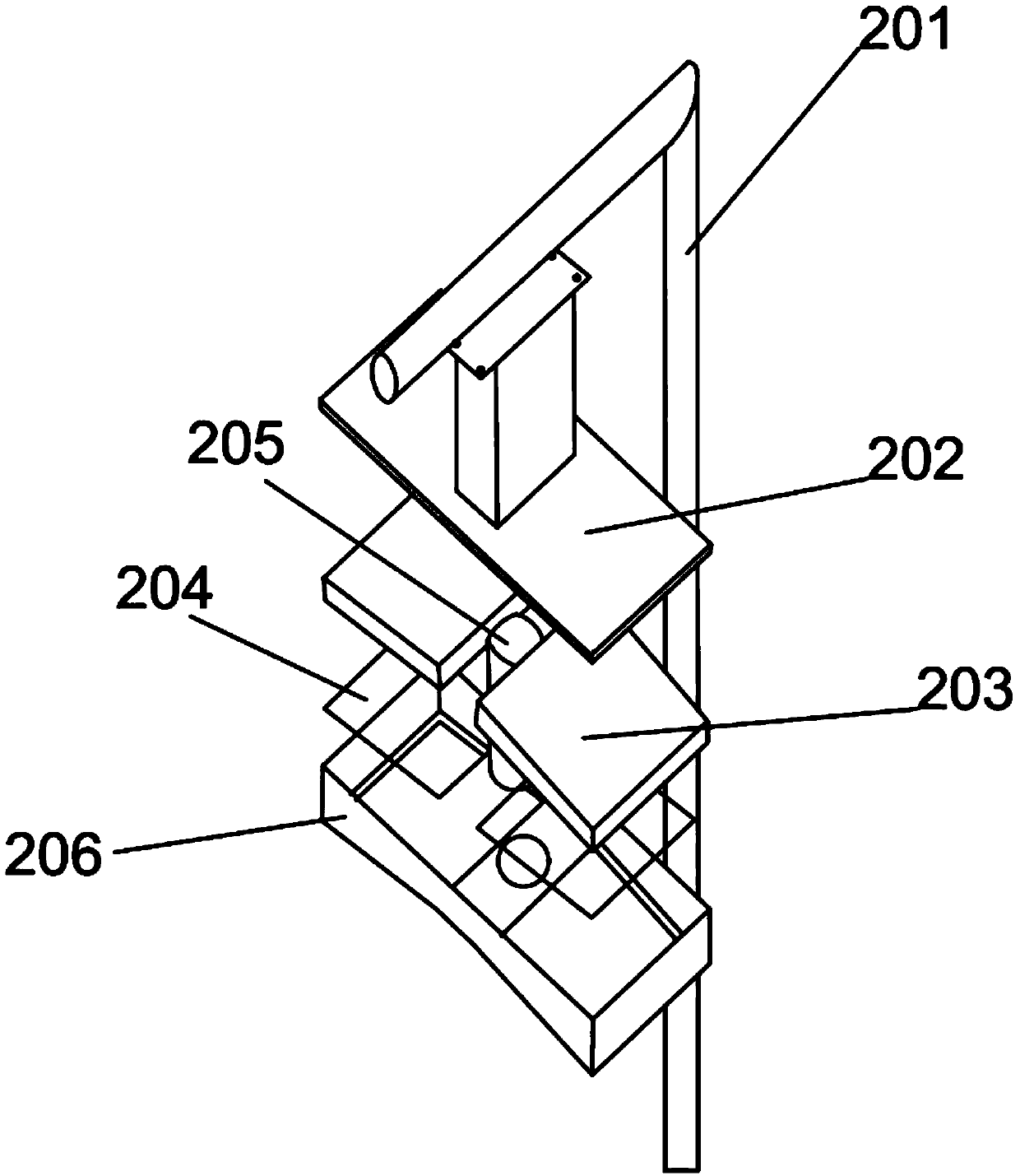

[0038] This embodiment provides the structure of the ore particle size analyzer in embodiment 1, such as figure 2 As shown, the bracket 201 includes an upper housing 202, a high-brightness soft-light LED lamp 203, a high-transmittance tempered glass 204, an image acquisition instrument 205, and a lower housing 206.

[0039] The bracket 201 is installed near the conveyor belt to fix the ore particle size analyzer 104 above the conveyor belt to take pictures of the ore on the conveyor belt. The shape and size of the bracket 201 can be determined according to site conditions. In this embodiment, the support 201 is L-shaped, the vertical part of which is fixed on the ground, and the horizontal part extends on the conveyor belt, and other parts of the ore particle size analyzer 104 are fixed on the support 201 through a U-shaped pipe clamp and hexagonal nuts. The upper shell 202 is a one-piece metal plate, and the lower shell 206 has a five-sided structure as shown in the figure. The ...

Embodiment 3

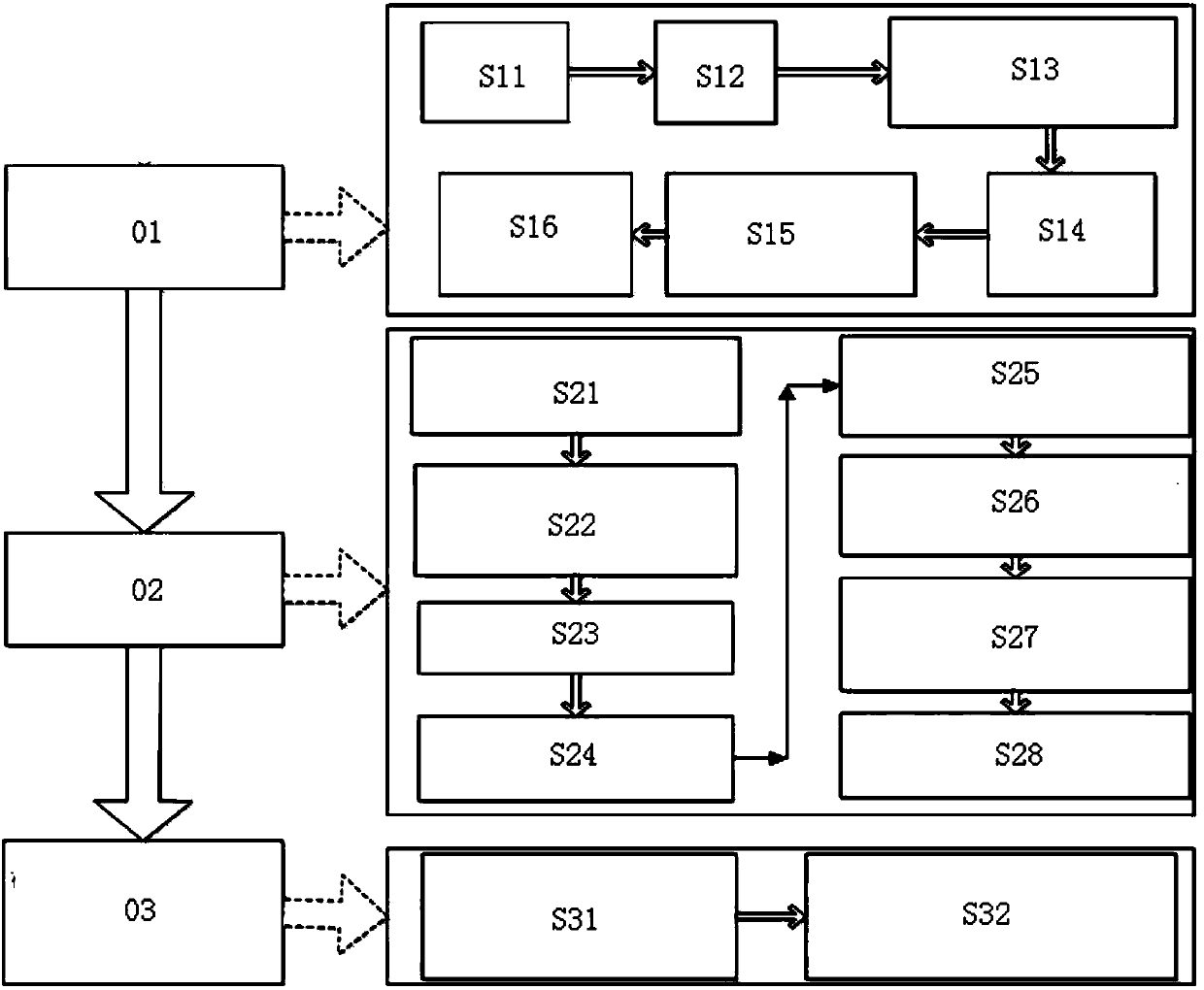

[0041] This example provides the composition and analysis method of the ore particle size analysis system in Example 1, such as image 3 As shown, the ore particle size analysis system consists of an image preprocessing module 01, an image segmentation module 02, a size calibration and modeling analysis module 03 installed on an industrial computer. The ore particle size analysis system receives the real-time collected ore image transmitted by the ore particle size analyzer 104 and performs image processing, thereby calculating the distribution and pass rate of the ore particle size, and the maximum ore particle size;

[0042] According to an embodiment of the present invention, the real-time image acquisition and processing flow for ore particle size analysis includes the following steps:

[0043] 1. The image preprocessing module 01 preprocesses the collected ore image transmitted by the communication line. The specific preprocessing includes: step S11, perform texture analysis on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com